DTF GangSheet Builder: From Concept to Cut, Pro Tips

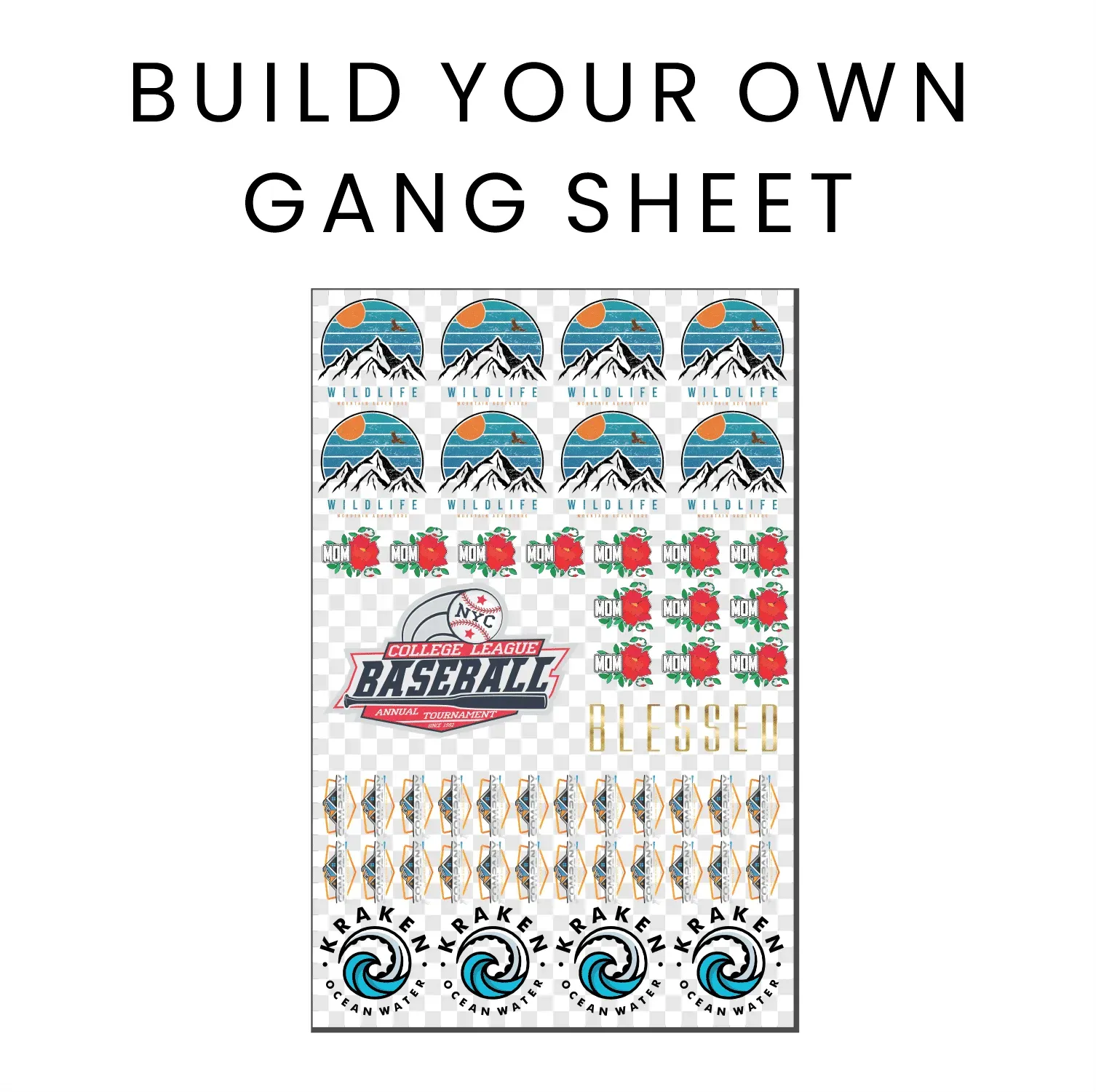

DTF GangSheet Builder turns a creative concept into production-ready prints by consolidating multiple designs onto a single sheet. It helps optimize material usage and streamline the DTF sheet layout so you can scale from concept to garment with confidence. Practical DTF gang sheet design tips keep alignment, color control, and space utilization tight across every block. In this guide, you’ll learn how careful planning reduces rework and improves transfer outcomes. You’ll gain actionable tips and best practices that boost efficiency and output quality, helping you deliver consistent results.

