DTF gangsheet builder: Cost-Saving Secrets to Cut Waste

DTF gangsheet builder has emerged as a transformative solution for printers who want to maximize substrate usage, cut material waste, and improve consistency across runs right from the first print. By automatically tiling designs with smart spacing and bleed, it drives DTF waste reduction and helps teams squeeze more designs onto every sheet. In addition to layout automation, the tool enhances DTF printing efficiency by reducing misprints and streamlining color separation. Shop owners see garment printing cost savings when production planning is optimized and ink usage is managed across batches. A disciplined approach to DTF workflow optimization, supported by templates and clear responsibilities, turns the gangsheet process into a repeatable competitive advantage.

In practice, many teams call this function a layout optimizer, a gangsheet automation tool, or a prepress workflow accelerator that coordinates placement, color channels, and trimming tolerances. LSI-friendly language favors phrases like sheet tiling strategy, automated layout generation, and batch-friendly production planning to capture related search terms. The result is faster throughput, fewer errors at RIP processing, and more predictable color output across garments. To stay efficient, invest in standard templates for common shirt types, maintain consistent color profiles, and monitor waste metrics. For ongoing improvement, follow DTF gangsheet builder best practices and iterate on templates, color rules, and batching to sustain cost savings. This approach also aligns with lean manufacturing principles, reducing waiting time between steps and minimizing work-in-progress. In short, adopting a robust DTF gangsheet strategy translates into measurable productivity gains and resilient margins. Organizations that formalize the gangsheet workflow report smoother audits, easier training, and better traceability of prints. The bottom line is stronger profitability through reduced waste, faster shipping, and repeatable quality. As you experiment across batches, you’ll uncover additional savings that compound over time. Investing in training ensures that the whole team leverages the system effectively. With ongoing optimization, the benefits scale as you add more designs and orders.

DTF Gangsheet Builder: Maximize Substrate Use, Reduce Waste, and Realize Garment Printing Cost Savings

