DTF gangsheet builder: From Design to Dispatch Success

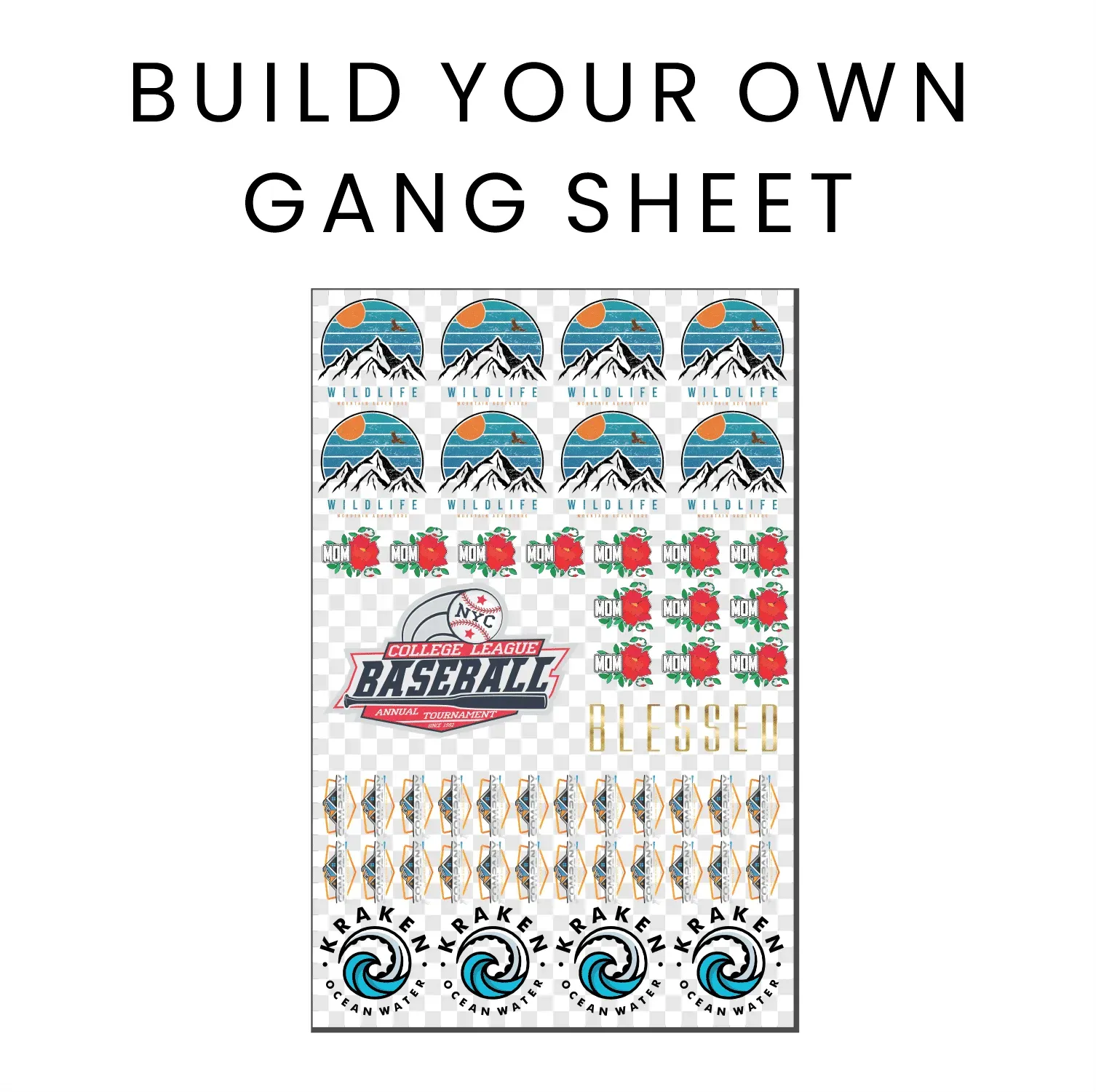

DTF gangsheet builder sits at the heart of modern transfer printing, turning a cluster of designs into a single, print-ready sheet. It streamlines the workflow by coordinating artwork, color management, and production steps across multiple items. This approach helps reduce setup time and material waste while maintaining vibrant color and clean edges. Teams can preview layouts, verify alignment, and ensure safe margins before any ink hits the film. With the right process, you can scale from small runs to larger batches without sacrificing quality.

