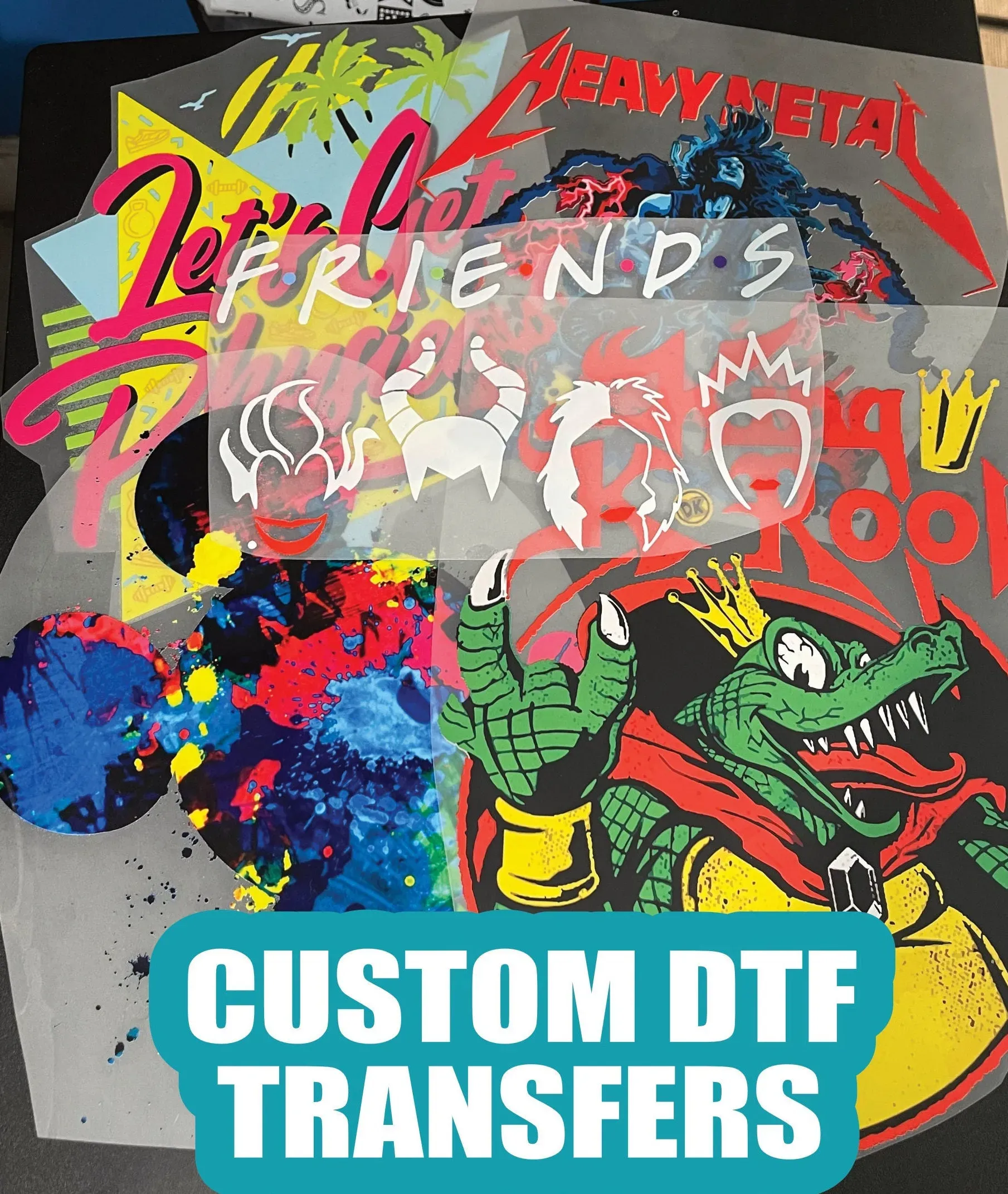

DTF Transfers: Comparing Print Methods and Their Benefits

**Direct-to-Film (DTF) transfers** are revolutionizing the textile printing landscape, offering a fresh alternative to conventional methods such as screen printing, sublimation printing, and heat transfer vinyl. Unlike traditional techniques, DTF allows for stunning, intricate designs to be transferred onto a variety of fabric types with ease. This innovative printing method is gaining momentum not only for its versatility but also for its eco-friendly printing capabilities, minimizing waste and resource consumption. As businesses and creators seek sustainable solutions, DTF stands out, enabling vibrant and durable prints without the limitations imposed by other methods. In this article, we will delve deeper into the advantages of DTF transfers and how they compare to other popular printing options.

