DTF Supplies: The Ultimate Guide for Your Business

In the ever-evolving realm of custom apparel printing, DTF supplies stand out as essential resources for anyone looking to excel in Direct-to-Film printing. This innovative technology not only revolutionizes how designs are transferred onto fabrics, but it also opens a world of possibilities for creativity and efficiency. To navigate the bustling landscape of DTF printing materials, understanding the best DTF films, inks, and equipment is crucial for achieving high-quality results. With an array of options available, choosing the right DTF supplies can significantly enhance the final product, ensuring vibrant colors and durable prints. In this guide, we’ll delve into the vital components of DTF printing and how to maximize your business’s potential.

In the dynamic field of custom textile printing, Direct-to-Film technology represents a transformative shift towards better print quality and versatility. Various materials that support this method, including top-notch films, quality inks, and advanced printing equipment, are pivotal for achieving excellence in garment decoration. Understanding these essential elements—often referred to as DTF materials—allows businesses to remain competitive and meet customer demands. Moreover, having a grasp on adhesive powders and proper heat pressing techniques can greatly influence the longevity and clarity of printed designs. As we explore this topic further, we will uncover the critical aspects that contribute to successful DTF operations.

The Advantages of Direct-to-Film Printing in Custom Apparel

Direct-to-Film (DTF) printing represents a revolutionary approach to custom apparel, combining unmatched versatility with high-quality results. Unlike traditional screen printing, DTF printing allows designers to work with a wider range of fabrics and colors without the limitations imposed by ink types. This technique utilizes specialized DTF inks, which enhance color vibrancy and durability, ensuring that designs stand out even after multiple washes. This adaptability makes DTF an ideal choice for businesses looking to diversify their product offerings.

