DTF transfers: A Beginner’s Guide to Direct-to-Film Printing

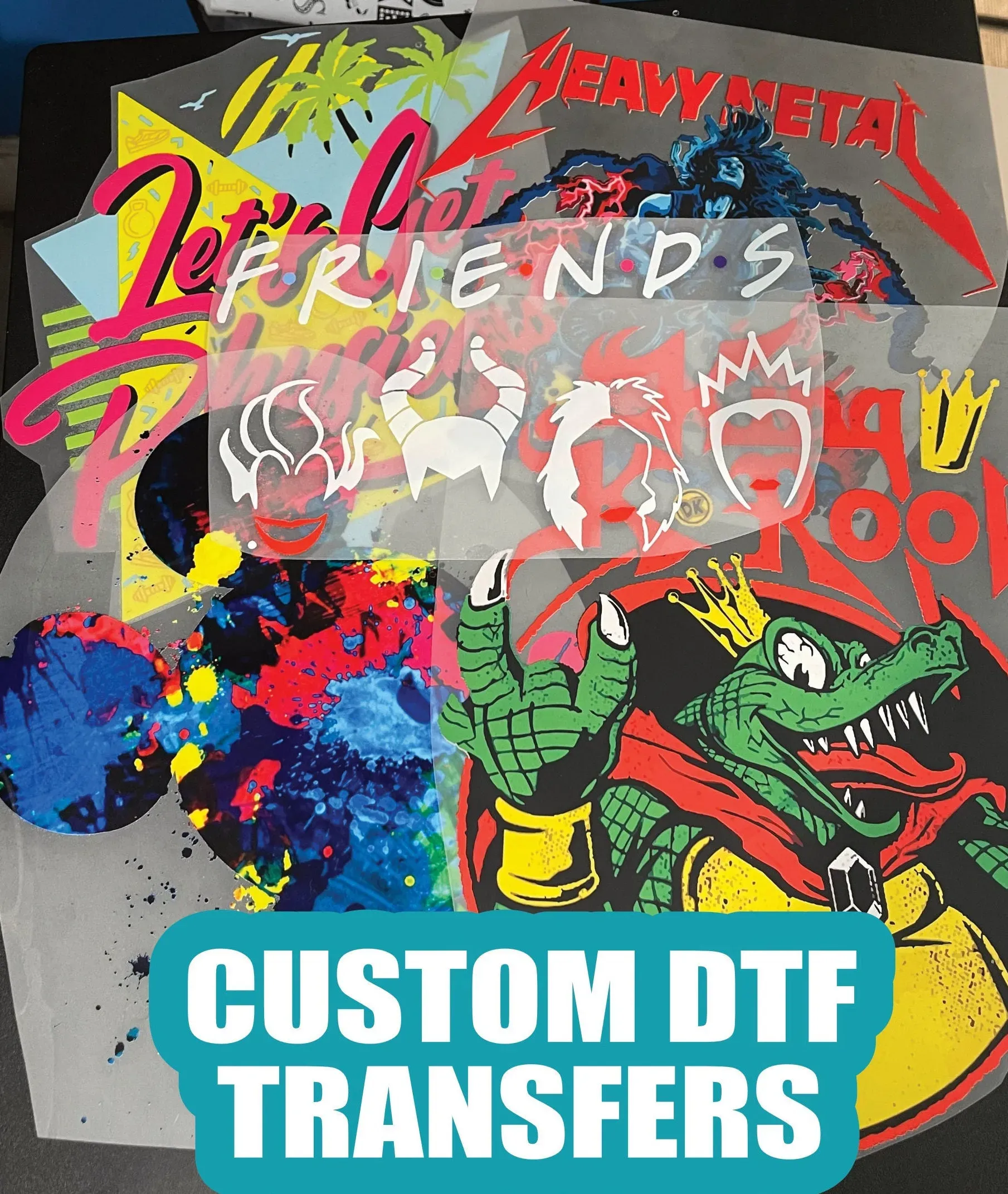

DTF transfers have quickly become one of the most accessible methods for producing durable, high-quality prints on fabric. Direct-to-Film printing lets designers create vibrant designs and apply them to a wide range of fabrics. If you’re exploring DTF printing for beginners, this Direct-to-Film printing guide covers the essentials—from technology to the DTF transfer steps. This approach offers flexibility, lower upfront costs, and a clear comparison of DTF vs screen printing. By understanding the workflow and choosing the right DTF materials and supplies, you can produce reliable, high-quality results.

In other terms, this film-based transfer method uses a printed sheet that is later fused to fabric via heat. You might hear it described as a print-on-film workflow or an adhered-graphic technique for apparel. From an LSI perspective, terms like film-backed imagery, heat-applied graphics on textiles, and digital transfer to fabric help connect related topics. Compared with DTG and screen printing, the film-based path emphasizes compatibility across fabrics, easy color control, and efficient prep. Ultimately, learning the terminology through guides such as DTF printing for beginners and Direct-to-Film printing guide will empower your project choices.

