DTF gangsheet builder: From concept to print in minutes

DTF gangsheet builder is a game-changing platform that streamlines concept-to-print workflows, letting teams move from idea to production with precision, while providing clear visual guidance, template support, and scalable export options. As a gangsheet design tool, it centralizes layout decisions, ensuring consistent margins, scalable templates, and fast rearrangements across multiple designs, which accelerates review cycles and improves stakeholder confidence, so teams can iterate with stakeholders in real time and maintain a single source of truth across campaigns. The integrated DTF layout software blends asset import, color management, halftone handling, and export options so what you see on screen closely mirrors what prints on fabric, reducing guesswork. Incorporating direct-to-film printing prep elements, the tool optimizes sheet density, reduces waste, aligns color separations with your DTF printing workflow, and supports automated checks to catch misalignment before production begins. By enabling collaboration and cloud-based libraries, it helps design teams deliver production-ready gang sheets to clients faster without sacrificing quality, while maintaining audit trails and scalable security for shared projects, which also simplifies version control, licensing checks, and reviewer sign-offs as teams scale or work with external partners.

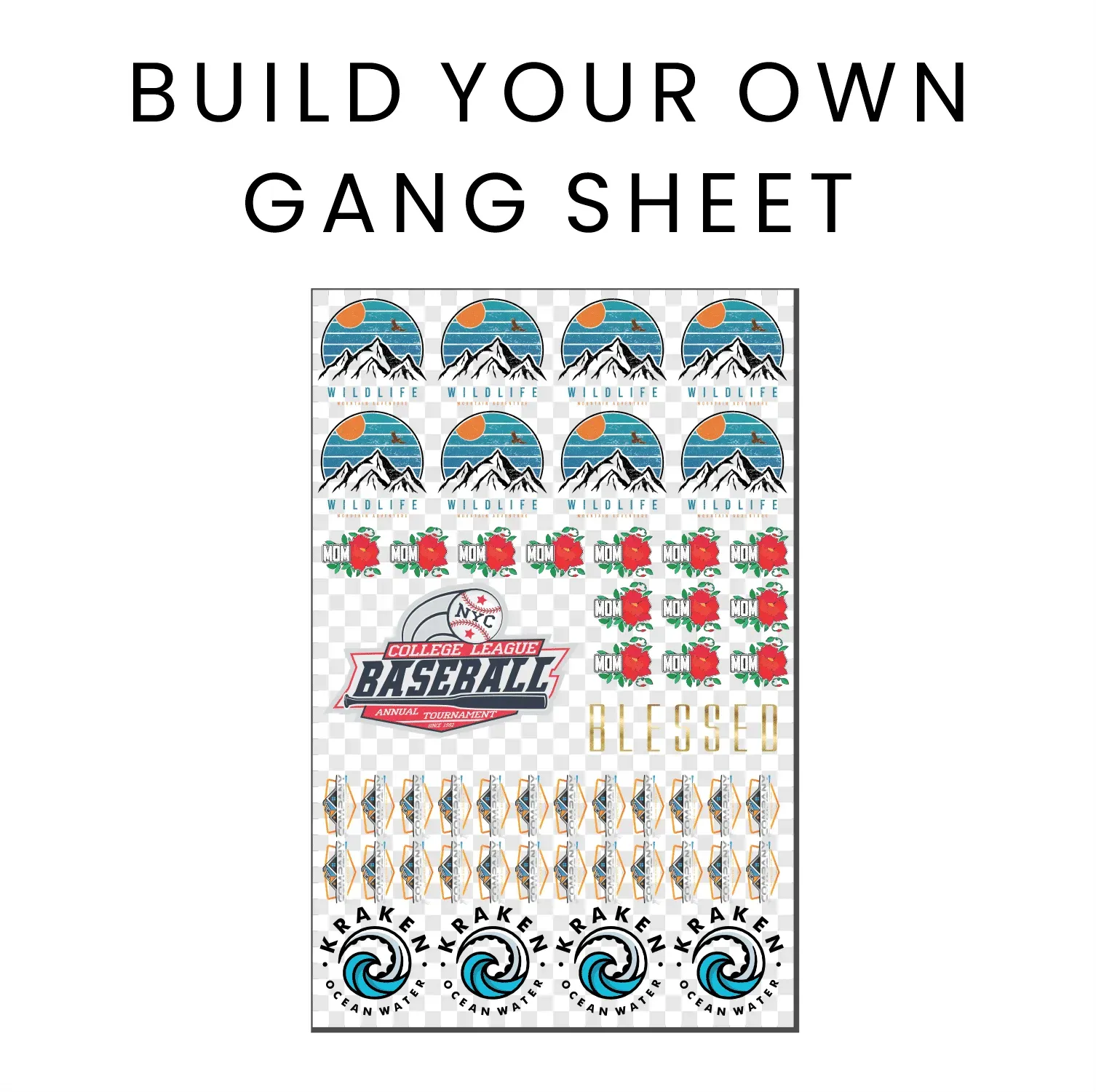

From a broader perspective, this tool acts as a transfer-sheet planner, combining multiple graphics on a single canvas to maximize fabric usage and ensure consistent color across batches. Rather than focusing on a single brand label, the approach resembles a robust layout engine that supports grid-based placement, reusable templates, automatic alignment checks, and on-screen previews for quick refinements. In industry terms, you’ll encounter concepts like garment transfer planning, DTF sheet designer, and print-ready bundle generation, names that describe the same workflow in language that resonates with studios and clients.

