DTF Supplies: Transform Your Print Business Today!

DTF Supplies are essential components in the rapidly evolving world of Direct-to-Film printing, a cutting-edge technique that is revolutionizing how businesses approach garment and product printing. As demand for high-quality prints increases, the importance of selecting the right supplies cannot be overstated; they directly impact the vibrancy and durability of the final designs. DTF printing technology stands out for its cost-effective processes, enabling printers to deliver stunning results with minimal waste and setup time. The advancements in DTF supplies, including eco-friendly inks and specialized films, provide unparalleled versatility across various materials, catering to diverse client needs. By focusing on sourcing high-quality DTF supplies, businesses can unlock new potential, enhancing their offerings and driving customer satisfaction in this competitive market.

As we explore the landscape of Direct-to-Film printing, the relevance of top-notch materials becomes increasingly clear. Often referred to as film printing or transfer printing, this innovative method provides a flexible solution for high-quality apparel designs. The significance of using premium resources in this process cannot be ignored, as they are essential for achieving the vibrant colors and intricate details that today’s consumers demand. In addition to being budget-friendly, advancements in this technology allow for broader applications beyond apparel, including home decor and promotional items. Staying attuned to the latest developments in DTF-related supplies will ensure that your business remains competitive and capable of exceeding customer expectations.