DTF Transfers: A Descriptive Guide for Beginners

DTF transfers have emerged as one of the most accessible methods for getting durable, high-quality prints on fabric. In this Descriptive guide to DTF printing for beginners, you’ll explore how Direct-to-Film printing works, why it’s appealing for small businesses and crafters, and how a typical workflow translates into reliable results. By understanding the basics of DTF transfers, you’ll see how this approach combines strong image fidelity with a relatively forgiving setup compared to other methods, making it a practical option for beginners.

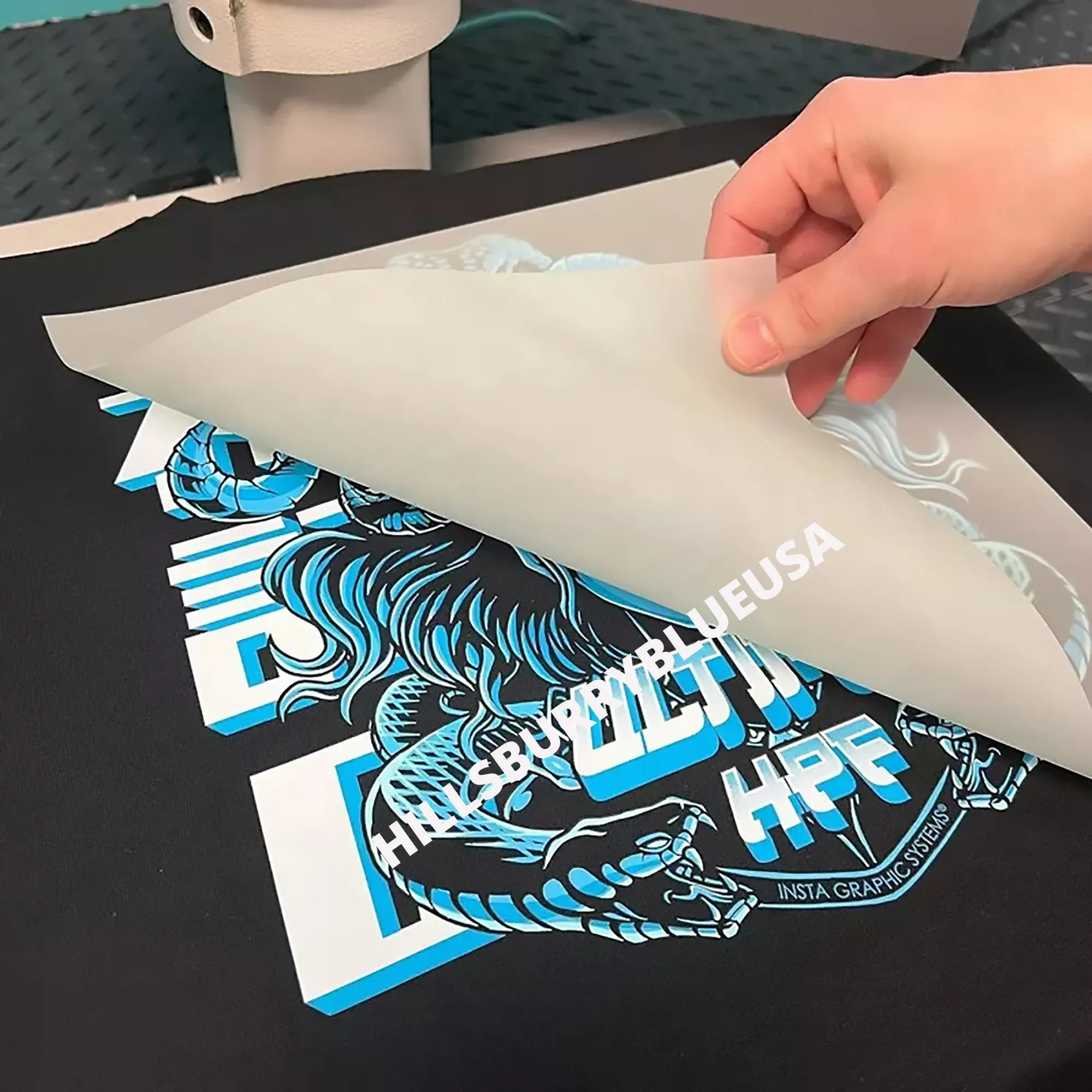

DTF transfer steps form the backbone of a repeatable process, from preparing a design to final transfer onto fabric. The core steps—design optimization, printing on DTF film, powder application, curing, alignment, and heat-press transfer—are designed to build confidence and minimize errors with each run. This section aligns with the Direct-to-Film printing guide concept, emphasizing how white ink bases enable vibrant colors on dark fabrics and how a consistent workflow helps produce professional-looking results. As you gain experience, you’ll also learn how to troubleshoot color accuracy, powder adhesion, and peeling in ways that support steady improvement.

