DTF Gangsheet Builder: Guide to Multi-Design Transfers

DTF gangsheet builder has transformed how small businesses, screen printers, and hobbyists approach garment customization. By coordinating multiple designs on a single print sheet, you can maximize productivity and reduce setup time. This aligns with DTF transfers and gang sheet printing workflows, offering a path to multi-design transfers across tees, hoodies, and more. A reliable DTF printer setup and effective heat press techniques help ensure consistent color and clean edges across every sheet. Whether you’re just starting or scaling a boutique, the gangsheet concept opens new possibilities for faster production and lower per-design costs.

Viewed through an alternative lens, the idea becomes a collective layout strategy for direct-to-film production, bundling several designs into one print run. In practice, this means using a shared grid, standardized margins, and color management to deliver reliable results across multiple items. This LSI-friendly framing emphasizes batch printing, template-driven layouts, and scalable workflows that maintain quality as orders grow. By focusing on prepress planning, palette consistency, and streamlined transfer steps, shops can boost throughput without sacrificing design integrity.

1) What is the DTF Gangsheet Builder and Why It Accelerates Multi-Design Transfers

The DTF gangsheet builder is a layout-driven approach that arranges multiple designs on a single print sheet to streamline Direct-to-Film transfers. By combining several designs into one gang sheet, you can print everything at once and then press each design onto different garments. This concept minimizes setup time, reduces film waste, and enables batch production without swapping films or screens for every print.

For small businesses, screen printers, and hobbyists, the gangsheet mindset translates into higher throughput and lower per-design costs. It also supports cohesive campaigns or collections where color palettes are shared across designs, ensuring consistency across the entire batch of DTF transfers.

2) DTF Printer Setup Essentials for Gang Sheet Printing

A reliable DTF printer setup is the foundation of successful gang sheet printing. Ensure your printer supports CMYK inks, can reproduce rich color, and is calibrated with textile-friendly color profiles to maintain fidelity across all designs. Regular maintenance and use of genuine PET film help prevent print head clogging and color shifts that could affect multiple designs on the same sheet.

In addition to the printer, you’ll need proper software and workflow tools to manage layouts, bleeds, and margins. An accurate transfer pipeline—combining the printer, adhesive powder, and heat press techniques—keeps alignment consistent across designs and minimizes setup time between batches.

3) Design and Color Management for Consistent DTF Transfers on a Gangsheet

Color management is critical when you’re stacking multiple designs on one sheet. Use consistent color profiles (CMYK or standardized RGB profiles) and soft-proof before printing to ensure that colors stay true from screen to fabric. Flattening and exporting in color-managed formats helps preserve gradients, saturations, and fine details across all designs on the gang sheet.

Develop a repeatable testing routine with a small color test sheet to validate color reproduction before committing to a full gang sheet. This practice, paired with standardized file naming and template use, reduces color drift during DTF transfers and keeps multi-design transfers aligned with the original artwork.

4) Layout Strategy: Spacing, Bleed, and Templates for Efficient Gang Sheets

The heart of successful gangsheet design is thoughtful layout planning. Create a grid that represents the print area and place each design with consistent spacing and a small bleed area to prevent edge artifacts during trimming and transfer. A well-planned layout minimizes misregistration and simplifies post-transfer alignment on garments.

Templates and standardized margins are powerful allies. Build reusable templates for common design sizes, and maintain clear reference marks for alignment during the transfer process. Organized templates accelerate production, especially when handling large batches of designs that share the same color palette.

5) Workflow Steps: From Gathered Designs to a Printed Gangsheet

Begin by gathering all designs and defining their maximum dimensions. Create a master sheet template that accommodates every artwork with the required bleeds, then arrange designs on the gang sheet within those constraints. This upfront planning reduces reworks and keeps the print head movements efficient.