This section presents the topic using alternative terms that align with latent semantic indexing, focusing on group printing for textiles. Think of bundling multiple art files onto one production sheet for heat-transfer applications, with a clear grid, margins, and reference marks. The approach connects creative design with manufacturing steps by emphasizing placement, colors, and trimming readiness ahead of a press. By using related terms such as multi-design sheet planning, transfer-ready layouts, and precision trimming, the content remains discoverable through semantic relationships.

DTF GangSheet Builder: From Concept to Cut with Optimized DTF Sheet Layout and Design Tips

Turning a creative concept into a production-ready print starts with a smart gang sheet strategy. The DTF GangSheet Builder consolidates multiple designs onto a single sheet, optimizing material usage and aligning artwork with production realities. By applying DTF gang sheet design tips and a robust DTF sheet layout, you can scale small runs, reduce waste, and maintain consistent color and alignment across garments.

From concept to cut, establish a grid, define margins, and set spacing to ensure clean edges and predictable transfers. This discipline aligns with the broader DTF printing workflow, including color management, printer calibration, and proper curing, helping you avoid misalignment and ensure reliable results across the entire gang sheet.

Achieving Precision: DTF Printing Workflow, Cutting Accuracy, and Transfer Tips for High-Quality Gang Sheets

Precision starts with a disciplined DTF printing workflow and a reliable DTF sheet layout. Calibrating the printer, selecting the right media, and validating ink properties set the stage for consistent color and sharp edges across all designs on a gang sheet. When you translate print to cut, every millimeter counts, and that’s where DTF cutting accuracy becomes critical—good prep reduces misalignment and keeps blocks aligned.

Leverage practical DTF transfer tips during the final stage: preheat the garment surface, apply even pressure, and maintain a steady duration to ensure complete adhesion at design boundaries. A repeatable transfer process, paired with precise cutting and thoughtful layout, delivers reliable results across batches and helps you scale production without compromising quality.

Frequently Asked Questions

What is a DTF GangSheet Builder and how does it streamline the DTF printing workflow and DTF sheet layout?

DTF GangSheet Builder is a repeatable workflow that groups multiple designs on one sheet to maximize material use and speed production. It provides a grid-based DTF sheet layout with margins and alignment markers, linking concept to cut through a structured DTF printing workflow. Practically, you define designs, set up the grid, place assets with even spacing, prepare print-ready files, calibrate the printer, test print, and then cut. This approach reduces waste, improves color consistency, and shortens cycle times.

What are the key DTF gang sheet design tips to improve DTF cutting accuracy and ensure clean transfers?

Key DTF gang sheet design tips to improve DTF cutting accuracy and transfers include maintaining a consistent grid, margins, and alignment markers across all blocks, and labeling each design for production clarity. Ensure even spacing between designs and proper bleed to prevent crowding or white edges, and manage color profiles to keep color fidelity on the sheet. Run a test print to verify alignment, then use a thorough post-print inspection to catch any misprints. For transfers, follow DTF transfer tips: preheat the garment, apply even pressure and duration, and inspect the final result for edge definition and color fidelity.