Alternative approaches to fabric decoration, including Direct-to-Film (DTF) transfers, have begun to outpace traditional textile techniques like screen printing and sublimation. As creators and brands explore modern solutions, these innovative printing methods provide enhanced quality and flexibility compared to heat transfer vinyl and classic screen printing processes. The rise of eco-friendly practices in the industry adds a layer of appeal, as businesses strive for sustainability alongside aesthetic value. Understanding the nuances of DTF transfers can empower both hobbyists and professionals to produce exceptional results across various fabric types. Join us as we unpack the intricacies of this cutting-edge method and how it redefines the printing experience.

What Makes DTF Transfers Unique?

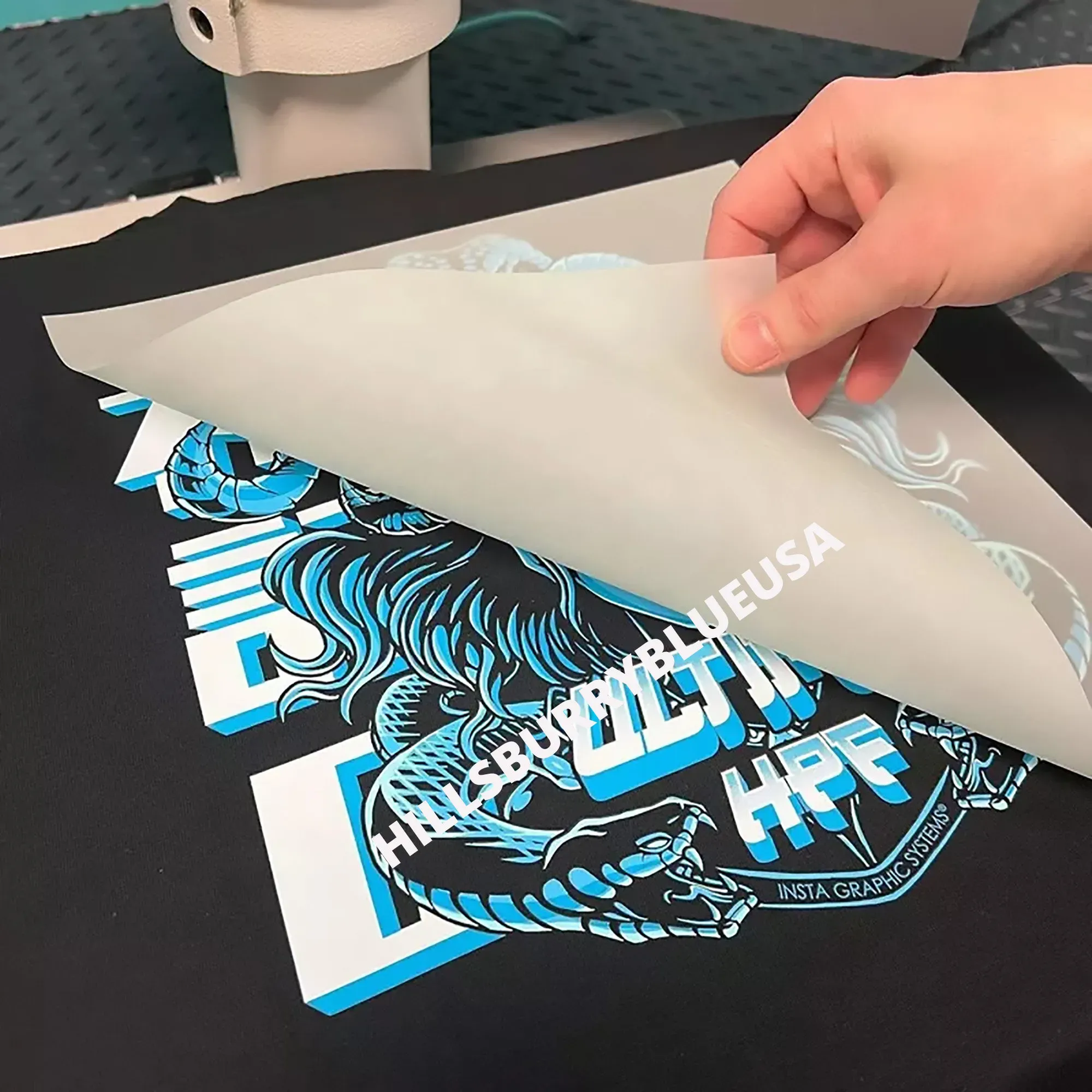

Direct-to-Film (DTF) transfers are revolutionizing the textile printing industry with their unique process and advantages. Unlike traditional methods that require complex setups and extensive preparation, DTF printing allows for seamless transfer of high-quality images onto a diverse range of fabrics. This method utilizes a specialized film that captures intricate designs with vibrant colors, enabling creators to explore their artistic boundaries without being constrained by material limitations.

The flexibility of DTF transfers stands as one of its most significant features. It can effortlessly adhere to various fabric types—including cotton, polyester, and blends—making it an ideal choice for custom apparel businesses and hobbyists alike. This versatility diverges from other methods such as sublimation, which is limited to specific materials, thus making DTF transfers a more inclusive option for a broader audience.

Comparing DTF Transfers to Sublimation Printing

While both DTF printing and sublimation serve the same purpose of transferring designs onto fabrics, their processes and results vary significantly. **Sublimation printing** involves turning dye into gas, which bonds with polyester fibers; this means it can only be used effectively on synthetic materials. In contrast, DTF transfers are applicable on a wider range, allowing for the decoration of both natural and synthetic fabrics without compromising on quality.