DTF Printing: Materials, Steps, and Comparisons to Other Methods

Choosing the right DTF materials and supplies is foundational to a successful print. The discussion here mirrors the essentials of a practical DTF materials and supplies checklist: a printer capable of white ink, DTF film, CMYK and white inks, color management software, adhesive powder, a heat press, and curing tools. Understanding these components through a lens like the DTF printing for beginners guide helps new printers plan purchases, set up a practical workspace, and build a scalable workflow that remains affordable while delivering consistent results.

Understanding how DTF transfers compare to other methods—DTF vs screen printing, DTG, or sublimation—helps you choose the right approach for each project. The Direct-to-Film printing guide emphasizes the strengths of DTF transfers, such as versatile fabric compatibility and relatively straightforward maintenance, while acknowledging trade-offs with different processes. By studying DTF transfer steps and best practices, you can tailor your approach to your target substrates, production volume, and budget, ensuring you’re making informed decisions rather than relying on a single method for all applications.

Frequently Asked Questions

What are the DTF transfer steps for beginners in DTF printing?

DTF transfer steps for beginners start with preparing a print-ready design that accounts for the white underbase on dark fabrics. Then print the design on DTF film using CMYK plus white, and apply adhesive powder while the ink is still tacky. Cure the powder to fix it, align the bonded film on the fabric, and transfer with a heat press at the recommended temperature, time, and pressure. After cooling, peel the film and complete any post-press steps. This approach mirrors standard Direct-to-Film printing guide steps and relies on essential DTF materials and supplies to ensure consistent results.

DTF transfers vs screen printing: which is better for beginners in DTF printing?

DTF transfers often offer lower setup costs, easier maintenance, and better fabric compatibility than screen printing, making them popular for beginners in DTF printing. In the DTF vs screen printing comparison, you’ll typically see a simpler, more forgiving workflow with strong durability on a variety of fabrics. To start strong, invest in quality DTF materials and supplies and build a repeatable workflow with proper heat press settings. For high-volume production, screen printing can be cost-effective, but for most beginners, DTF printing for beginners provides a faster path to reliable, high-quality results.

| Topic | Key Points | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| What are DTF transfers? | DTF transfers involve printing a design onto a special film, applying adhesive powder, curing the powder, and transferring the design to fabric with a heat press. They are versatile, generally lower in setup costs, and work on a broad range of fabrics (cotton, blends, and some synthetics).’}]},{ | Why choose Direct-to-Film printing? | DTF enables vibrant, full-color images with smooth gradients and sharp edges; offers flexible substrate choices and straightforward workflows; provides durable transfers with good wash fastness when cured; opens opportunities for custom apparel, team merchandise, and personalized gifts. | Materials and equipment (DTF materials and supplies) | Core components: DTF printer with white ink capability, DTF film and release-coated sheets, CMYK inks plus white ink, color management/software, DTF powder, heat press, curing tools. Optional: curing oven or rack. Start with a basic kit (printer with white ink, compatible film, pre-mixed powders) and expand over time. | The DTF transfer workflow (step-by-step) | 1) Prepare design (high resolution, proper color separations; white underbase for dark fabrics). 2) Print on DTF film with CMYK + white. 3) Apply adhesive powder while film is tacky. 4) Cure the powder. 5) Align and transfer to fabric with heat press. 6) Peel and finish (hot or cold peel per material guidelines). | Common troubleshooting tips | Color accuracy: adjust white underbase and RIP color profiles. White ink opacity: ensure strong white underbase and proper curing. Powder adhesion: apply powder evenly and cure uniformly. Peeling issues: verify heat time, temperature, pressure, and fabric bonding requirements. | Best practices for beginners (DTF printing for beginners) | Use quality materials; test on swatches; maintain equipment; calibrate color and layout; document settings and results to streamline future projects. | DTF transfers vs other methods (DTF vs DTG vs sublimation vs screen) | DTF transfers often have lower setup costs, easier maintenance, and broad fabric compatibility compared to DTG and sublimation. Sublimation excels on polyester, while DTF works on a wider fabric range. Screen printing can be cost-effective at high volumes but requires more setup and screens. | Maintenance and care for your DTF workflow | Regular maintenance includes cleaning printer heads, rinsing/drying film tools, storing powders/films in a cool, dry place, and periodically calibrating the heat press for consistent results. |

| Conclusion | DTF transfers offer a practical, scalable way to produce vibrant, durable prints on a broad range of fabrics. By understanding the basics of direct-to-film printing and following a repeatable workflow, you can build confidence as a printer and expand your offerings—from personalized tees to small-batch merchandise. With quality materials, consistent processes, and careful documentation, DTF transfers can achieve reliable, high-quality results that satisfy clients and inspire creativity. |

Summary

DTF transfers are a practical, scalable way to produce vibrant, durable prints on a broad range of fabrics. By understanding the basics of direct-to-film printing and following a repeatable workflow, you can build confidence as a printer and expand your offerings—from personalized tees to small-batch merchandise. With quality materials and careful calibration, DTF transfers deliver consistent results and open opportunities for designers and crafters to grow their business.