DTF gangsheet builder: Accelerating concept-to-print in the direct-to-film workflow

The DTF gangsheet builder transforms an idea into a production-ready gangsheet in minutes, not hours. By combining smart layout intelligence with scalable templates, it streamlines the entire process from concept to print within the DTF printing workflow. Designers can place multiple designs onto a single sheet, optimize fabric utilization, and reduce the risk of misalignment on the print bed. A dedicated gangsheet tool handles margins, bleeds, and safe areas automatically, so what you see on screen is a faithful preview of the transfer onto fabric. In practice, this means faster iteration, better consistency across runs, and a smoother handoff to prepress and production using standard export formats.

Beyond speed, the builder supports robust color management and print-ready export options. It coordinates with DTF layout software and gangsheet design tool features such as drag-and-drop grids, asset import, and batch processing to maintain color accuracy across all designs and colorways. By preserving ICC profiles and enabling direct-to-film printing prep, the tool helps producers generate reliable print files (PDF, TIFF, PNG) with separations ready for the printer driver. Cloud templates and team libraries foster collaboration, so designers, prepress, and production share a single, standardized workflow.

Optimizing layout and color fidelity with DTF layout software and gangsheet design tool

To get the most from DTF layout software and the gangsheet design tool, adopt a grid-first approach and build a library of templates for common runs. This standardization reduces guesswork, accelerates setup, and improves repeatability across batches. When paired with a rigorous DTF printing workflow, consistent margins, bleeds, and safe areas help prevent edge clipping and color drift, even as you scale from single designs to multi-design gang sheets. The result is a predictable, low-waste process that aligns with production targets and client expectations.

Implementation tips include centralized asset management, version control for artwork, and automated checks during proofing. Use the software’s color management integration to lock ICC profiles and set up color separations early, then run quick soft proofs before sending to RIP software or the printer driver. With automation options and possible AI-assisted placement, you can further optimize sheet density while maintaining print integrity, ensuring that direct-to-film printing prep stays smooth from design handoff to production.

Frequently Asked Questions

What is a DTF gangsheet builder and how does it fit into the DTF printing workflow?

A DTF gangsheet builder is a dedicated DTF layout software (also called a gangsheet design tool) that lets you assemble multiple designs onto a single sheet for direct-to-film transfers. It optimizes sheet space, manages color separations, margins, and bleeds, and exports print-ready files compatible with your DTF printer. By integrating with color management workflows, it makes screen previews align with final prints, speeding up the entire DTF printing workflow from concept to production.

How does a gangsheet design tool improve consistency and reduce waste in direct-to-film printing prep?

It provides a grid-based drag-and-drop layout, reusable templates, and scalable assets to enforce margins, safe areas, and color management across batches. Smart density optimization and batch/multi-file support reduce misprints and material waste, while export-ready formats and cloud libraries streamline direct-to-film printing prep and collaboration.

| Aspect | Key Point / Summary | Notes / Examples |

|---|---|---|

| What is a DTF gangsheet builder? | Software to assemble multiple designs on a single sheet for direct-to-film transfers; aims to optimize sheet space, manage color separations, and generate print-ready files. | Integrates with color management workflows and supports scalable artwork to keep screen visuals aligned with prints. |

| Why designers love it | Speed, Consistency, Waste reduction, File integrity, Collaboration | Fast placements, repeatable margins/bleeds, preserved asset quality, and shared templates for team alignment. |

| Core features to look for | Drag-and-drop grid; Variable sizing; Color management integration; Bleed/margins/safe area controls; Template library/presets; Asset import/export flexibility; Multi-file/batch support; Preview/proofing; Automation options | Choose tools with clear grid snapping, color profile support, flexible exports (PDF/TIFF/PNG), and scalable templates that fit your typical runs. |

| A practical workflow: concept to print | Gather assets and constraints; Create grid/templates; Import/arrange; Color management; Validate/proof; Export; Print/verify | Establish a repeatable sequence to minimize errors and speed up handoffs between design, prepress, and production. |

| Best practices | Standardize templates; Color consistency; Clear naming conventions; Proofing as a habit; Documentation | Build a centralized library of vetted templates and asset versions to streamline training and audits. |

| Common pitfalls | Overcrowding; Ignoring color workflow; Inconsistent asset versions; Inadequate proofing | Maintain margins and safe areas; always sync color profiles and run quick proofs before production. |

| The future of DTF gangsheet builders | Cloud collaboration, automation, AI-assisted layout, tighter integration with asset management and color workflows | Expect smarter placement suggestions, faster resizing, and more accurate previews to further shorten the concept-to-print cycle. |

| Real-world use cases | Small-batch fashion, Freelance designers, Print shops, Prototyping and testing | Shows where gangsheet builders deliver efficiency and consistency across varied production contexts. |

Summary

DTF gangsheet builder is a transformative tool for design teams seeking faster turnarounds and consistent prints. By consolidating layout, color management, and export into a single cohesive workflow, it enables concept-to-print in minutes rather than hours. This approach helps you maximize transfer sheet utilization, reduce waste, and maintain color accuracy across different garments, making it easier to scale creative output while preserving quality controls throughout the production process.