DTF Transfers: A Complete Guide to Unique Designs

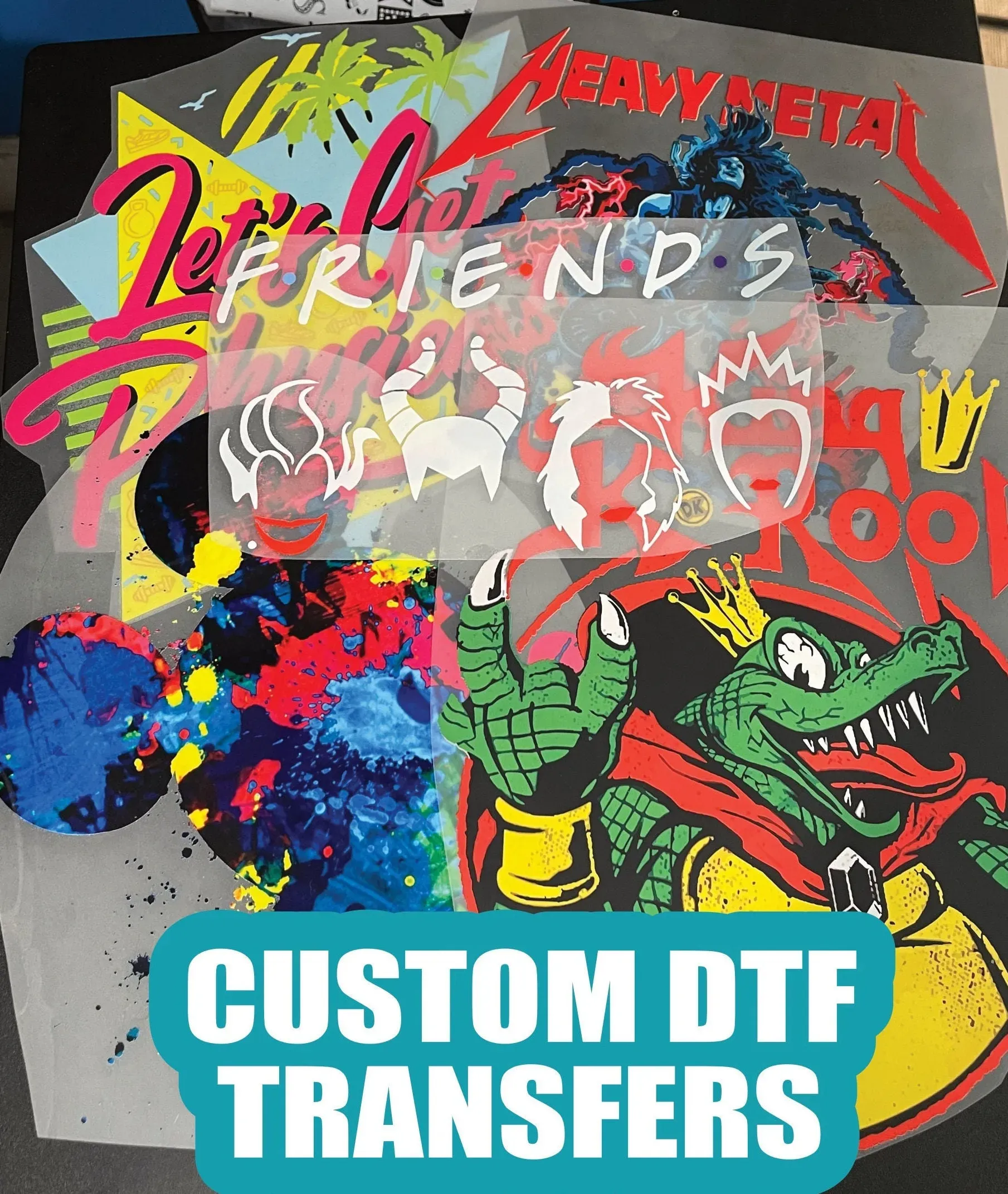

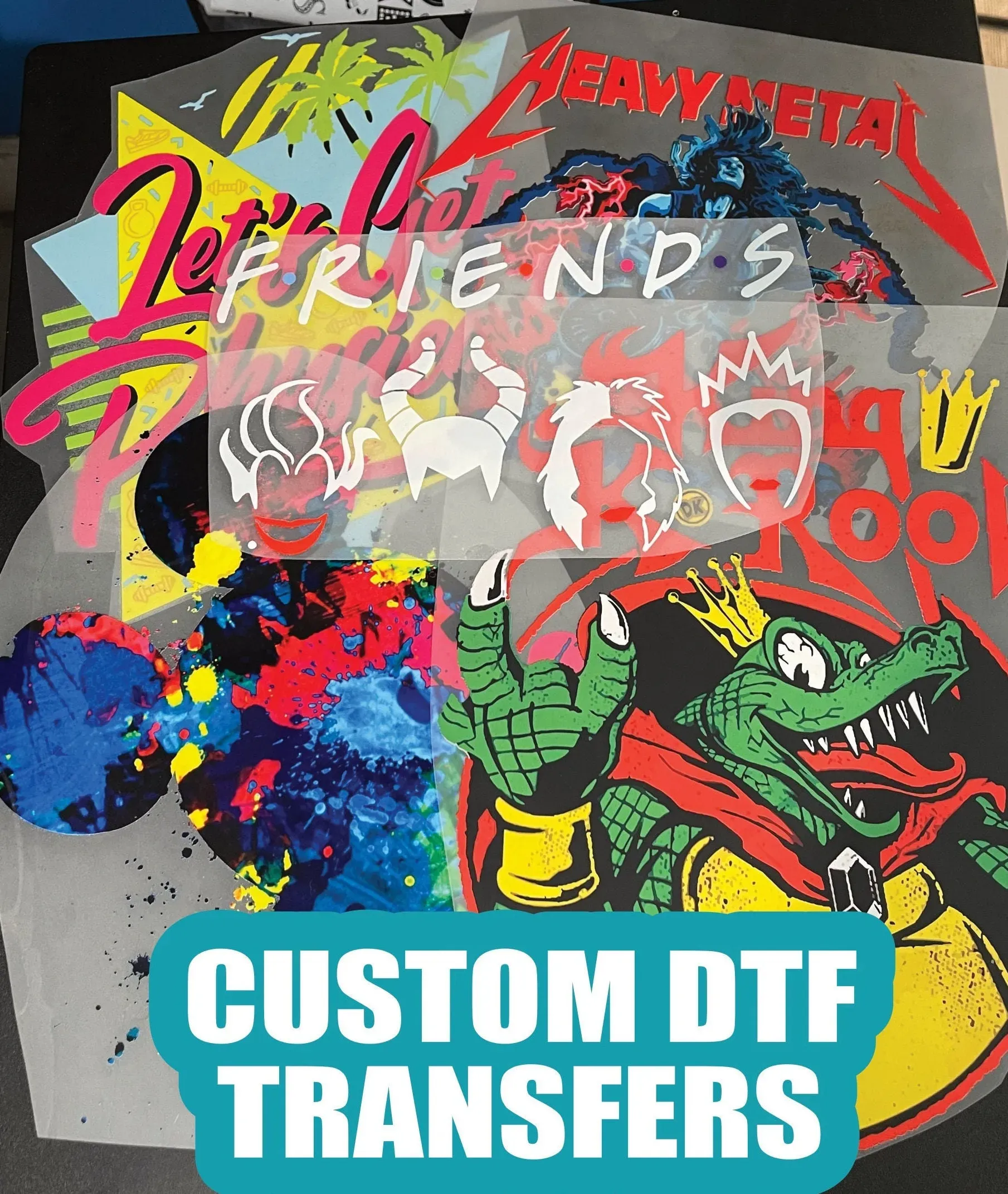

DTF transfers, or Direct-to-Film transfers, have revolutionized the custom printing landscape by allowing creators to bring vibrant, intricate designs to life on a variety of fabrics. This innovative method employs a unique DTF printing process that guarantees high-quality fabric transfers, setting it apart from traditional apparel printing techniques. With DTF, both professionals and hobbyists can easily produce stunning graphics that withstand the test of time, making it perfect for everything from apparel to home textiles. Moreover, the versatility of DTF transfers means you can unleash your creativity without limitations, whether you’re designing for promotional items or personal projects. In this guide, we will dive deep into the advantages of using DTF transfers and how you can master this cutting-edge printing technique.

