DTF Printing: The Magic of Transforming Designs to T-Shirts

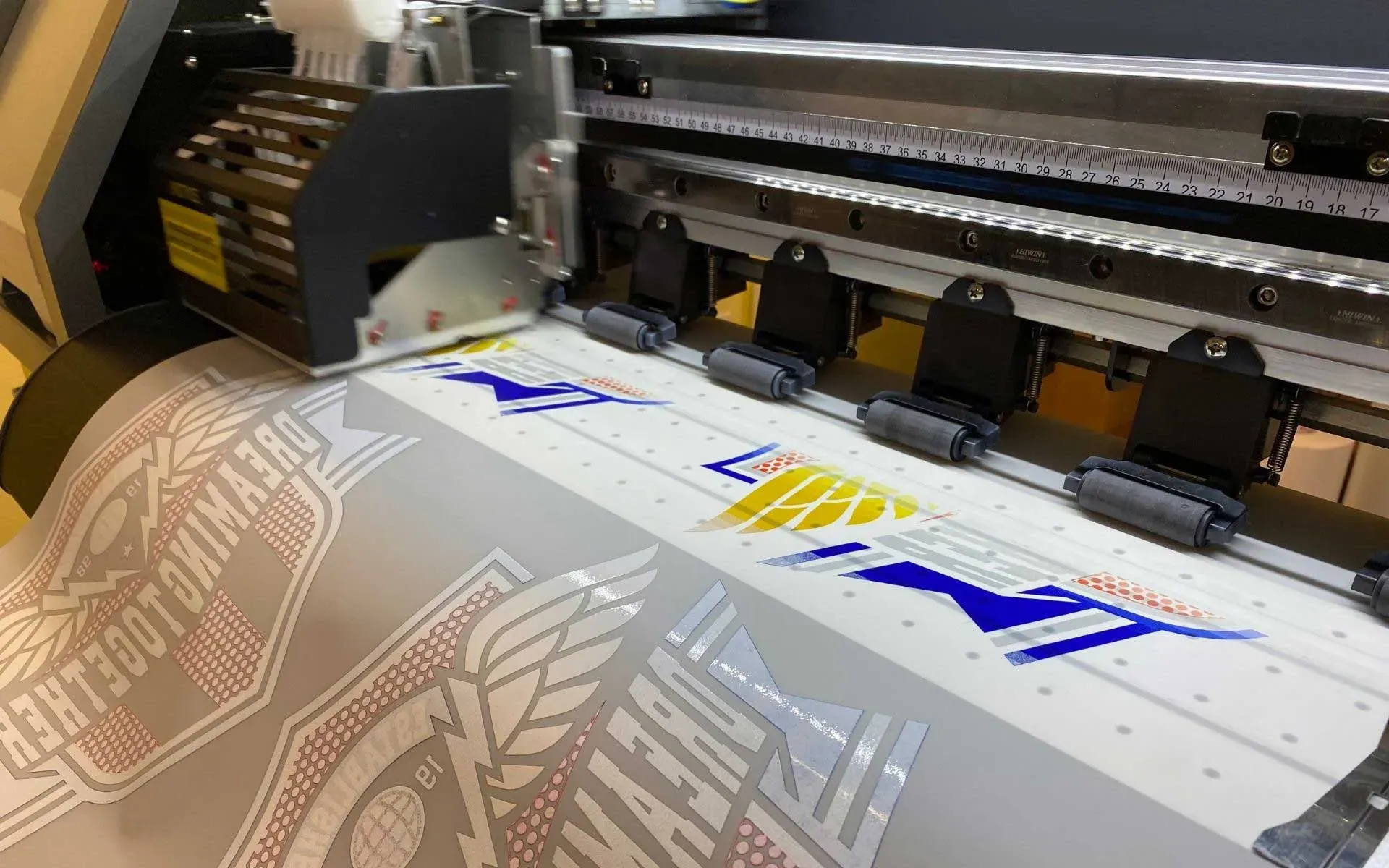

DTF printing, or Direct-to-Film printing, has swiftly emerged as a game-changer in the realm of garment decoration, allowing for the intricate transfer of designs onto t-shirts and other textiles. This innovative printing technology merges digital precision with artistic creativity, providing businesses a powerful solution to meet the rising demands for high-quality and vividly printed apparel. In recent years, the benefits of DTF printing have become increasingly evident, from its capability to produce vibrant colors on diverse fabrics to its cost-effectiveness for small production runs. With a strong emphasis on sustainable printing processes, DTF technology not only elevates design possibilities but also aligns with eco-conscious consumer values. As we explore the multifaceted applications of DTF printing, it becomes clear that this approach is revolutionizing the fashion industry and shaping the future of textile printing.

