DTF Printing: The Complete Guide to Transform Apparel

DTF printing, or Direct-to-Film printing, is revolutionizing the world of apparel printing, offering a seamless way to transfer intricate designs onto fabric. This innovative printing technology simplifies the process, making it more accessible for everyone from small businesses to large clothing manufacturers. By utilizing a special film and heat transfer methods, the DTF process ensures vibrant colors and remarkable durability that stand up to everyday wear. As the fashion industry embraces advancements in printing technology, DTF printing is rapidly becoming a top choice for custom apparel creators. Join us as we explore the complete process, benefits, and recent trends that highlight why DTF printing is the future of garment decoration.

Exploring the realm of Direct-to-Film printing opens up a world of possibilities for fabric decoration. Often referred to as DTF technology, this process offers an efficient method for transferring artistic designs directly onto clothing. The modern apparel industry is experiencing a surge in demand for high-quality printing solutions, and DTF meets this need by allowing for vibrant prints on various material types. By integrating advanced techniques for film printing and adhesive application, this apparel printing method bridges the gap between creativity and practical functionality. In this article, we’ll delve into the comprehensive steps involved in DTF printing, showcasing its pivotal role in the custom apparel landscape.

Understanding the Basics of DTF Printing

At its core, Direct-to-Film (DTF) printing represents a significant leap forward in the apparel printing industry. This technology aims to streamline the process of transferring intricate designs onto fabrics, effectively merging artistic vision with cutting-edge printing technology. Unlike traditional methods such as screen printing, which require extensive resources and setup for large batches, DTF printing provides flexibility that caters specifically to both large-scale brands and small custom apparel businesses.

What makes DTF printing particularly appealing is its ability to maintain high standards of color fidelity and vibrancy. By utilizing high-quality inks, the DTF process ensures that designs come to life on a variety of materials, from cotton to polyester blends. This adaptability allows apparel printers to produce stunning results that meet modern consumer demands for uniqueness and quality in fashion.

The Step-by-Step DTF Process

The Direct-to-Film printing process encompasses several key stages, each critically important in ensuring the successful transfer of artwork onto fabric. Starting with artwork creation, designers leverage advanced graphic software to create visually appealing designs that resonate with the intended audience. This step is crucial as it lays the foundation for the subsequent phases of the DTF process.

Following the artwork creation, the film printing stage comes into play, where the design is printed onto a specialized film using a DTF printer. This technology employs a mix of color and white inks to achieve sharp and vibrant prints. The addition of a hot-melt adhesive powder post-printing enhances the bond between the ink and fabric during transfer, setting DTF apart from other methods in the realm of apparel printing.

Exploring the Advantages of DTF Printing

One of the standout benefits of DTF printing is its versatility. This method is not limited to a specific type of material, allowing it to be utilized on various fabrics such as cotton, polyester, and even blends. This adaptability opens the door for apparel manufacturers to explore designs that appeal to diverse markets without the need for multiple printing processes.

In addition to its versatility, DTF printing boasts impressive durability. The prints generated through this technique hold up exceptionally well against multiple washes, which means that customers receive apparel that not only showcases creative designs but also stands the test of time. This longevity adds significant value to products created with DTF printing, making it an economically smart choice for businesses.

Recent Innovations in DTF Technology

The realm of DTF printing is experiencing rapid advancements, particularly as technological improvements enhance production capabilities. Recent innovations include the development of eco-friendly inks that reduce harmful components, aligning the printing process with sustainable practices that contemporary consumers are increasingly seeking. This shift toward green technology not only benefits the environment but also attracts a responsible clientele.

Moreover, new DTF printers are emerging on the market that significantly increase production speeds and expand print area capabilities. These enhancements cater to the growing demand from both small custom print shops and larger apparel manufacturers. As the industry embraces innovation, DTF printing is evolving to meet changing consumer expectations while maintaining high-quality standards.

The Future of Custom Apparel with DTF Printing

As we look to the future, DTF printing is positioned to become a fundamental practice in the world of custom apparel manufacturing. Its ability to seamlessly combine artistic creativity with advanced printing technology allows designers and brands to explore new directions in fashion. This technology enables detailed prints that resonate with individual styles, making it a boon for both artists and business owners.