The world of DTF printing, which stands for Direct-to-Film printing, offers creative individuals a unique approach to producing custom designs on fabric. This modern method of fabric decoration allows for the application of elaborate and striking graphics through a specialized transfer process. Known for its ability to deliver high-quality outputs, this printing technique provides a durable and vibrant finish that can handle the demands of everyday wear. As the printing industry evolves, techniques like this have become crucial for those looking to explore the potential of colorful and personalized apparel. Understanding the nuances of DTF transfers can significantly enhance your craft and open up opportunities for innovative design.

Understanding the DTF Printing Process

The DTF (Direct-to-Film) printing process is revolutionizing the way we create custom designs. Unlike traditional methods, DTF printing involves printing vibrant designs onto a special film that is then transferred to fabric. This technique not only produces detailed graphics but also allows for full-color applications, making it ideal for creating personalized apparel. The entire process comprises design preparation, printing onto transfer film, and the actual transfer onto the desired fabric, resulting in high-quality output that businesses and hobbyists can easily achieve.

From its inception to its current state, DTF printing has gained prominence due to its user-friendly nature. The technology is accessible to both beginners and experienced printers alike, thanks to simple steps and supportive software options. By setting up the right conditions, including humidity and temperature, users can achieve stunning results that cater to various fabric types. Understanding the fundamentals of DTF printing sets a strong foundation for leveraging this innovative technique in producing unique designs.

Benefits of High-Quality Fabric Transfers

High-quality fabric transfers, especially those created through DTF, offer numerous advantages for custom apparel businesses. One of the standout benefits is the enhanced durability these transfers present. DTF prints are designed to withstand multiple washes without fading or cracking, ensuring that the vibrant colors and intricate details remain intact over time. This durability not only enhances customer satisfaction but also positions brands as reliable providers of quality merchandise.

Additionally, the versatility of DTF transfers makes them suitable for a variety of applications. Whether designing for cotton, polyester, or blended fabrics, DTF transfers adapt well, making them an excellent choice for creating custom t-shirts, promotional items, and more. This flexibility allows businesses to tap into diverse markets and cater to specific consumer demands, ultimately streamlining their production processes and enabling them to offer unique designs.

Step-by-Step Guide to Designing Custom Graphics

Creating custom graphics for DTF transfers begins with a clear vision and effective design tools. Designers can use software like Adobe Illustrator or CorelDRAW to craft their artwork, focusing on layering techniques to enhance detail. Setting the correct document resolution, typically at 300 DPI, is crucial for achieving the high-quality output expected in DTF printing. As designers plan their artworks, considerations for color vibrancy and complexity must be front of mind, as these will significantly influence the end product.

Once the design is complete, the next phase is to prepare it for printing. This involves careful selection of a DTF printer that utilizes the right ink types to match the intended fabric. Printing the design requires precision, especially when applying adhesive to the wet ink, as this step ensures the transfer adheres well during the application process. By following a meticulous approach throughout these initial stages, designers lay the groundwork for exceptional high-quality fabric transfers.

Executing the Transfer Technique Effectively

The transfer technique in DTF printing is vital for ensuring that the design accurately adheres to the chosen fabric. Preheating the fabric eliminates excess moisture, allowing the transfer to bond effectively. After placing the transfer film on the fabric, using a heat press applies consistent pressure and temperature, which is crucial for achieving a successful transfer. Following the recommended settings for time and temperature will ensure the best possible results, maintaining the integrity of the design.

Once the printed design cools, the careful peeling of the transfer film is the final touch. This step must be approached with a gentle technique to prevent damage to the artwork. Mastering this technique not only enhances the overall appearance of the final product but also boosts the confidence of aspiring printers. Each successful transfer reinforces the effectiveness of the DTF printing process, driving creativity and innovation in custom fabric designs.

Emerging Trends in DTF Technology

As DTF printing technology evolves, several emerging trends are shaping its future. Advancements in printer technology are leading to improved color accuracy and faster processing times, promising enhanced production capabilities. Additionally, innovative adhesives are continuously being developed, improving the adhesive properties for a wider range of fabrics. These innovations streamline the workflow for users and contribute to the overall growth of the DTF market.

