DTF Gangsheet Builder: Which Saves Time in Layout?

DTF gangsheet builder has emerged as a cornerstone of efficient print-on-demand workflows, turning complex multi-design batches into manageable jobs. If you’re juggling multiple designs, colors, and shirt sizes, you’ll appreciate how this tool accelerates layout planning and drives manual layout time savings through automation. Compared with traditional methods, the DTF printing efficiency improves as layouts are optimized, color management is standardized, and export formats align with your equipment. In this SEO-friendly comparison, we explore a software comparison between automated gangsheet generation and manual layout processes, highlighting where automation shines. Together, these features make the case for gangsheet automation as a scalable solution that reduces errors and speeds up prepress.

Viewed through an alternative lens, this approach can be described as gangsheet creation software that unifies many designs into a single prepress sheet. Other terms you might hear include prepress automation, batch layout optimization, and template-driven workflows, all pointing to the same goal of faster setup. This framing helps clarify how the technology reduces repetitive tasks in direct-to-film production and enhances consistency across colors and sizes. By comparing automation-enabled layouts with traditional drafting methods, you can assess potential time savings and quality improvements using a software comparison mindset. Ultimately, the same concept is about streamlining DTF project prep, increasing throughput, and delivering reliable results for print-on-demand campaigns.

Frequently Asked Questions

How does the DTF gangsheet builder improve DTF printing efficiency and automate layouts compared to manual layout?

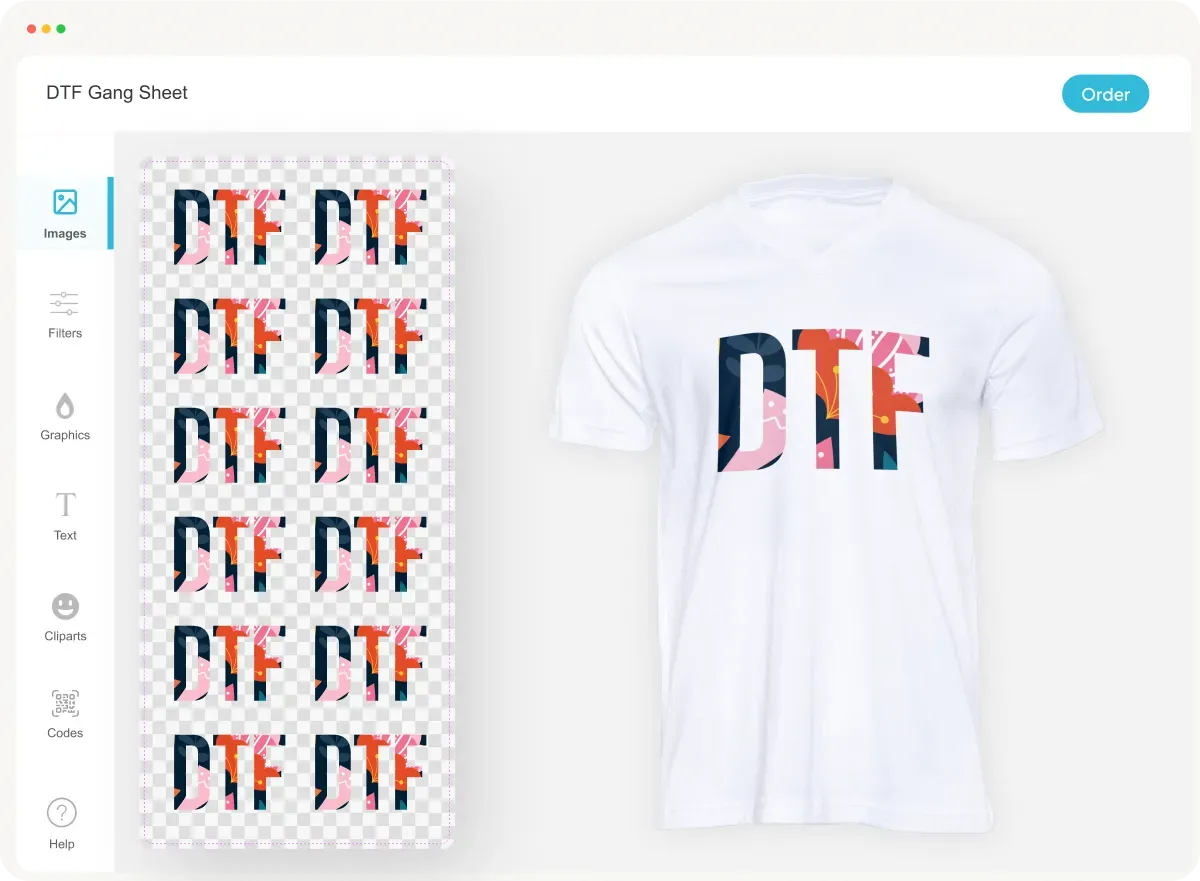

A DTF gangsheet builder groups multiple designs into a single gangsheet, automates layout calculations, color management, bleed and margin settings, and exports printer-ready files, which reduces the manual drag-and-drop work and speeds setup. In terms of DTF printing efficiency, operators often see a 30–60% reduction in prep time per job when using templates and automation, with larger catalogs delivering compounded savings across orders. It also lowers error rates through validation checks, enables batch processing, and maintains consistent color to reduce reprints. While automation is the main driver of efficiency, manual layout may still be useful for highly customized or one-off pieces, but automation is the clearer path to faster, scalable production. For many shops, this translates into measurable gains in throughput and reliability while preserving quality.

What factors should I consider in a software comparison for a DTF gangsheet builder to maximize manual layout time savings?

In a software comparison for a DTF gangsheet builder, evaluate features such as template-driven layouts, batch juggling, automatic bleed/margins, color management, and built-in validation, plus export formats and printer/RIP compatibility. Assess how well the tool supports automated gangsheet automation and asset organization, and whether training resources and onboarding are strong. To gauge real impact on manual layout time savings, run a pilot with a representative subset of products and measure prep-time before and after adoption, then factor in ROI, learning curve, and workflow integration. Also compare vendor support, update cadence, and total cost of ownership to choose a solution that fits your volume, design variability, and production pipeline.

| HTML Table: Key Points (HTML) within table content is provided below for rendering as an HTML table. | ||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

“}]}]}, |

||||||||||||||||||||||||||||||||||||||||||||

Summary

DTF gangsheet builder opens a clear path to faster production for growing print shops. This descriptive overview explains how automation standardizes layouts, reduces human error, and accelerates prepress workflows, while still acknowledging situations where manual layout remains useful. By grouping multiple designs into a single gangsheet and automating color management, bleed, and export formatting, the DTF gangsheet builder helps teams scale operations without a proportional rise in prep time. The descriptive narrative highlights time savings, improved consistency, and smoother collaboration with printers, proofing stakeholders, and production staff. It also outlines practical guidance on when to rely on templates and batch processing versus selecting a manual approach for specialized cases. Ultimately, adopting a DTF gangsheet builder can make your production line more efficient, predictable, and capable of handling growing catalogs and frequent reprints. For SEO, readers seeking insights about the DTF gangsheet builder will find clear value in understanding the balance between automation benefits and the occasional need for hands-on control, ensuring a path toward faster turnarounds, better color accuracy, and a more scalable print-on-demand workflow.