DIY DTF Transfers: Best Supplies for Stunning Results

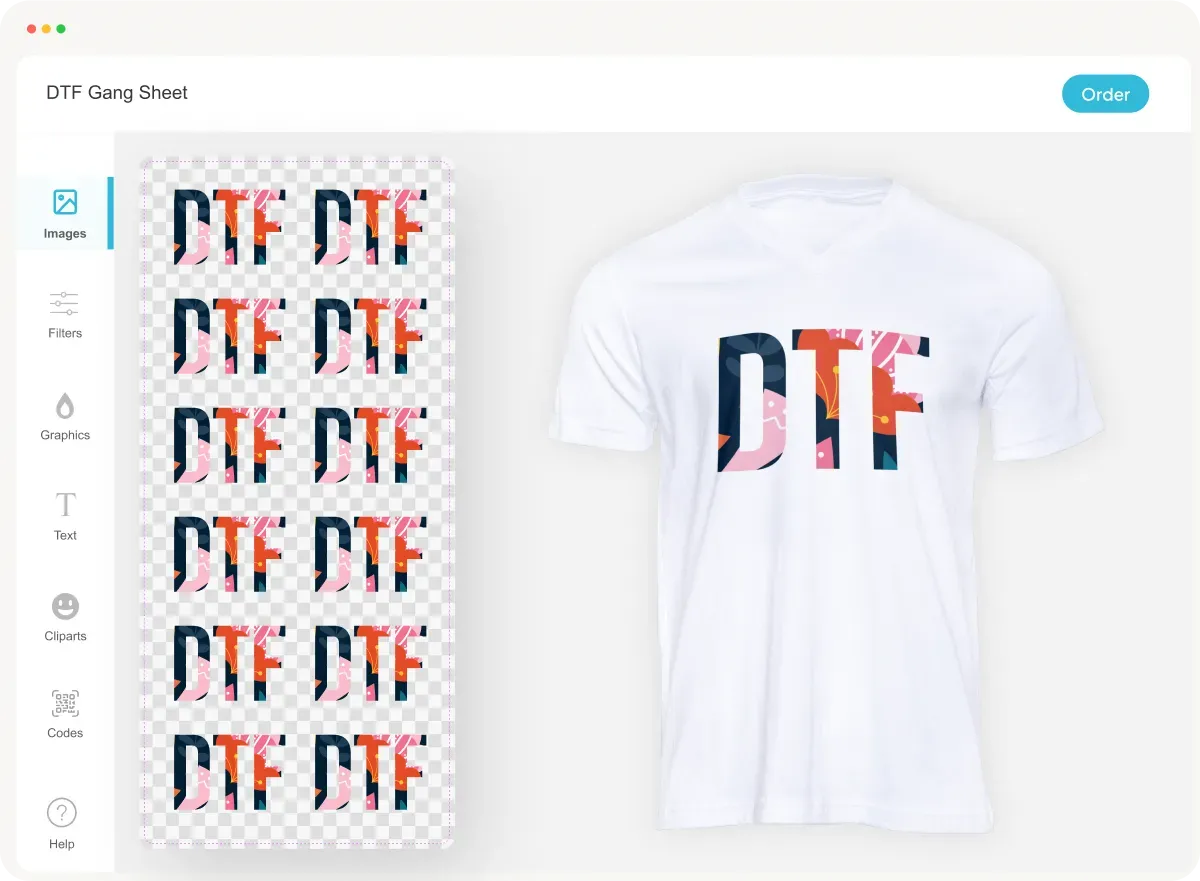

DIY DTF Transfers are revolutionizing the way we approach custom fabric printing, allowing creators to bring their designs to life with remarkable clarity and color. With the rise in popularity of DTF printing, it’s now more accessible than ever for hobbyists and small businesses to produce stunning transfers at home. This innovative method not only provides durable results on various materials but also opens up a world of possibilities for personalized apparel and merchandise. As we delve into the essentials, we’ll help you discover the best supplies for DTF, from high-quality DTF transfer film to the optimal heat press for DTF projects. Join us on this exciting journey to master DIY DTF transfers and elevate your crafting game!