Refinements in transfer films are another trend to watch. New generations of films feature enhanced release properties which simplify the peeling process and guarantee high-quality outcomes. Users are now able to experiment with various fabrics and designs, pushing the boundaries of creativity. Staying informed on these trends not only empowers businesses to adapt and innovate but also allows them to maintain a competitive edge in the dynamic custom apparel landscape.

Exploring Resources for Mastering DTF Transfers

For those eager to enhance their DTF printing skills, there are an abundance of resources available. Platforms like T-Shirt Magazine and Pro World Blog provide comprehensive articles and guides that delve into the intricacies of DTF technology. These resources cover everything from troubleshooting common issues to exploring advanced techniques that can elevate one’s printing game. Engaging with these materials builds a solid foundation of knowledge crucial for successful application of DTF printing.

Additionally, tutorial videos on platforms like YouTube serve as excellent visual aids for learning the DTF process. Professional printers often share their experiences and tips, offering viewers step-by-step demonstrations that can demystify complex aspects of the technique. Combining theoretical knowledge with practical insights from experienced practitioners prepares aspiring DTF artists to navigate the challenges of custom printing, leading to impressive outcomes in their projects.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct-to-Film transfers, are a modern printing technique that allows for vibrant, full-color designs to be created on a special transfer film. This film is then applied to various fabrics like cotton and polyester through a heat press, resulting in high-quality fabric transfers that are durable and visually striking.

What makes the DTF printing process different from other apparel printing techniques?

The DTF printing process stands out from other apparel printing techniques due to its ease of use, exceptional color application, and durability. Unlike traditional methods, DTF allows for intricate designs to be printed with vibrant colors that remain intact after multiple washes, making it a preferred choice for custom designs.

Can I create custom designs using DTF Transfers?

Yes, DTF Transfers are perfect for creating custom designs. By utilizing graphic design software, you can craft intricate artwork that will be printed onto transfer film. This versatility makes DTF an excellent choice for personalized apparel and unique fabric designs.

What types of fabrics are compatible with DTF printing?

DTF printing is compatible with a wide variety of fabrics, including cotton, polyester, and fabric blends. This versatility makes DTF Transfers suitable for different applications, from apparel to home textiles, providing options for both personal and promotional items.

How durable are prints created with DTF Transfers?

Prints created with DTF Transfers are highly durable and resistant to fading, even after repeated washes. The quality of the adhesive and the printing process ensures that the designs maintain their vibrancy and detail over time, making them ideal for clothing that will see regular use.

What are the benefits of using DTF Transfers for small businesses?

For small businesses, DTF Transfers offer several benefits, including a cost-effective method for producing high-quality custom designs with minimal setup time. The user-friendly DTF printing process allows for fast production runs, catering to the demand for personalized apparel while maintaining exceptional quality.

| Key Point | Details |

|---|---|

| What are DTF Transfers? | Direct-to-Film (DTF) transfers utilize a special film to print vibrant, full-color designs onto a variety of fabrics, providing ease of use and durability. |

| Advantages of DTF Transfers | 1. High-quality output with vivid colors. 2. Versatile for various fabric types. 3. User-friendly process accessible to all levels. 4. Durable prints resistant to fading. |

| Step 1: Design Creation | Use graphic design software to create your artwork at 300 DPI, working with layers for better clarity. |

| Step 2: Printing | Select a DTF printer, apply adhesive after printing, and cure using a heat press. |

| Step 3: The Transfer Process | Preheat the fabric, apply the transfer film, and use a heat press for adherence. |

| Step 4: Finishing Touches | Consider a second heat press to enhance durability. |

| Latest Trends | 1. Improved printers with better color accuracy. 2. Innovative adhesives for better adherence. 3. Refined transfer films for easier peeling. |

| Resources | Consider T-Shirt Magazine, Pro World Blog, and YouTube channels for further learning on DTF printing. |

Summary

DTF Transfers offer an exciting opportunity for creatives in the custom printing industry to showcase vibrant and distinct designs on various fabrics. With the ease of use and versatility of this innovative printing method, anyone—from hobbyists to small businesses—can engage in the world of custom apparel design. This guide has outlined the essential steps to create your own DTF transfers, highlighting the advantages, techniques for success, and trends that can elevate your printing projects. Embracing DTF Transfers can empower you to produce high-quality, durable graphics that not only capture attention but also sustain artistic expression over time.