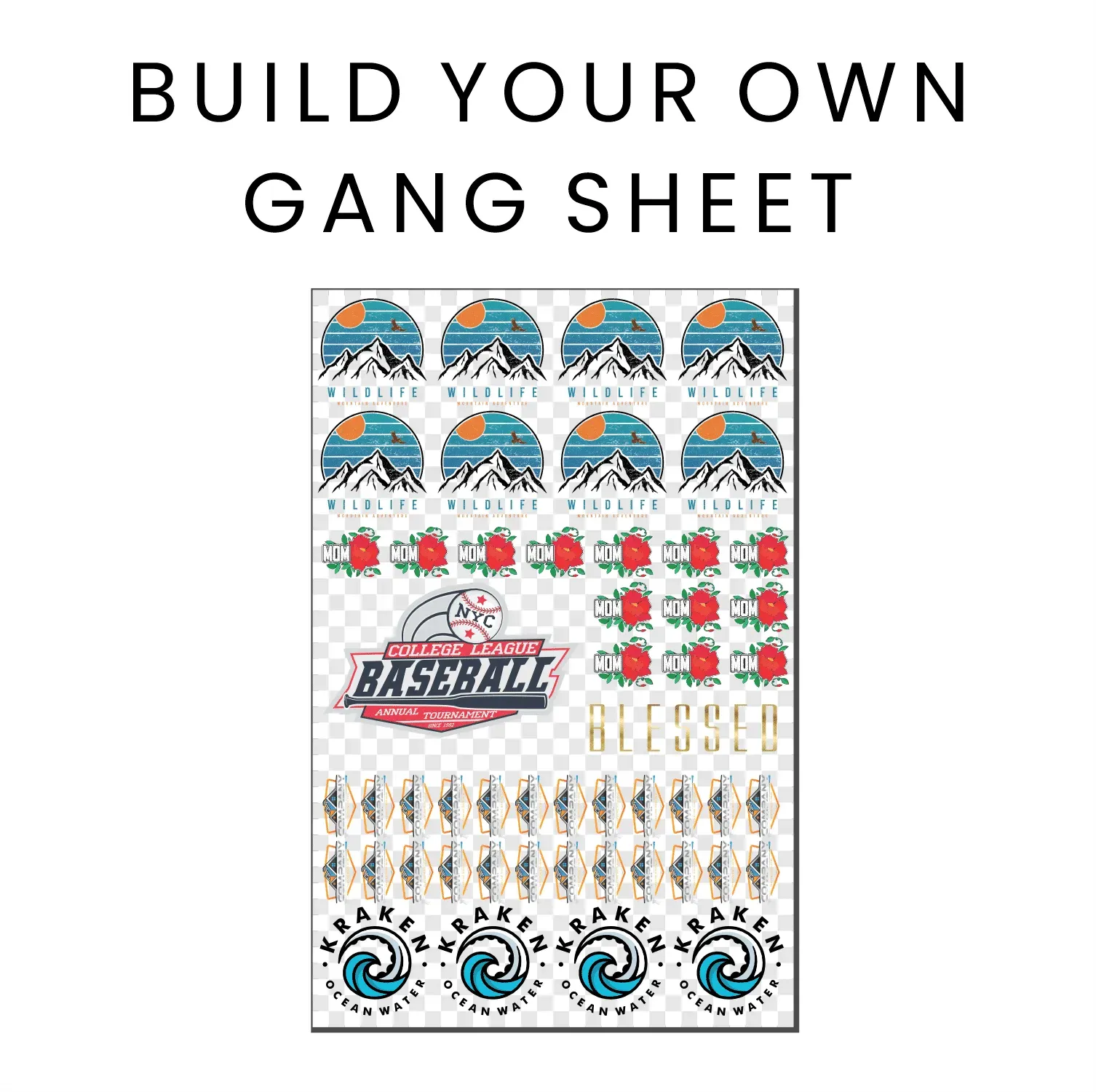

The DTF gangsheet builder automates the tiling of multiple designs on a single print sheet with optimal spacing, margins, and bleed. By minimizing wasted blank space and preventing overlapping artwork, this approach directly supports DTF waste reduction and translates into tangible garment printing cost savings. With smarter layout, you also improve substrate yield per job, which lowers material costs without compromising print quality or color integrity.

Beyond material savings, a well-designed gangsheet reduces misprints and reworks by providing predictable placement and cleaner color separations. This enhances DTF printing efficiency across orders of varying sizes and contributes to a smoother prepress-to-press workflow. When combined with effective color management and batch optimization, the gangsheet strategy becomes a strategic asset for cost-conscious shops seeking measurable improvements in throughput and margins.

DTF Workflow Optimization: Best Practices to Boost DTF Printing Efficiency with a Smarter Gangsheet Strategy

Adopting DTF gangsheet builder best practices starts with cross-functional alignment between design, prepress, and production teams. Standardize file formats, color profiles, and template usage so layouts translate consistently from concept to print. This alignment supports DTF workflow optimization by reducing handoffs, errors, and setup time, while preserving color accuracy and detail across large and small runs.

To maximize impact, implement repeatable templates for common garment types and print placements, and leverage order batching to group similar jobs on a single sheet. Track metrics such as substrate waste, ink consumption, and cycle time to quantify DTF waste reduction and garment printing cost savings. With disciplined monitoring and ongoing refinement, shops can realize sustained DTF printing efficiency gains and a faster, more predictable production cadence.

Frequently Asked Questions

How does a DTF gangsheet builder drive DTF waste reduction and garment printing cost savings?

A DTF gangsheet builder automatically tiles multiple designs on a single sheet with optimized spacing and color separation, which minimizes blank space and misprints. This reduces substrate waste and supports DTF waste reduction, contributing to garment printing cost savings and improving DTF printing efficiency. By aligning prepress, RIP processing, and printer operations, it also supports DTF workflow optimization and faster turnarounds.

What are the DTF gangsheet builder best practices for maximizing DTF workflow optimization?

These DTF gangsheet builder best practices help maximize DTF workflow optimization. Start with a baseline waste and cost audit, map your typical orders, and create standard templates for common layouts. Use automatic tiling, smart spacing, and color channel optimization, and ensure compatibility with your RIP and printer. Batch similar jobs to reduce setup time, generate proofs before production, and continually measure waste, ink usage, and cycle time to drive garment printing cost savings.

| Theme | Key Points |

|---|---|

| What is a DTF Gangsheet Builder and Why It Matters | Automatically arranges multiple designs on a single sheet with optimal spacing, color separation, and orientation to minimize blank space, prevent overlaps, and reduce misprints, delivering higher efficiency and cost savings. |

| The Waste Problem in DTF Printing | Substrate waste from inefficient layouts and trimming; misprint waste from color misregistration or ink bleed. Both raise cost per shirt and extend lead times. |

| Cost-Saving Essentials: How a DTF Gangsheet Builder Helps | Maximizes substrate yield; reduces reprints and misprints; streamlines color management; improves workflow optimization; enables better order batching. |

| Key Features to Look For in a DTF Gangsheet Builder | Automatic tiling and optimization; smart spacing and bleed handling; color channel optimization; compatibility with your RIP/printer; design-aware templates; order batching; export-ready color profiles. |

| Implementing a DTF Gangsheet Strategy: Step-by-Step | Audit waste and costs; map typical orders; create standard templates; build optimized layouts; prepress proofs; run and monitor; iterate and improve. |

| Case Study: A Small Shop’s Transformation | A mid-sized shop reduces substrate waste, reprints, and cycle time through a robust gangsheet workflow, achieving significant cost savings and faster delivery. |

| Best Practices for Maximum Cost Savings and Efficiency | Align design/prepress teams; optimize file formats and color profiles; prioritize design efficiency; leverage leftovers; monitor performance; invest in training. |

| Common Pitfalls to Avoid | Over-optimizing for sheet density at the expense of print quality; ignoring printer/RIP limitations; underestimating setup time for new templates. |

| The Bottom Line: A DTF Gangsheet Builder Is a Strategic Asset | It directly addresses waste, improves efficiency, and boosts garment printing cost savings through smarter layout, color management, and workflow optimization. |