Understanding Direct-to-Film (DTF) Printing

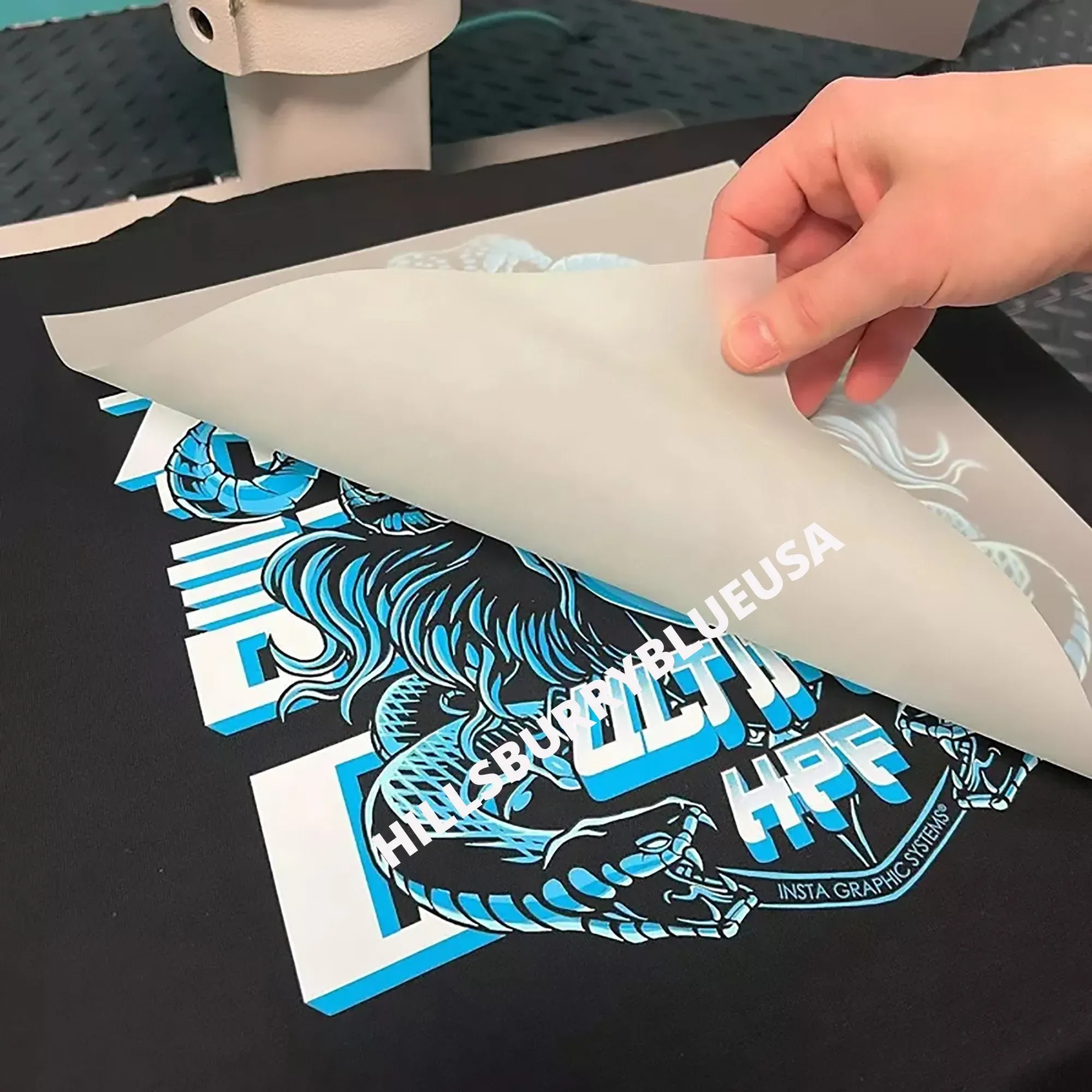

Direct-to-Film (DTF) printing represents a significant advancement in the printing industry, offering a unique blend of quality, versatility, and efficiency. Unlike traditional methods, DTF printing allows for the creation of vibrant designs on a special transfer film, which can be easily applied to various fabrics. This streamlined process not only cuts down on overall costs associated with setup and material waste but also opens doors for small to medium enterprises to enter the custom printing market. The potential applications are virtually endless, ranging from high-quality apparel designs to promotional items, making DTF a viable choice for businesses targeting multiple niches.

Moreover, the simplicity of the DTF process makes it accessible for both novice and experienced printers. By utilizing high-resolution digital artwork, printers can achieve stunning results that were once difficult to replicate with traditional methods. As the demand for personalized merchandise continues to grow, DTF printing provides companies with a competitive edge in meeting customers’ expectations for quality and quick turnaround times. Understanding these fundamentals of DTF printing is essential for any business looking to thrive in today’s printing landscape.

Advantages of DTF Supplies in Printing Technology

One of the standout advantages of utilizing high-quality DTF supplies is the substantial cost savings they provide over traditional printing techniques. With lower setup costs and reduced waste, businesses can allocate resources more efficiently, which is particularly beneficial for small operations or startups seeking to minimize expenses. DTF supplies also enable printers to produce lower quantities without compromising the quality of the final product, thus appealing to a wider customer base that may require custom or small-run orders.

Additionally, DTF supplies enhance the durability and vibrancy of prints, ensuring that the final products stand up to the rigors of everyday use. The high-quality inks and films used in DTF printing not only produce vivid colors but also ensure that designs maintain their integrity through multiple washes and wears. By focusing on sourcing the best DTF supplies, businesses can significantly boost their brand reputation and customer satisfaction, as quality is a key differentiator in the competitive printing industry.

Emerging Trends in DTF Printing Technology

The DTF printing landscape is evolving rapidly, with innovations that are reshaping how businesses operate within the industry. One notable trend is the introduction of eco-friendly printing supplies, which align with the increased consumer demand for sustainable practices. Manufacturers are developing inks and films that not only produce high-quality results but are also environmentally friendly. This shift toward sustainability encourages businesses to adopt DTF printing as a responsible choice while attracting eco-conscious consumers.

Moreover, advancements in DTF printing technology have led to more sophisticated machines that incorporate automation and precision control. These machines streamline the printing process, allowing businesses to produce high-quality prints more efficiently. Features like temperature and pressure adjustments are becoming standard, leading to fewer errors and enhanced product consistency. Keeping up with these trends enables businesses to remain competitive and capitalize on market growth opportunities.

Choosing the Right DTF Supplies for Optimal Results

When selecting DTF supplies, a critical factor that business owners must consider is supplier reputation. High-quality inputs such as films and inks directly influence the quality of the final product. Therefore, engaging with reliable suppliers who are known for their commitment to excellence is crucial. Reading reviews, seeking testimonials, and even requesting sample products can help businesses make informed decisions that align with their quality standards and operational needs.

In addition to supplier reputation, compatibility between chosen DTF supplies and target materials plays a significant role in achieving successful prints. Different fabrics react uniquely to inks and adhesive powders, so conducting thorough testing is vital. This approach ensures that businesses can assess performance across various projects, minimizing the likelihood of subpar results and ensuring customer satisfaction is consistently achieved.

