DTF gangsheet builder: 5 must-have features for pro-quality

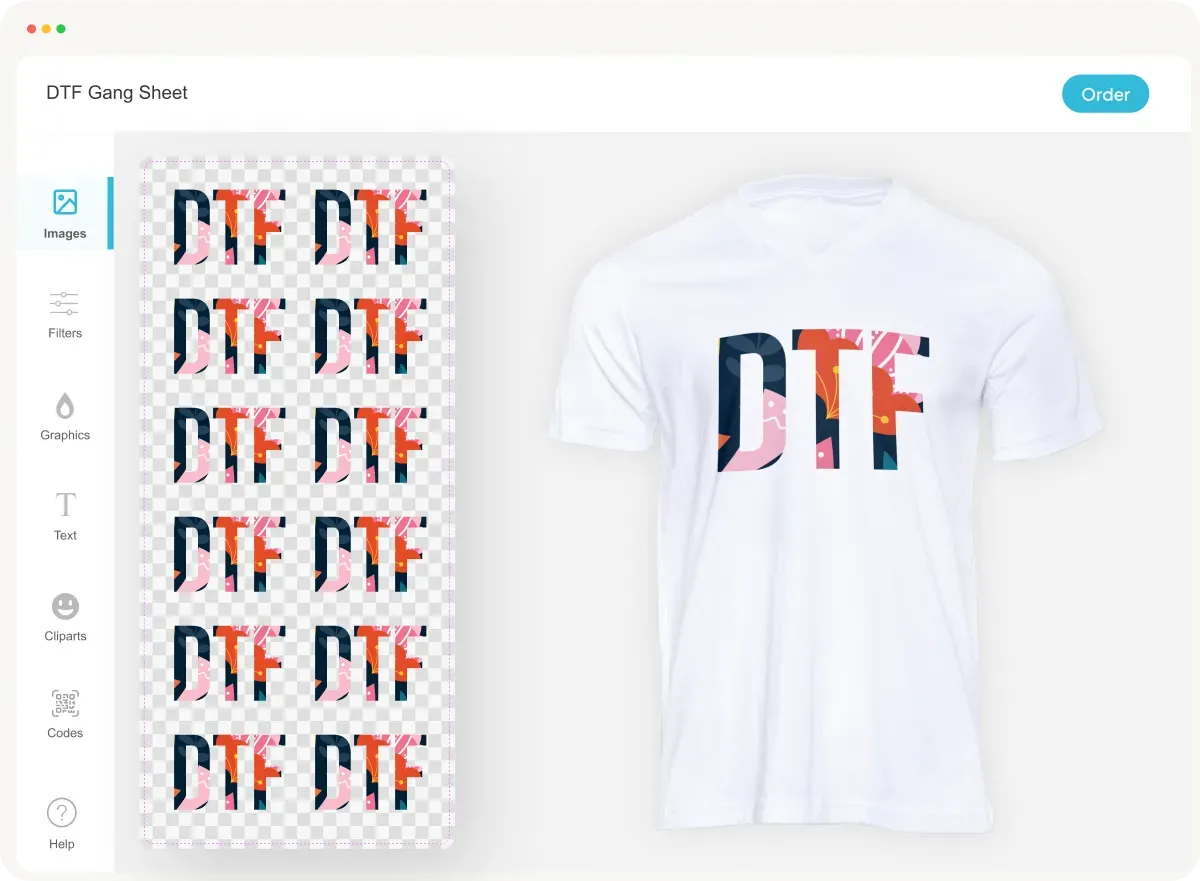

DTF gangsheet builder is at the heart of modern Direct-to-Fabric production, turning design ideas into precise print-ready sheets. This tool blends intuitive layout with advanced color control to ensure the DTF printing features you rely on translate faithfully from screen to fabric. With professional-grade gang sheets and a streamlined workflow, it helps you maximize material use and deliver consistent results. The software supports efficient gang sheet design software capabilities, batch processing, and reliable preflight checks. By aligning with your DTF production workflow, it reduces waste, speeds up turns, and elevates overall print quality for clients.

Beyond the literal term, this versatile tool acts as a layout optimizer for fabric printing projects, arranging artwork blocks for fast, accurate production. LSI-minded descriptions might refer to it as a DTF layout engine, gang sheet creator, or production-ready sheet designer, expanding how search engines connect related ideas. It integrates with the wider production pipeline, linking asset management, color profiling, and automated exports to reduce touchpoints and errors. Focusing on repeatability and cross-material compatibility, it highlights substrate awareness, ink profiles, and heat-press workflows as core considerations. Together these related terms help readers understand how a modern fabric-printing tool supports scalable operations while maintaining print fidelity.

DTF gangsheet builder: Elevating professional-grade gang sheets and the DTF production workflow

In Direct-to-Fabric (DTF) printing, the tool you choose defines the accuracy and consistency of every sheet. A DTF gangsheet builder acts as more than a design canvas; it embeds color management, ICC profile support, and calibration workflows directly into the gang sheet creation process. With such features, you can ensure color fidelity across fabrics, inks, and batches, reducing surprises from one print run to the next. It aligns with DTF printing features that matter for pro results, such as accurate previews and color path warnings that help prevent oversaturation or dull tones.