When we talk about direct-to-film transfers, we refer to a cutting-edge technique in the realm of fabric print methods that allows for high-resolution designs with exceptional color fidelity. This approach, often seen as an alternative to screen printing, utilizes specialized films and heat application to create intricate images on various fabric types. Enthusiasts often seek out the best materials—including unique inks and compatible printers—to harness the power of custom fabric printing. Whether you’re an aspiring entrepreneur or a DIY crafter, exploring the ins and outs of DTF techniques can unleash your creative potential and lead to unique, market-ready products.

What is DTF Printing?

Direct to Film (DTF) printing is an innovative method of transferring ink from a specially designed film directly onto fabric using heat and pressure. This technique has gained popularity for its versatility, enabling DIY enthusiasts and businesses to produce vibrant designs on a variety of fabric types including cotton, polyester, and blends. The DTF process allows for intricate designs, making it particularly appealing for custom fabric printing, whether for apparel, bags, or other textile products.

One of the primary advantages of DTF printing lies in its efficiency and the quality of the final product. Unlike traditional methods, DTF allows for the production of clear, detailed graphics that resist fading, peeling, or cracking over time. This durability ensures that garments made using DTF transfers will withstand everyday wear and washing, which is a significant selling point for those venturing into the custom merchandise market.

Essential DTF Supplies for Quality Results

To achieve stunning results in your DIY DTF projects, it’s crucial to gather the right supplies. A high-quality DTF printer is at the forefront of this setup, as it directly influences the print quality and the vibrancy of colors. Brands like Epson, particularly their EcoTank series, are commonly recommended due to their compatibility with DTF inks and their ability to provide cost-effective printing options.

Additionally, DTF transfer film is another vital component. This film must be specifically designed for DTF applications, ensuring it has the right coating for ink adhesion. Choosing well-reviewed brands like TTD or A4 Aqua can vastly improve your transfer outcomes by enhancing the smoothness of the application process, ultimately contributing to a more professional finish on your custom fabric pieces.

The Importance of Heat Press in DTF Transfers

A reliable heat press is of utmost importance when it comes to DTF transfers. This equipment applies the necessary heat and pressure required to transfer the ink from the film to the fabric effectively. Selecting a heat press with adjustable temperature and pressure settings allows you to customize the transfer process for various materials, ensuring the best adhesion and durability for your designs.

Models like Hotronix heat presses are highly regarded in the crafting community for their user-friendly features and consistent performance. Using a quality heat press minimizes the risk of errors during the transfer, such as uneven heat distribution, which can compromise the quality of the print. Overall, investing in a top-notch heat press is a crucial step towards achieving professional-grade results in your DIY DTF projects.

Choosing the Right DTF Inks

Choosing the right DTF inks is essential for anyone looking to produce high-quality prints. These inks are specifically formulated to enhance adhesion to transfer films and the resulting fabric, ensuring that the colors are vibrant and long-lasting. It’s advisable to opt for proprietary DTF inks compatible with your printer to avoid problems such as clogged nozzles or color inconsistencies.

Many crafters in the DTF community recommend inks that cater to both soft-hand feel and bold color saturation, allowing for stunning, eye-catching designs on fabric. Quality inks can significantly influence your end product; hence, researching the best options available through reputable suppliers ensures that your DIY projects yield incredible results.

Tips for Successful DTF Transfers

To maximize your success with DIY DTF transfers, experimenting with different heat and pressure settings is essential. Ideal temperatures may vary based on the type of fabric used, so it’s important to conduct tests before fully committing to a project. This experimentation helps determine what works best for your designs, ensuring they adhere properly to the fabric.

In addition, proper handling and storage of DTF transfer films and other supplies are crucial for maintaining their quality. Avoid exposing them to high humidity or direct sunlight, which can degrade their performance. Regular maintenance of your heat press and printer is also key; keeping equipment clean can help reduce the occurrence of mishaps during the transfer process, leading to more successful outcomes.

