DTF Transfers: Durable, Vibrant Prints for Apparel

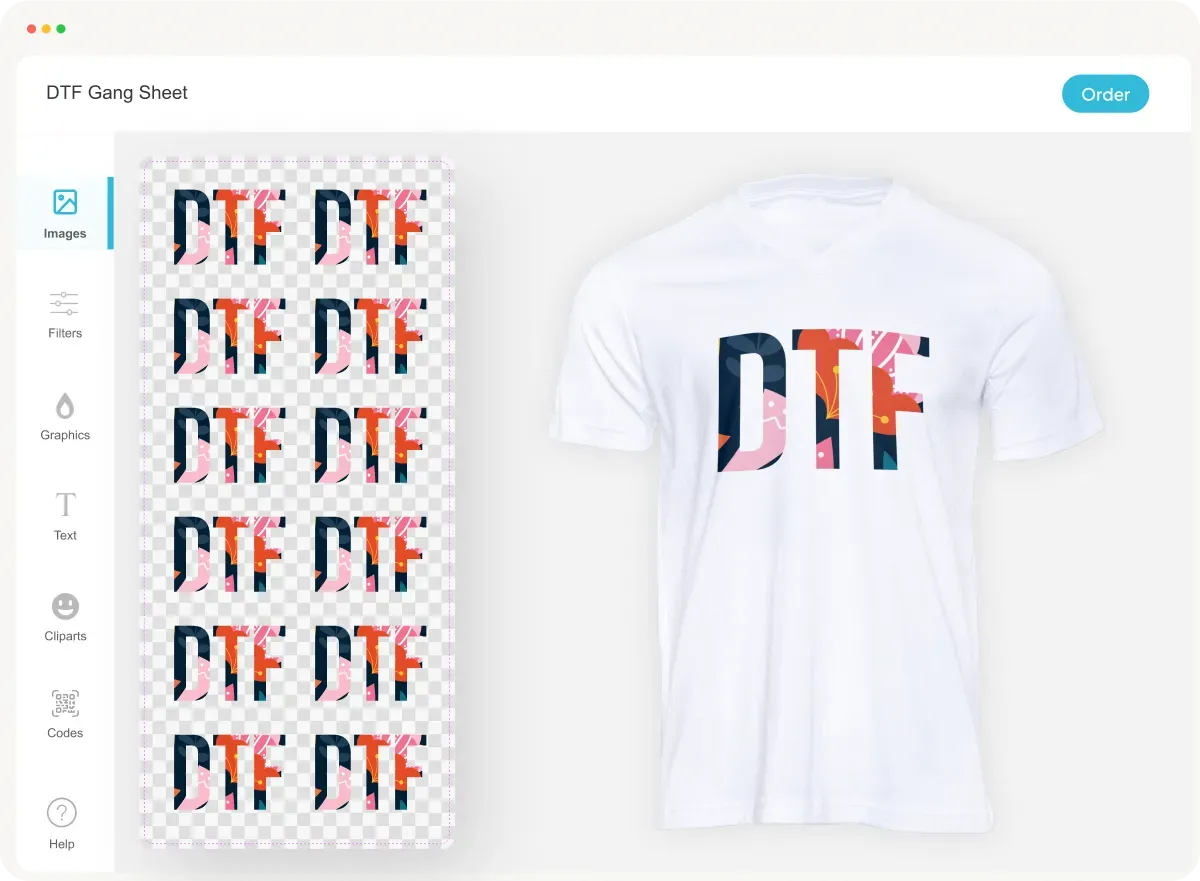

DTF Transfers have transformed how designers decorate apparel, a form of DTF printing that delivers rich color, durability, and a soft hand. This method supports vibrant prints across a broad range of fabrics, while providing durable transfers that resist wear and repeated washes. By leveraging heat transfer techniques, designers can reproduce complex artwork with precise gradients and reliable underbases. For businesses exploring garment printing with DTF, the workflow remains approachable and scalable from single-item runs to small batches. With strong color fidelity and a soft feel, DTF Transfers offer a practical path to high-quality apparel decals.

In practice, this film-based garment decoration uses a direct-to-film approach that lays down color for transfer. The direct-to-film process is widely discussed as a modern alternative to traditional screen printing, emphasizing color richness and a soft hand with the finished product. Because the method works across cotton, blends, and certain synthetics, you can achieve vibrant prints with consistent results using appropriate powders and cure settings. For newcomers, think of it as a versatile garment decoration option—an adaptable, cost-effective path within heat transfer techniques.

DTF Transfers: Durable, Vibrant Garment Printing with DTF Printing

DTF Transfers unlock durable transfers and vibrant prints by using CMYK inks plus a white underbase on a PET film. In garment printing with DTF, the design is printed onto the film, cured with an adhesive powder, and then heat-pressed onto fabric to create a soft, color-rich result.

Because the process operates on a film and powder workflow, you gain broad substrate compatibility and excellent color fidelity. With careful color management and appropriate curing, you can achieve smooth gradients, minimal halos, and long-lasting results that stand up to repeated wash cycles—hallmarks of durable transfers and vibrant prints.

Optimizing Your DTF Printing Setup: Equipment, Materials, and Heat Transfer Techniques

Setting up for DTF printing starts with choosing equipment and materials that align with your production goals, from a CMYK-plus-white printer to PET film, adhesive powder, and a reliable heat press. Understanding DTF printing workflows and the role of heat transfer techniques helps you optimize output, reduce misregistrations, and deliver consistent durable transfers.

Focus on material quality and process parameters: select films and powders designed for DTF, calibrate color management with RIP software, and establish a repeatable curing and pressing schedule. This aligns with best practices for garment printing with DTF and supports vibrant prints that endure washing and wear.

Frequently Asked Questions

How durable are DTF Transfers, and what heat transfer techniques help maximize their longevity?

DTF Transfers are designed for durability. With proper curing of the adhesive powder and precise heat press settings (typically 305–320°F / 150–160°C for 12–20 seconds with even pressure), the prints resist cracking and fading. Use high-quality PET film and adhesive powder, ensure correct fabric compatibility, and follow aftercare guidelines (wash inside-out in cold water). These practices help maintain durable transfers and vibrant results.

Which fabrics are best suited for vibrant prints with DTF Transfers in garment printing with DTF?

DTF printing works well on cotton, blends, and many synthetic fabrics when using the right adhesive powder and curing. For dark fabrics, a strong white underbase helps vibrant prints pop, while light fabrics retain brightness without extra base. Always test on a sample garment and tailor powder quality, curing, and press settings to achieve consistent, vibrant prints and durable transfers.

| Topic | Key Points |

|---|---|

| What are DTF Transfers and How They Work |

|

| Durability and Vibrancy |

|

| Process and Steps |

|

| Equipment & Materials |

|

| Materials: Choosing Right Materials |

|

| Pre-Press and File Prep |

|

| Press Settings and Techniques |

|

| Quality Control and Troubleshooting |

|

| Care and Longevity |

|

| Applications and Use Cases |

|

| FAQs |

|

Summary

DTF Transfers offer a practical path for garment decorators seeking durable, vibrant prints for a wide range of fabrics. By outlining the end-to-end workflow—from design and color management to printing, powder coating, curing, and heat pressing—this overview highlights how DTF Transfers enable high-fidelity color, durable adhesion, and a soft hand feel in everyday wear. With careful material selection, precise press settings, and ongoing quality control, DTF printing becomes a reliable method for garment decoration that delivers professional results and satisfied customers. Whether expanding an existing product line or launching a new shop, embracing DTF Transfers can boost color richness, coverage, and longevity across washes.