| Aspect | Key Points |

|---|---|

| What is a DTF GangSheet and Why It Matters | – DTF stands for direct-to-film; a gang sheet is a large print containing multiple designs on one sheet. – Advantages: maximize printer throughput, reduce material waste, shorten production cycles. – With a well-executed DTF sheet layout, you can scale up small orders and experiment with new designs without sacrificing accuracy. |

| Core Idea of the DTF GangSheet Builder | – Provides a repeatable framework for planning, laying out, printing, and cutting multiple designs on a single sheet. – Bridges artistic concept to tangible product, aligning creative intent with production realities. – Becomes faster, more predictable, and easier to scale as you adopt this approach. |

| Key Benefits | – Improved material efficiency: fewer blank areas mean less waste. – Consistent color and alignment: reduces misalignment during transfer and cutting. – Faster production cycles: pre-planned layouts speed prepress and print stages. – Better quality control: structured workflow supports repeatable results across orders. |

| Section 1: Concept and Design Alignment | – Start with a clear design brief: list designs, target garment colors, sizes, quantities. – Gather design assets and ensure print-readiness: vector files when possible; high-res raster with proper bleed. – Consider color management: confirm color space, printer capabilities, ink properties. – Establish a grid system: define how many designs fit, orientation, margins. This becomes the backbone for layout. |

| Section 2: From Concept to Cut — Step-by-Step Workflow | 1) Create the gang sheet layout: use layout software, respect margins, safe zones, alignment markers; ensure even spacing to avoid bleed; label blocks for production reference. |

| 2) Prepare artwork for printing: convert to required color profiles/resolutions; vector for scaling; raster at 300 dpi+. Add bleed where necessary; add registration/boss marks if needed. | |

| 3) Validate the file and export settings: check layers, color management, export formats; save master + production-ready file; proof layout against sheet dimensions. | |

| 4) Printing workflow (DTF printing workflow): calibrate printer for consistent color; test print a small section; monitor temperature, humidity, ink usage. | |

| 5) Post-print inspection and cutting readiness (DTF cutting accuracy): allow film to dry/cure; check for smudges; ensure sheet is flat; verify blade settings, pressure, speed. | |

| 6) Transfer and testing (DTF transfer tips): preheat garment; apply even pressure and duration; inspect for color fidelity and edge definition; check for ghosting. | |

| Section 3: Quality Control and Troubleshooting | – Cutting accuracy is key: recalibrate cutter, verify layout and alignment markers. – Bleed and edge sharpness: tweak print margins and transfer temps. – Color consistency: adjust color management and printer profiles as needed. – Manage expectations: use iterative testing and validated gang sheet templates. |

| Section 4: Practical Tips and Best Practices (DTF gang sheet design tips, DTF sheet layout) | – Use a consistent grid size to build speed and reduce errors. – Maintain a printer/consumables maintenance log. – Document ideal transfer settings (temp, pressure, time) for fabrics. – Plan for scalability across garment sizes and placements. – Create a dedicated, organized workspace with good lighting to spot misalignment. |

| Section 5: Real-World Scenarios and Case Studies | – Small-batch fashion line uses gang sheet workflow to minimize waste and lead times. – Custom apparel shop combines multiple client designs on a single sheet for efficiency. – Event merch production uses gang sheets for large volumes with consistent color and crisp edges. |

| Section 6: Tools, Resources, and When to Invest | – Software/plugins for gang sheet design improve placement and export; a dedicated GangSheet Builder reduces errors. – Clear SOPs help training and consistency. – Reliable suppliers for film, inks, and transfer paper keep the process predictable. |

| Conclusion (Base Content) | The journey from concept to cut with a DTF GangSheet Builder is a practical, repeatable path that blends creativity with production discipline. By focusing on intelligent layout, color management, and robust printing and cutting workflows, you can achieve high-quality transfers at scale. Remember the core ideas: solid DTF sheet layout, careful design alignment, a reliable DTF printing workflow, and precision during cutting. With these practices—and the right toolkit—you’ll be well-equipped to deliver compelling designs that transfer cleanly and consistently across garments, while maintaining efficiency and profitability. |

Summary

HTML table with key points about the DTF GangSheet Builder base content.