Additionally, DTF transfers provide a softer tactile feel compared to sublimation prints, which can occasionally exhibit a plastic-like texture due to the dyeing process. This consideration is crucial for consumers looking for comfort without sacrificing design integrity. For businesses targeting products made from varied textiles, DTF emerges as a more adaptable option, simplifying inventory management and expanding creative possibilities.

DTF Transfers versus Screen Printing

When comparing DTF transfers with screen printing, several aspects come to light. Screen printing, known for its durability and vibrant color output, often requires extensive setup involving multiple screens for different colors. This can become costly and time-consuming, making it less appealing for smaller runs and custom designs. In contrast, DTF printing allows for easy color transitions and complex designs without the need for multiple screens, thus reducing production time and cost.

Moreover, DTF printing excels in detail retention, meaning that your designs can feature fine lines and intricate patterns without losing clarity after multiple washes. This versatility resonates well with entrepreneurs who need quick, quality solutions for varied customer demands, enhancing operational efficiency while delivering an impressive final product.

Advantages of Using DTF Transfers

The benefits of DTF transfers extend beyond simple printing techniques; they encapsulate the essence of modern printing solutions. One major advantage is their remarkable durability. When applied correctly, DTF transfers resist fading and wear over time, ensuring that garments maintain their aesthetic appeal even after numerous washes. This durability is a selling point for businesses aiming to offer high-quality products that withstand the test of time.

Additionally, DTF printing promotes efficient production timelines, allowing businesses to meet quick turnaround demands. This efficiency not only satisfies customers but also optimizes operational costs, making it a preferred choice for both entrepreneurs and established companies looking to stay competitive in a fast-paced market.

Environmental Benefits of DTF Transfers

One of the standout attributes of DTF transfers is their eco-friendliness. In an age where sustainability is becoming essential, DTF technology presents a significant advantage by reducing waste in the printing process. Unlike traditional techniques that often lead to excess production and leftover materials, DTF allows for on-demand printing, aligning production closely with actual demand.