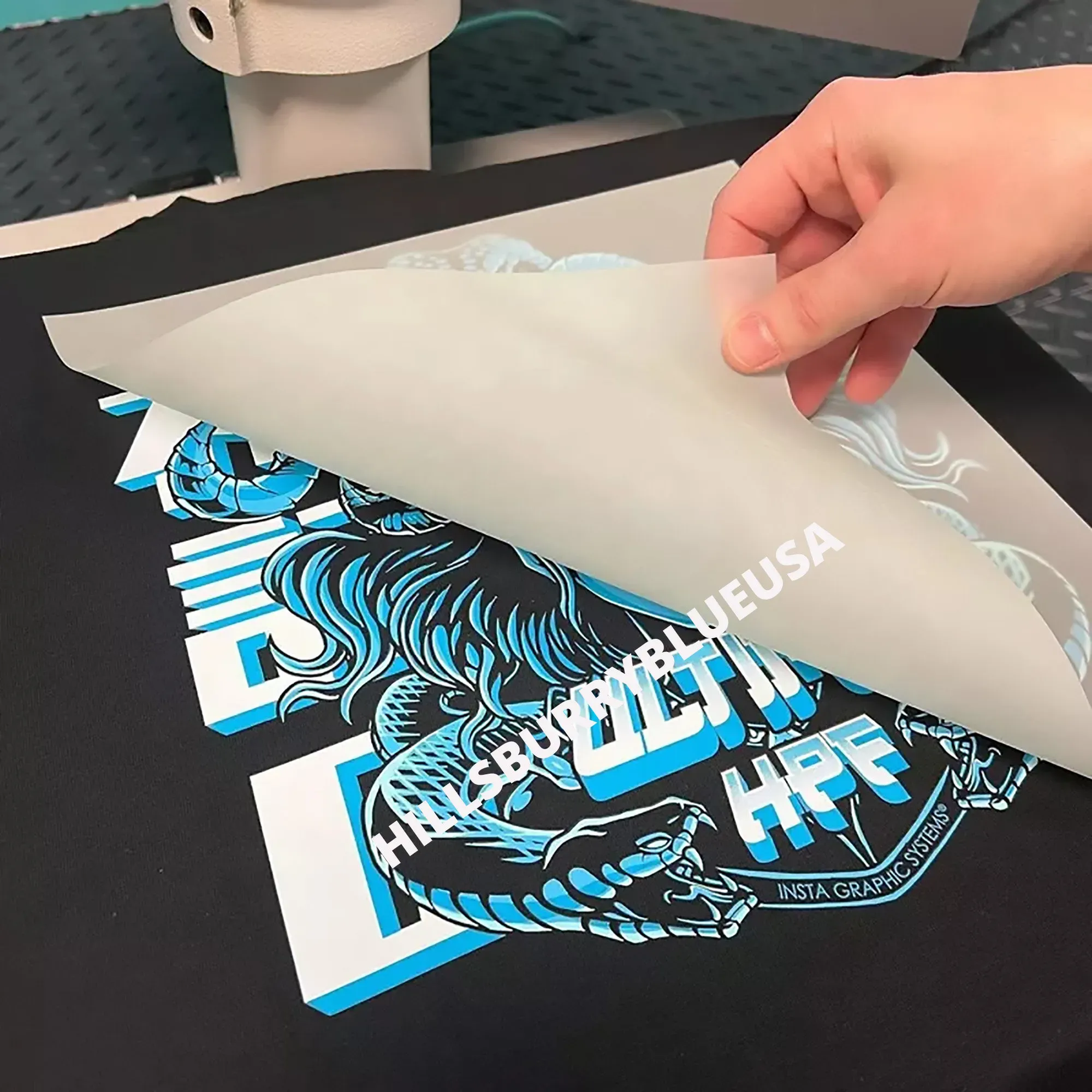

Export the print-ready gang sheet as a color-managed file, print on calibrated PET film, apply adhesive powder, and cure as recommended. After printing and curing, cut or separate designs if needed, pre-press garments, and execute the transfer with the appropriate heat press settings to achieve reliable DTF transfers.

6) Optimization and Quality Control: Heat Press Techniques and Troubleshooting in DTF

Quality control hinges on mastering heat press techniques. Use a reliable heat press with even heat distribution, consistent time/temperature profiles, and careful platen pressure to ensure multi-design transfers adhere evenly across all designs. Proper pre-pressing of garments helps remove moisture and yields cleaner results.

Common issues—like misregistration, ghosting, color shifts, or uneven heat—are best addressed with a disciplined workflow. Verify alignment marks, recheck color profiles, and run test transfers before full production. Maintaining a library of standardized gangsheet configurations and documenting transfer parameters helps scale operations while preserving design integrity.

Frequently Asked Questions

What is a DTF gangsheet builder, and how does it enable multi-design transfers in DTF transfers?

A DTF gangsheet builder is a layout tool that arranges multiple designs on one print sheet for Direct-to-Film transfers. By consolidating designs into a single gangsheet, you print many transfers in one run, increasing throughput, reducing setup time, and lowering per-design costs in DTF transfers.

How do I configure my DTF printer setup for gang sheet printing when using a DTF gangsheet builder?

Begin with a compatible DTF printer and PET film, and verify CMYK color management. Use templates to lay out all designs on one page, calibrate color profiles for textiles, and run test prints to check alignment, bleeds, and margins before the final gang sheet printing.

What are best practices for planning and spacing designs on a DTF gangsheet builder for multi-design transfers?

Collect all designs, determine max dimensions, and create a grid that represents the sheet area. Plan consistent margins, a small bleed around each design, alignment marks, and design orientation to simplify trimming and press alignment.

How can I ensure color accuracy across all designs when using a DTF gangsheet builder for DTF transfers?

Use a single color workflow: standardize color profiles across all designs, soft-proof on screen, and print a test gangsheet or color strip on the same fabric. Maintain 300–360 DPI for sharp details and stay mindful of fabric base color affecting perception.

Which heat press techniques work best for transferring designs printed on a DTF gangsheet builder?

Pre-press garments to remove moisture, use even heat distribution, and apply the recommended temperature, time, and pressure for all designs on the gangsheet. If handling multiple designs in one pass, ensure consistent press length and avoid shifting the sheet to prevent misalignment.

What common pitfalls should I watch for with a DTF gangsheet builder and how can I troubleshoot during gang sheet printing?

Watch for misregistration, color shifts, ghosting, and uneven heat. Troubleshoot by ensuring garment placement is repeatable with reference marks, double-check color profiles and printer calibration, and run small test gang sheets before full production to verify adhesion and color fidelity.

| Key Point | Description |

|---|---|

| DTF technology and purpose | DTF (Direct-to-Film) printing enables full-color designs on a flexible PET film that can be transferred to textiles, expanding options for garment customization. |

| Gangsheet concept | A gangsheet bundles multiple designs on one large print sheet, allowing you to print them together and press onto multiple garments in a single run. |

| Core benefit | Increases throughput, lowers per-design cost, and streamlines the workflow by reducing setup time and print head movements. |

| Target users | Ideal for small businesses, screen printers, hobbyists, and growing brands seeking efficient multi-design transfers. |

| Key concept of the gangsheet builder | A layout planner that optimizes spacing, bleed, and alignment so every design lands in its intended position on the garment. |