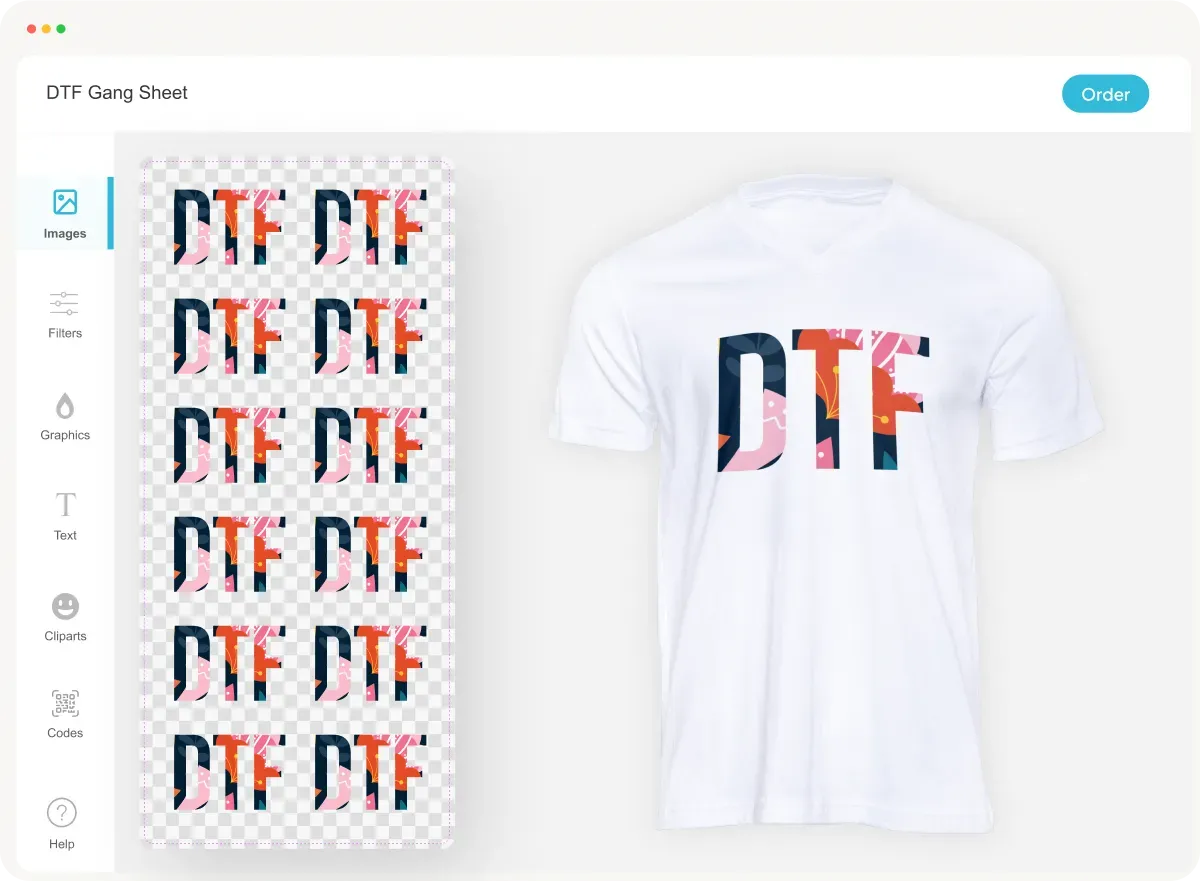

Moreover, DTF printing is particularly advantageous for low-volume jobs. Since this method does not require extensive setup like screen printing, businesses can save on both time and cost when producing smaller orders. This flexibility is essential for new businesses or those exploring niche markets. Additionally, the streamlined process makes it easier to produce intricate designs that appeal to a modern audience, ultimately allowing custom apparel companies to cater to a broad clientele.

Choosing the Best DTF Films for Quality Results

When it comes to DTF printing, not all films are created equal. The type of film you choose can make a profound difference in the quality of your prints. High-quality films are designed to provide optimal adhesion during the heat transfer process, which in turn affects the longevity and appearance of the printed design. Notable brands like Gutenberg and ProColor are widely recognized in the industry for producing films that deliver consistent results, allowing designers to achieve high-quality outputs every time.

Additionally, the characteristics of the film—such as its thickness and opacity—play crucial roles in how colors appear once printed. A better film will allow for cleaner edges and more accurate color representation. Therefore, investing in top-tier DTF films is essential. By selecting the best DTF films, sellers can ensure that every item meets the high expectations of their customers, which in turn will build trust and enhance brand loyalty.

Essential DTF Inks for Vibrant and Durable Prints

The choice of DTF inks is pivotal for anyone serious about producing high-quality apparel prints. Utilizing inks that have been specifically formulated for DTF applications can yield superior results compared to generic solutions. High-grade DTF inks, such as those provided by brands like Avery and Epson, ensure that colors not only stay vibrant but also resist fading, ensuring years of use without compromise.

When selecting DTF inks, it’s important to consider their compatibility with various fabrics as well as their covering power. A good ink offers a wide color gamut, which means it can produce bright and eye-catching designs that appeal to diverse tastes. Moreover, ensuring your inks are durable is crucial for maintaining print quality after multiple washes. Investing in the right DTF inks will ultimately define the success of your printing operations and customer satisfaction.

Critical DTF Adhesives for Successful Transfers

Adhesive powders play a significant role in the DTF printing process, and selecting the right one is key to achieving successful transfers. High-quality hot melt adhesive powders not only ensure strong adhesion but also contribute to the overall feel and appearance of your finished product. They help in binding the printed film to the fabric, maintaining both durability and vibrancy across numerous washes and wear.

When choosing adhesives, consider the specific types of fabrics you plan to work with. Various powders perform differently depending on material; therefore, testing them before large-scale production is advisable. Additionally, sourcing your adhesive from reputable suppliers can guarantee you access to high-performing products, ensuring that the prints remain intact and visually appealing over time. The right adhesive will be instrumental in optimizing the quality and longevity of every item you produce.

Investing in Reliable DTF Printing Equipment

To achieve the best results in DTF printing, having the right equipment is crucial. For instance, printers compatible with DTF inks such as the Epson SureColor series or modified Roland models are highly recommended due to their precision and reliability. These machines are designed to work seamlessly with specialized DTF materials, ensuring that the output matches the expectations of your creative designs.