Recent Trends in the DIY DTF Community

The DIY DTF community is witnessing exciting trends that focus on innovation and excellence in printing. Creators are increasingly sharing their insights on social media platforms and blogs, providing tips and tutorials to refine techniques and improve print quality. Many crafters are exploring unique methods for film preparation and proper application techniques to enhance the durability and visual appeal of their DTF projects.

Online resources have become invaluable, featuring step-by-step guides that cater to both beginners and seasoned professionals alike. This shared knowledge empowers many to push the boundaries of design, enabling them to create not only stunning apparel but also a wide range of customized products. Staying informed on these trends can significantly influence your approach to DIY DTF transfers, as you adapt to best practices established by the crafting community.

Frequently Asked Questions

What are the best supplies for DIY DTF Transfers?

To achieve the best results in DIY DTF transfers, you will need several key supplies: a DTF printer (like the Epson EcoTank), DTF transfer film (such as TTD or A4 Aqua), adhesive powder (like Hydra Transfer), a reliable heat press (Hotronix is a recommended brand), and high-quality DTF inks specific to your printer. Investing in these essential supplies will help you create stunning and durable custom fabric prints.

How does DTF printing work for creating custom fabric printing?

DTF printing involves printing designs onto a special film using a DTF printer, followed by applying a heat-activated adhesive powder. The design is then heat-pressed onto the fabric, allowing the ink to transfer from the film, resulting in vibrant, long-lasting prints on various materials like cotton and polyester. Understanding this process is crucial for successful DIY DTF transfers.

What properties should I look for in DTF transfer film?

When selecting DTF transfer film, ensure it has a specialized coating designed for ink adhesion. High-quality transfer films, such as TTD or A4 Aqua, are recommended for their excellent performance. Proper film quality is essential for achieving crisp designs and ensuring that the prints adhere effectively to the fabric during the heat transfer process.

What type of heat press is best for DIY DTF transfers?

For DIY DTF transfers, a heat press with adjustable temperature and pressure settings is ideal. Hotronix heat presses are often recommended due to their reliability and effectiveness in achieving optimal transfer results. Choosing a press that suits your fabric type and design complexity will enhance the overall quality of your custom fabric printing projects.

Why is adhesive powder important in DIY DTF transfers?

Adhesive powder is crucial in DIY DTF transfers as it merges with the wet ink to solidify the design’s adherence to fabric. Using a high-quality, heat-activated adhesive powder ensures that your prints remain vivid and long-lasting on various substrates. Look for powders that are easy to apply and specifically formulated for DTF packaging to get the best results.

What are some common mistakes to avoid in DIY DTF transfers?

Common mistakes in DIY DTF transfers include using the wrong type of film or inks, improper heat press settings, and neglecting to maintain equipment. Ensure you use supplies designed for DTF printing and regularly clean your printer and heat press. Additionally, always test heat and pressure settings on scrap fabric before proceeding with your final project to avoid errors.

| Key Supplies for DIY DTF Transfers | Description | Purpose/Importance | |

|---|---|---|---|

| DTF Printer | Essential for producing the prints, with Epson and Brother being popular choices. | ||

| DTF Transfer Film | Specially coated film necessary for ink adhesion and a smooth application. | ||

| Adhesive Powder | Powder that ensures the design adheres to the fabric when heated. | ||

| Heat Press | Used to transfer the design from the film to the fabric under heat and pressure. | ||

| DTF Inks | Specialized inks formulated to work with DTF processes for vibrant results. | ||

Summary

DIY DTF Transfers present an exciting opportunity for anyone looking to create vibrant and durable prints on fabrics. By understanding the key supplies needed—such as a quality DTF printer, specialized transfer film, adhesive powder, a reliable heat press, and high-quality DTF inks—you can unlock stunning results in your projects. This innovative printing technique allows for detailed and colorful designs, making it ideal for personalized apparel and merchandise. As you embark on your journey in DIY DTF Transfers, invest wisely in your supplies and follow best practices to ensure your creations stand out in a competitive market.