This reduction in waste not only contributes to a greener planet but also resonates with consumers increasingly concerned about purchasing practices that impact the environment. By adopting DTF transfers, businesses can promote themselves as eco-conscious leaders while attracting a customer base that values sustainability.

The Future of DTF Transfers in Textile Printing

As the textile printing industry progresses, DTF technology is poised for significant growth and innovation. With ongoing research into more eco-friendly inks and processes, we expect DTF printing to evolve further, reinforcing its position as a leading choice for fabric decoration. This evolution will likely cater to both practical efficiency and sustainability, making DTF an alluring option for businesses looking to future-proof their operations.

Moreover, the rising trend of individualization in fashion will fuel the demand for versatile printing methods like DTF. As consumers look for personalized, high-quality apparel that reflects their unique style, DTF ensures creators can keep pace with such evolving market expectations—all while keeping affordability and sustainability at the forefront.

Frequently Asked Questions

What are DTF Transfers and how do they compare to sublimation printing?

**DTF transfers** (Direct-to-Film) are a modern textile printing method where images are printed onto a special film, then transferred onto fabrics using heat and pressure. Unlike **sublimation printing**, which is limited to polyester, DTF can be applied to a variety of materials including cotton and blends. This versatility makes DTF a more practical choice for intricate designs and diverse fabric applications.

How do DTF Transfers differ from screen printing?

**DTF transfers** differ from **screen printing** by allowing for quicker production and the ability to print multiple colors without needing multiple screens. While screen printing excels in vibrant colors, it can be more costly and less efficient for small quantities. DTF offers a more economical and flexible option for custom designs, especially for smaller businesses.

Why should I choose DTF Transfers over heat transfer vinyl (HTV)?

Choosing **DTF transfers** over **heat transfer vinyl (HTV)** provides better detail and color options in a single print. While HTV typically requires layering for intricate designs, DTF allows for complex visuals without sacrificing durability or comfort, resulting in a lighter transfer that maintains fabric breathability.

Are DTF Transfers environmentally friendly compared to traditional methods?

Yes, **DTF printing** is considered more eco-friendly compared to traditional methods like **screen printing**. It minimizes waste by using less ink and supports print-on-demand production, reducing overproduction and surplus materials, which is better for the environment.

Can DTF Transfers be used on any type of fabric?

Yes, one of the standout features of **DTF transfers** is their versatility. They can be applied to a wide range of fabrics, including cotton, polyester, and blends, making them suitable for various applications compared to other methods like sublimation, which only works well on polyester.

What are the benefits of using DTF Transfers for custom projects?

The benefits of using **DTF transfers** for custom projects include their versatility on different fabric types, durability, high-quality print resolution, and efficient production processes. This makes them an excellent choice for both hobbyists and professionals seeking creative and sustainable printing solutions.

| Comparison Aspect | DTF Transfers | Sublimation | Screen Printing | Heat Transfer Vinyl (HTV) |

|---|---|---|---|---|

| Fabric Compatibility | Wide variety including cotton, polyester, and blends | Limited to polyester and treated surfaces | Best for cotton; color vibrancy can vary | Can be limiting for intricate details |

| Feel & Texture | Soft finish, less noticeable on fabric | Plastic feel on synthetic fibers | Vibrant but may feel thicker than DTF | Can feel bulky with multiple layers |

| Setup & Costs | Quick setup, economical for small runs | Long setup, costly for small quantities | Multiple screens increase costs | Requires cutting for each design |

| Detail & Color | High detail and vibrant colors | Limited by dye and fabric compatibility | Great for bold colors but not intricate designs | Intricate designs require layering |

| Environmental Impact | Minimal waste, aligns with eco trends | Potential for high waste with inks | Generates significant leftover materials | Waste from multiple vinyl pieces |

Summary

DTF transfers represent an innovative and versatile method in textile printing that stands out from traditional techniques. By leveraging high-quality printing on diverse fabrics with improved durability and reduced environmental impact, DTF transfers have become an essential choice for both amateur and professional crafters. Understanding the unique advantages of DTF transfers allows businesses to optimize their production processes and meet the growing consumer demand for sustainable and high-quality apparel.