In addition, as fashion trends continue to evolve, the demand for high-quality, customized products will increase. DTF printing is perfectly poised to meet these expectations, offering a blend of quality, sustainability, and design freedom. The potential for DTF technology to further evolve, alongside its integration into eco-conscious practices, will undoubtedly shape the future of fashion in meaningful ways.

Why Choose DTF for Your Apparel Print Needs?

Choosing DTF printing over traditional methods might be one of the best decisions for businesses looking to expand their apparel offerings. The unique ability to produce intricate designs on various fabric types without compromising quality is a significant advantage. For small businesses, this means no need for extensive inventory of screen printing equipment and fewer upfront costs, making custom apparel more accessible for new entrepreneurs.

Additionally, DTF printing facilitates short runs at economical prices, allowing brands to cater to niche markets and unique design requests. This strategy not only enhances customer satisfaction by offering personalized products but also encourages creativity within the design process. As a versatile and cost-effective solution, DTF printing helps brands stand out in a crowded marketplace.

Frequently Asked Questions

What is the DTF printing process and how does it work?

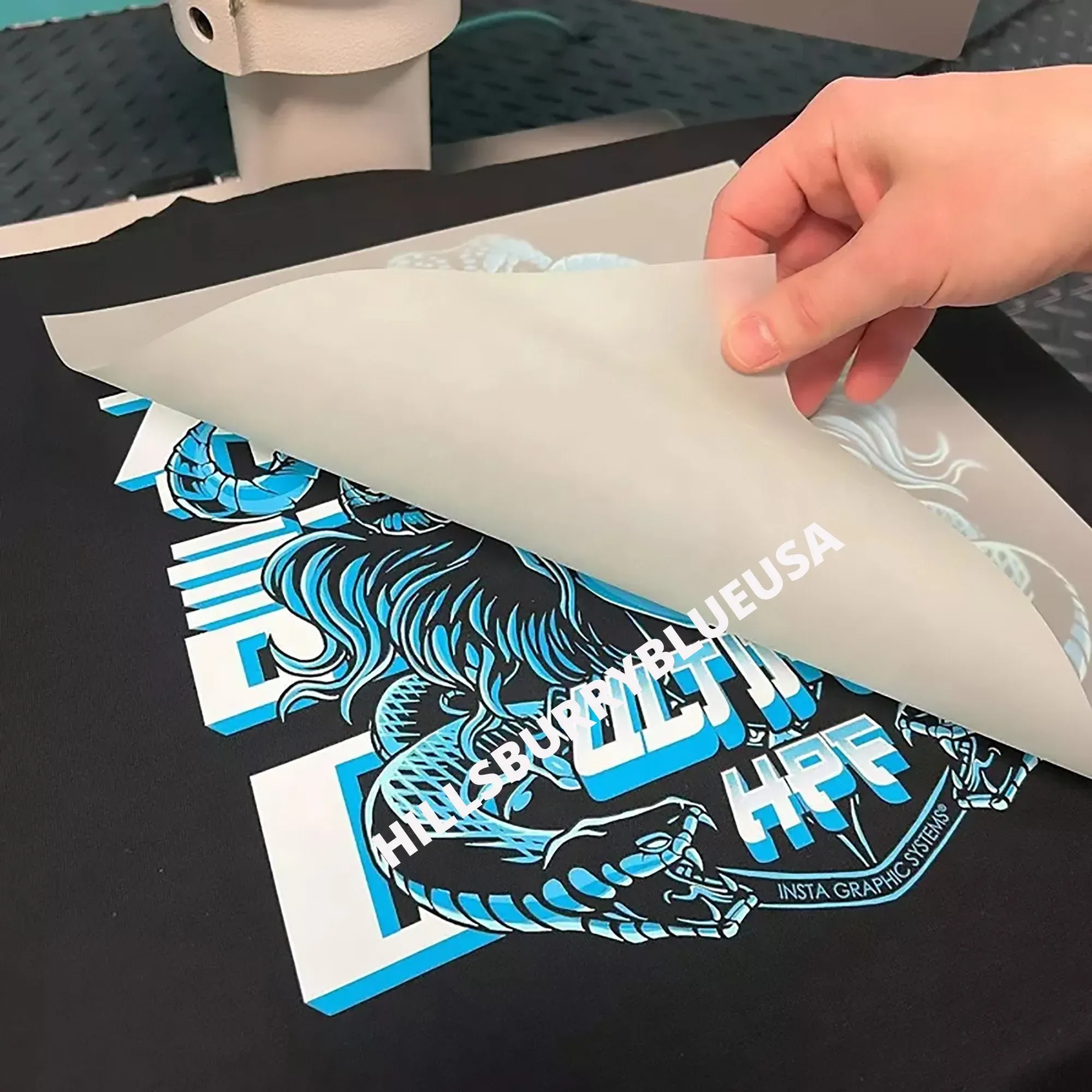

The DTF printing process, or Direct-to-Film printing, involves several steps starting from artwork creation, where designers craft images using graphic software. Next, the artwork is printed onto a specialized film using a DTF printer with vivid inks. The film is then sprinkled with a hot-melt adhesive powder, cured with heat to activate the adhesive, and finally, transferred onto the desired fabric using a heat press. This technology allows for durable and vibrant designs on various apparel materials.

What are the advantages of using DTF printing for custom apparel?

DTF printing offers numerous benefits for custom apparel, including versatility on various fabrics like cotton and polyester, excellent color fidelity for vibrant designs, and durability that withstands multiple washes. Additionally, it is cost-efficient for low to medium volume runs, significantly reducing waste compared to traditional methods like screen printing.

How does DTF printing differ from traditional screen printing?

DTF printing differs from traditional screen printing in several ways. While screen printing requires separate screens and extensive setup for each color, DTF printing uses a film to transfer full-color designs in a single process. This allows for quicker turnaround times, less setup cost, and greater adaptability, especially for complex artworks and small batch orders.