Robust preflight checks and substrate-aware guidance extend the builder’s reach beyond layout. It validates image resolution, color space, font embedding, and even detects conflicting layers before you hit print. Substrate profiling and ink-compatibility guidance help you select the right heat settings, adhesive, and curing times for cotton, polyester, blends, or specialty finishes. Coupled with automation and batch processing, this tool supports a scalable DTF production workflow, enabling you to reproduce proven layouts for multiple orders while maintaining pro-quality outcomes.

Gang sheet design software: Streamlined tooling for a robust DTF production workflow

Efficient gang sheet design software delivers intelligent layout capabilities—automatic tiling, bleed control, and safe margins that protect print integrity during transfer. The software can automatically place designs to minimize waste, rotate or reflow items to fit irregular shapes, and batch multiple artwork files into a single gang sheet template. This level of automation reduces manual trimming, speeds up production, and helps you maximize material usage while preserving color accuracy across fabrics.

Beyond layout, gang sheet design software should integrate with your DTF production workflow through batch processing, standardized naming, and export options aligned to your RIP and printer. When combined with strong preflight validation, you can catch issues early and export print-ready files that preserve color profiles. API hooks and integrations with inventory, order management, or MIS keep data synchronized, enabling a scalable operation that consistently delivers professional-grade gang sheets on tight deadlines.

Frequently Asked Questions

How does the DTF gangsheet builder improve color accuracy and layout efficiency within the DTF production workflow?

A DTF gangsheet builder bundles essential DTF printing features—such as ICC-based color management, intelligent color matching, and accurate previews—into a single tool. It also functions as gang sheet design software that automatically tiles designs, optimizes margins and bleeds, and supports rotations to maximize sheet usage. Together, this helps you produce professional-grade gang sheets with consistent color fidelity and faster turnaround in the DTF production workflow.

Why are robust preflight checks and substrate/ink compatibility features essential in a DTF gangsheet builder?

Robust preflight checks catch common issues (resolution, color space, fonts, and export formats) before printing, preventing misprints and waste. Substrate and ink compatibility awareness guides settings, adhesives, and curing times for different fabrics, reducing color shifts and durability problems. These features support reliable, print-ready gang sheets and a smoother DTF production workflow.

| Feature | Description | Key Benefits | Practical Notes |

|---|---|---|---|

| 1) Precise color management and calibration for pro-quality results | Color accuracy backbone for DTF projects, with ICC profile support, intelligent color matching, and built-in calibration workflows to ensure screen-to-fabric fidelity. | – Consistent color across batches and inks – Accurate previews reduce reprints and waste – Compatibility with Pantone references where applicable |

– Import and apply ICC profiles – Simulate fabrics under different lighting – Warn about oversaturation or dull tones during paths |

| 2) Flexible and intelligent gang sheet layout for maximum efficiency | Smart layout, tiling, spacing, and orientation with automatic placement to minimize waste while preserving print integrity. | – Optimized material usage reduces waste and costs – Faster turnarounds – Easy replication of proven layouts for repeat orders |

– Automatic tiling with bleed control – Rotation options for irregular shapes – Batch multiple designs into a single gang sheet – Consider margins, platen safety areas, and heat-press compatibility |

| 3) Robust preflight checks and file validation to prevent failures | Preflight validation catches common issues before production, verifying image resolution, color space, file formats, and font embedding with actionable feedback. | – Minimum DPI/resolution for full-sheet enlargement – Correct color space (CMYK vs RGB) and gray balance – Supported export formats and proper font embedding – Detection of conflicting layers or locked elements |

– Built-in preflight system to catch issues in busy shops before printing |

| 4) Substrate and ink compatibility awareness for durable results | Substrate profiling and ink-compatibility guidance to choose printer settings, adhesives, and curing times per material. | – Substrate presets for common fabrics with recommended heat-press times/temperatures – Ink compatibility guidance aligned with printer, ink, and finish – Warnings about ink bleeding or color shift with mitigation tips |

– Reduce trial-and-error cycles and preserve design appearance across fabrics |

| 5) Seamless production workflow and automation for scalability | Integration with the overall production workflow, featuring batch processing, queuing, naming conventions, and export automation for scalable operations. | – Batch processing across designs and sizes – Clear naming/archiving conventions – Ready-to-print export options aligned with RIP/printer settings – API hooks for inventory, order management, or MIS |

– Automation shifts manual tasks to design and QC focus; essential for fast-paced production |

Summary

DTF gangsheet builder is the cornerstone of a modern, production-ready workflow for garment printing. By prioritizing precise color management, intelligent layout, robust preflight checks, substrate- and ink-compatibility awareness, and seamless automation, you can streamline operations, reduce waste, and consistently deliver pro-quality gang sheets. For shops looking to elevate their DTF printing capabilities, invest in a DTF gangsheet builder that embraces these five must-have features to transform workflows from reactive to proactive, scalable, and reliably excellent.