The innovative world of Direct-to-Film (DTF) printing is transforming how artists and businesses approach fabric decoration. Through this unique printing technique, intricate artwork can be effortlessly transferred onto a variety of garments, from t-shirts to activewear, echoing the demand for dynamic and personalized clothing. DTF technology leverages advanced digital processes to ensure vibrant colors and high-quality finishes that appeal to modern consumers. Furthermore, this eco-friendly method emphasizes sustainability by utilizing renewable materials in its production, thus appealing to a growing market that values environmental responsibility. As we delve deeper into the benefits and applications of DTF printing, it becomes evident why it is gaining traction within the apparel industry.

Understanding the Fundamentals of DTF Technology

Direct-to-Film (DTF) technology is an innovative approach in printing, designed to enhance the way visuals are applied to fabric. It begins with a digital design created using advanced graphic software, ensuring that the initial workflow is seamless and efficient. This digital process minimizes errors and increases the creative possibilities for designers, making it an invaluable tool in garment customization. The steps involved in DTF printing demonstrate how this technique can revolutionize the garment industry by providing high-quality prints with exceptional detail.

Once the design is finalized, the DTF printer uses a special type of ink that adheres well to the film and fabric. This aspect is crucial in elevating the quality of the final product. Traditional methods often limit the intricacy of designs due to color restrictions and process difficulty; however, DTF printing excels in these regards. Moreover, advancements in print technology continue to enhance the reliability and consistency of DTF prints, ensuring businesses can meet the ever-increasing demand for custom apparel.

The Advantages of DTF Printing Over Traditional Methods

DTF printing brings numerous advantages that make it an appealing choice over traditional screen printing methods. One of the most compelling benefits is the vibrancy of colors produced through DTF technology. The inks used in DTF printing are formulated to yield deeper, richer colors that maintain their integrity over time. This enhancement allows designers to create visually striking garments that capture consumer attention, transforming everyday apparel into wearable art.

Another notable advantage is the versatility in fabric compatibility. DTF printing can be applied to a wide range of materials beyond just cotton, including poly blends and synthetics, making it ideal for various fashion applications. This flexibility not only caters to diverse consumer preferences but also empowers businesses to explore innovative product lines without being constrained by material specifics. As a result, the many benefits of DTF printing solidify its status as a leading technique in modern garment decoration.

Latest Innovations Driving DTF Printing

Recent innovations have significantly driven the improvements in DTF printing technology, marking a new era for the industry. Advancements in ink formulations have led to more eco-friendly options that align with consumer preferences for sustainable products. These new inks not only reduce environmental impact but also enhance the print quality, ensuring that designs remain vibrant and long-lasting even after multiple washes.

Moreover, technological enhancements in film materials and adhesion processes have optimized the performance of DTF prints. The ability to create sharper details and vibrant colors has become more pronounced, elevating the standard for garment decoration. As businesses embrace these innovations, they position themselves to tap into the thriving market for customized apparel, meeting the demands of consumers eager for unique and high-quality garments.

Environmental Impact and Sustainability in DTF Printing

As environmental awareness continues to grow among consumers, the push towards sustainable printing processes such as DTF is becoming increasingly relevant. DTF printing is at the forefront of this shift, as manufacturers are exploring eco-friendly inks and recyclable substrates to minimize waste and reduce the overall carbon footprint. This sustainability aspect makes DTF not only a practical choice for businesses but also aligns with the values of environmentally-conscious consumers.

The process of DTF printing also contributes to sustainability by minimizing material waste compared to traditional methods. With the capability to manage small runs and produce customized designs without significant setup costs, DTF technology encourages brands to offer limited edition items that appeal to consumers seeking originality, fostering a more sustainable consumption model in the apparel industry.