Viewed through an LSI lens, the broader gangsheet workflow becomes a coordinated system for batching designs, color management, and streamlined production steps. Phrasing such as gangsheet design tips for DTF can be translated into practical guidance on template grids, safe margins, and color separation across multiple designs. When mapped to the DTF printing workflow, the focus shifts to asset management, consistent rip configurations, and reliable transfers. Guidance on how to create gang sheets for DTF can be supported by practical templates and documented workflows.

DTF gangsheet builder: From Design Prep to Dispatch

DTF gangsheet builder is the engine that consolidates many designs into one print-ready sheet. It maximizes each print run by arranging artwork efficiently, managing color intent, and coordinating prepress and production steps so garments such as T-shirts, hoodies, or accessories read clean and vibrant when transferred. This approach is central to the DTF gangsheet process and the wider DTF printing workflow.

This stage starts with thorough design prep and asset management: gathering artwork, fonts, color profiles, and reference materials; ensuring colors map to the printer’s CMYK space; maintaining high resolution (usually 300 dpi); and keeping editable RAW files for later tweaks. This is also where the question of how to create gang sheets for DTF comes into focus, answered by clean assets and consistent templates. Use DTF layout software to apply ICC profiles, lock fonts, and align everything to a predictable grid—an actionable application of gangsheet design tips for DTF.

Layout and workflow efficiency in the DTF gangsheet process

Layout planning forms the backbone of the DTF gangsheet process. Define sheet dimensions and margins, create a consistent grid (e.g., 4×6 for smaller designs or 2×3 for larger ones), manage spacing and bleed, and plan alignment to minimize color bleed and misregistration. A robust layout relies on DTF layout software features such as grid-based placement, scalable templates, and integrated color management to maximize sheet utilization.

Once the layout is locked, move into proofing and export. Perform soft proofs that simulate how colors will appear on the final transfer, run preflight checks, and export print-ready files with the correct ICC profile. The export is followed by RIP configuration and alignment with the DTF printing workflow to ensure ink channels, line weights, and transfer parameters stay consistent. Knowing how to create gang sheets for DTF becomes actionable here, as templates and automation reduce rework and improve reliability.

Frequently Asked Questions

What is a DTF gangsheet builder and how does it fit into the DTF printing workflow?

A DTF gangsheet builder is a workflow and set of tools that arranges multiple artwork files onto a single transfer sheet. Its goal is to maximize designs per sheet while preserving color accuracy, margins, bleed, and alignment. In practice it covers design prep, layout planning, proofing, export and RIP setup, the actual printing and curing, and final dispatch. Using a well-managed DTF gangsheet builder reduces setup time, minimizes waste, and scales production from small shops to mid-sized studios by delivering consistent, high-quality transfers across a run.

What are gangsheet design tips for DTF when using a DTF layout software, and how do you create gang sheets for DTF?

Key gangsheet design tips for DTF include planning a consistent grid, defining sheet dimensions and safe margins, incorporating bleed where needed, and maintaining color management with ICC profiles. Use a DTF layout software to align designs, maintain spacing, and prove prints before production. To create gang sheets for DTF, start with design prep, set up a repeatable grid in the software, run preflight checks, export a print-ready file with the correct color profile, configure the RIP for ink channels, and then print, transfer, cure, and dispatch as a single, repeatable DTF gangsheet process.

| Stage | Key Points |

|---|---|

| 1) Design prep and asset management |

|

| 2) Layout planning: designing a practical gangsheet |

|

| 3) Proofing and preflight checks |

|

| 4) Export, rip, and print-ready preparation |

|

| 5) The actual printing, transfer, and curing process |

|

| 6) Packaging, labeling, and dispatch |

|

| 7) Troubleshooting and optimization tips |

|

| 8) Tools and software: what to look for in a DTF layout software |

|

Summary

DTF gangsheet builder is a powerful framework that streamlines the journey from design to dispatch in apparel printing. This structured approach aligns artwork, layout, proofing, printing, curing, and dispatch into a repeatable workflow, reducing setup time, waste, and misprints while boosting throughput. For any shop—from a small bench operation to a growing studio—the DTF gangsheet builder can dramatically improve margins, turnaround times, and customer satisfaction. To maximize results, audit your current gangsheet workflow, identify bottlenecks, and invest in the right layout software and checks at every stage. By standardizing processes, the DTF gangsheet builder becomes a competitive advantage that delivers consistent, high-quality transfers from concept to customer.