Moreover, regular maintenance of your printing equipment is essential to maintain its peak performance. This includes routine cleaning and software updates, which can significantly reduce the risk of clogs and improve the quality of your print runs. By investing in high-quality printing equipment and ensuring its upkeep, you can enhance the efficiency of your DTF operations and ultimately offer better products to your customers.

Building Supplier Relationships for DTF Success

Establishing strong partnerships with suppliers specializing in DTF products is an essential strategy for businesses looking to streamline their operations. Reliable suppliers not only provide high-quality materials—such as DTF films and inks—but they also offer valuable expertise that can help troubleshoot potential problems during the printing process. This relationship can result in consistency in product quality, which is vital for any printing business aiming for long-term success.

Additionally, working closely with suppliers can lead to bulk purchasing options, potentially reducing costs. Suppliers can also provide insights into emerging trends within the DTF industry, allowing your business to stay ahead of the curve. By leveraging these partnerships, you can enhance your operational capabilities and ensure that you are utilizing the most effective DTF supplies available.

Frequently Asked Questions

What are the essential DTF supplies needed for Direct-to-Film printing?

To successfully engage in Direct-to-Film (DTF) printing, you will need several essential DTF supplies, including quality films, specialized DTF inks, adhesive powders, reliable printing equipment, and a consistent heat press. These components are critical for achieving vibrant and long-lasting prints.

How do I choose the best DTF films for my printing projects?

When choosing the best DTF films, look for reputable brands known for their performance, such as Gutenberg and ProColor. Quality films enhance adhesion and transfer results, ensuring your designs look great on fabric. Always check reviews and product specifications to find the most suitable option for your needs.

What types of DTF inks should I use for high-quality prints?

For high-quality prints in DTF printing, it’s essential to use specialized DTF inks that offer a broad color gamut and excellent opacity. Brands like Avery and Epson provide DTF inks formulated specifically for fabric transfers, ensuring vibrant and durable prints.

What role do adhesives play in the DTF printing process?

Adhesives in DTF printing, particularly Hot Melt Adhesive Powders, are vital for ensuring that prints properly adhere to the fabric. High-quality adhesives enhance durability, allowing the prints to withstand multiple washes without losing quality.

Which printing equipment is best suited for DTF printing?

When selecting printing equipment for DTF printing, it is important to choose printers that are compatible with DTF inks. The Epson SureColor series and some modified Roland models are widely recommended. Regular maintenance of your printer is also crucial for optimal operational performance.

What should I look for in a heat press for Direct-to-Film printing?

For effective DTF printing, a heat press that offers consistent temperature and pressure is crucial. Look for reliable brands like Geo Knight and Hix, known for their precision and durability in the DTF printing process. This consistency greatly impacts the quality of your final prints.

| Key Point | Description |

|---|---|

| Understanding DTF Technology | DTF is a modern printing technique using film to transfer designs to fabric, allowing for vibrant colors and intricate patterns. |

| Essential DTF Supplies | Quality supplies like films, inks, and adhesives ensure the durability and vibrancy of prints. |

| Types of Films | Choose high-quality films such as Gutenberg and ProColor for better adhesion and consistent results. |

| Quality Inks | Use specialized DTF inks from brands like Avery and Epson for vibrant and opaque prints. |

| Adhesive Powders | Hot Melt Adhesive Powders maintain the quality of prints after washing, ensuring long-lasting results. |

| Printing Equipment | Select printers compatible with DTF inks, such as the Epson SureColor series, to enhance print quality. |

| Heat Press Importance | Reliable heat press machines like Geo Knight and Hix provide consistent temperature and pressure for effective transfers. |

| Supplier Partnerships | Establishing partnerships with reliable suppliers ensures quality assurance and support for your DTF supplies. |

| Training Resources | Invest in learning through resources like YouTube and workshops to master DTF printing techniques. |

Summary

DTF supplies are essential for achieving high-quality results in your custom apparel printing business. Understanding and selecting the right films, inks, adhesives, and equipment are fundamental to mastering DTF technology. By investing in quality materials, establishing strong supplier relationships, and continually enhancing your knowledge through training, you significantly improve your output. This comprehensive approach not only ensures your prints meet professional standards but also supports your growth in the competitive market of garment printing. Quality is key; therefore, choose your DTF supplies wisely for the best results.