Exploring DTF Printing Applications Beyond T-Shirts

While t-shirts remain a primary canvas for DTF printing, the applications of this technology extend far beyond traditional garments. DTF printing is making its mark in various sectors, including athletic wear, promotional merchandise, and even home textiles. This versatility allows businesses to cater to unique demands and create custom products tailored to specific audiences, broadening the market scope for DTF technologies.

Additionally, DTF printing has also found a niche in the production of intricate designs on materials such as polyester and blends, which are commonly used in sports clothing. This capability enhances the overall appeal of sportswear, attracting consumers who value both performance and style. Companies leveraging DTF printing can thus diversify their offerings and engage with a broader customer base, showcasing the adaptability and potential of this printing method.

Future Trends in DTF Printing and Market Growth

The future of DTF printing looks bright as its popularity continues to soar in the garment decoration market. Current trends suggest a sustained growth trajectory fueled by rising demand for personalized and branded apparel. As brands increasingly recognize the potential of DTF technology for producing high-quality prints efficiently, more companies are expected to incorporate this method into their production processes, shaping the future of how garments are created and sold.

Moreover, as the industry embraces technological advancements, new innovations will likely emerge to further enhance the quality and capabilities of DTF printing. This evolution will not only create more opportunities for businesses to leverage customized solutions but will also drive competition in the marketplace, leading to improved products and services for consumers. In conclusion, DTF printing stands at a crossroads of innovation and consumer demand, setting the stage for a dynamic future in the apparel industry.

Frequently Asked Questions

What is DTF printing and how does it work?

DTF printing, or Direct-to-Film printing, is a modern method for transferring designs onto fabrics. It involves printing a design onto a special film, applying adhesive powder, curing it, and then heat transferring it onto various textiles. This technology allows for vibrant colors and intricate details on t-shirts and other garments.

What are the benefits of DTF printing compared to traditional methods?

The benefits of DTF printing include vibrant colors, versatility in fabric types, and durability of prints. Unlike traditional methods like screen printing, DTF technology allows for intricate designs and a broader color range, making it ideal for small batch productions and customized orders.

In what applications can DTF printing be used?

DTF printing can be used for a variety of applications including t-shirts, sportswear, promotional items, and home textiles. Its versatility allows businesses to cater to diverse needs, from custom apparel to unique decorative pieces.

How does DTF technology align with sustainable printing processes?

DTF technology aligns with sustainable printing processes by utilizing eco-friendly inks made from renewable resources and recyclable film substrates. This focus on sustainability appeals to consumers who prioritize environmentally friendly practices in apparel production.

Can DTF printing withstand frequent washing?

Yes, DTF printing is known for its durability. The prints created using DTF technology can withstand multiple washes without fading or cracking, making them suitable for daily wear garments like t-shirts.

What advancements are being made in DTF printing technology?

Recent advancements in DTF printing technology include improved ink formulations, better film substrates, and enhanced adhesion techniques. These innovations contribute to increased color vibrancy and print clarity, ensuring high-quality outputs for various applications.

| Key Points | Details |

|---|---|

| What is DTF Printing? | A printing method that transfers designs from a film to fabrics using a heat transfer process. |

| How DTF Printing Works | Involves five steps: Design Creation, Transfer to Film, Curing, Heat Transfer, and Peeling. |

| Benefits of DTF Printing | Includes vibrant colors, versatility across fabrics, durability in washing, and cost-effectiveness for small runs. |

| Recent Developments | Increased popularity, technological advancements in print quality, emphasis on sustainability, market growth trends, and diverse applications. |

Summary

DTF printing is quickly establishing itself as a revolutionary method in the world of garment decoration. With its unique ability to produce high-quality artwork directly on various textiles, DTF printing caters to a high consumer demand for vibrant and custom designs. This innovative printing technique not only delivers on aesthetics but also offers durability and cost-effective production, especially for small batches. The ongoing advancements in technology and a growing emphasis on sustainability are further positioning DTF printing as a leading choice for businesses in the fashion and apparel sector. As consumer expectations evolve, embracing DTF printing ensures that you can provide standout products that reflect quality, creativity, and modern design trends.