Can DTF printing be used on all types of fabrics?

Yes, DTF printing can be applied to a wide range of fabrics, including cotton, polyester, and their blends. This adaptability makes it suitable for various types of apparel, including t-shirts, hoodies, and sportswear, providing quality prints regardless of the fabric material used.

Is DTF printing environmentally friendly?

Recent developments in DTF printing technology have led to more eco-friendly practices, including the formulation of inks with reduced harmful components. As the DTF process continues to evolve, it is increasingly adopting sustainable methods, making it a greener option in the custom apparel industry.

What types of businesses benefit from DTF printing technology?

DTF printing technology benefits a variety of businesses, from small custom apparel shops to large-scale garment manufacturers. It is particularly advantageous for businesses looking to create unique designs quickly and efficiently, accommodating both low and high demand for custom apparel without the excessive waste typical of traditional printing methods.

| Step | Description |

|---|---|

| 1. Artwork Creation | Designers create detailed graphics for fabric printing using design software. |

| 2. Film Printing | Artwork is printed onto special film with vibrant inks for transfer. |

| 3. Powder Application | Hot-melt adhesive powder is applied to wet ink to ensure a strong bond. |

| 4. Curing Process | Heat is applied to activate the adhesive, bonding it to the ink. |

| 5. Transfer to Fabric | The cured film is pressed onto fabric using heat and pressure to transfer the design. |

| 6. Cooling and Peeling | The film is peeled away after cooling, leaving the design embedded in the fabric. |

Summary

DTF printing is a groundbreaking method that revolutionizes the way artistic designs are transferred onto apparel. By merging creativity with cutting-edge technology, DTF printing provides a seamless process that not only enhances the visual appeal of clothing but also ensures durability and versatility. This technique stands out in the custom apparel industry due to its efficiency, color fidelity, and cost-effectiveness, making it an ideal choice for businesses of all sizes. As advancements continue to emerge, the potential of DTF printing will expand further, solidifying its role in modern fashion and allowing designers to elevate their work while catering to consumer demand for quality and sustainability.