Maximizing Profitability with DTF Printing

To maximize profitability within the DTF printing realm, businesses should not only focus on quality but also on the efficiency of their production processes. By embracing streamlined methods and high-quality supplies, companies can enhance their output without compromising on product excellence. A well-organized workflow that incorporates the latest DTF technologies can significantly reduce turnaround times, allowing for a faster response to customer demands. This agility can result in increased order volumes and, ultimately, higher revenues.

Moreover, offering customization options through DTF printing can attract a diverse range of clients, from individual consumers to larger businesses seeking promotional items. By capitalizing on current trends and market demand for personalized products, companies can create niche offerings that differentiate them from competitors, providing them with an additional revenue stream while maximizing their operational capabilities.

The Future of DTF Supplies and Printing

As the DTF printing industry continues to expand, the future of high-quality DTF supplies looks promising. The ongoing advancements in technology, including improved ink formulations and innovative transfer films, enable printers to deliver exceptional results that meet and exceed customer expectations. This evolution will not only enhance the quality of prints but also broaden the scope of materials that can be printed, paving the way for new creative applications and markets.

Furthermore, as businesses seek to embrace digital transformation, the integration of DTF printing technologies with existing systems is set to become more prevalent. Firms that adapt quickly can gain a significant competitive advantage. Staying updated with the latest trends and advancements in DTF supplies will ensure that businesses remain at the forefront of the industry, ready to harness new opportunities and navigate the changing landscape of print technology.

Frequently Asked Questions

What are high-quality DTF supplies and why are they important?

High-quality DTF supplies refer to premium inks, films, and adhesives used in Direct-to-Film printing. They are crucial because they enhance print durability, color vibrancy, and overall quality, allowing businesses to deliver exceptional products and satisfy customer demands.

How does DTF printing compare to traditional printing methods?

DTF printing offers several advantages over traditional methods, such as screen printing. It uses less setup time, incurs lower costs, and allows for printing on a variety of materials, making it a versatile and cost-effective option for businesses.

What advancements in DTF printing technology should businesses be aware of?

Recent advancements in DTF printing technology include the development of eco-friendly inks, automated machinery, and improved heat transfer processes. These innovations enable faster production times and better print quality, helping businesses stay competitive.

Can any fabric be used with DTF printing?

Yes, DTF printing is versatile and can be used on various fabrics, including cotton, polyester, and blends. However, ensuring compatibility between your DTF supplies and the target fabric is essential for achieving optimal results.

What should I consider when sourcing DTF supplies?

When sourcing DTF supplies, consider factors like supplier reputation, material compatibility with your projects, and the balance between cost and quality. Opting for reputable suppliers that offer high-quality DTF supplies will ultimately lead to better print outcomes.

Is DTF printing a cost-effective solution for small businesses?

Absolutely! DTF printing is a cost-effective solution for small businesses due to its low setup costs and ability to print smaller batches without sacrificing quality, making it an ideal choice for startups and custom printing operations.

| Key Aspect | Details |

|---|---|

| What is DTF Printing? | A modern technique that uses a special film for printing designs directly onto fabric, allowing for customization and high-quality results. |

| Benefits of DTF Printing | Cost-effective, versatile on materials, and enhances print durability with high-quality supplies. |

| Industry Trends | Innovative supplies, automation in printing technology, and significant market growth opportunities. |

| Key Considerations When Choosing DTF Supplies | Consider supplier reputation, material compatibility, and the balance of cost versus quality for best results. |

Summary

DTF Supplies are essential for businesses aiming to stay ahead in the competitive printing industry. This innovative Direct-to-Film printing method not only enhances the quality of printed designs but also offers cost-effective solutions that support a variety of materials. By sourcing high-quality DTF supplies, companies can ensure vibrant, durable prints that satisfy customer demands. As the printing landscape evolves with new technologies and trends, investing in superior DTF supplies allows businesses to capitalize on market growth and streamline their operations. Ultimately, focusing on quality and versatility in DTF supplies positions businesses to thrive and meet the changing needs of consumers.