DTF transfers: Speed and efficiency in optimized workflows

DTF transfers have transformed textile decoration by delivering vibrant, durable designs quickly, empowering small shops and large production houses to scale with confidence. When you apply the concept of DTF transfers workflow optimization across design, prepress, printing, and finishing, you begin to see how standardized steps reduce waste and misprints while boosting output. Focusing on DTF printing efficiency means dialing in color management, film stock, and curing routines so that every job travels from concept to customer with predictable results. The method also hinges on practical DTF heat press best practices and a clear understanding of DTF transfer speed tips, since temperature, pressure, and dwell time directly influence adhesion and vibrancy across fabrics. Direct-to-film printing optimization is the umbrella that ties these elements together, guiding material selection, process integration, and quality control to deliver repeatable gains in throughput and client satisfaction.

Viewed through an LSI lens, this film-based transfer technique sits within the broader realm of garment decoration and shares common ground with heat-transfer methods. Alternative terms such as direct-to-film production, film-to-fabric printing, or transfer-on-textile workflows capture the same concept using related vocabulary, making it easier for audiences to relate regardless of their background. The emphasis remains on reliable, repeatable steps that bridge prepress, printing, powdering, and finishing to deliver consistent results. By framing the topic with these semantically related terms, readers connect the method to adjacent practices like color management, equipment calibration, curing protocols, and workflow optimization.

DTF transfers workflow optimization: Speed, Consistency, and Profit

DTF transfers workflow optimization starts with mapping the entire production path from design to finished garment. By standardizing design handoff, color management, RIP settings, powder application, and curing, shops can reduce errors and shorten cycle times. This structured approach also supports DTF printing efficiency by ensuring consistent ink laydown, color integrity, and fabric compatibility across jobs, aligning with the broader goal of Direct-to-film printing optimization.

To realize faster throughput, implement standard operating procedures, batch processing, and routine maintenance for printers and heat presses. Regular calibration, clear QA milestones, and the use of test swatches help catch issues early, minimizing reprints. This is where you can leverage DTF transfer speed tips and DTF heat press best practices to shave minutes off each transfer while preserving image quality and adhesion.

Direct-to-film printing optimization: Speed, Quality, and Heat Press Best Practices

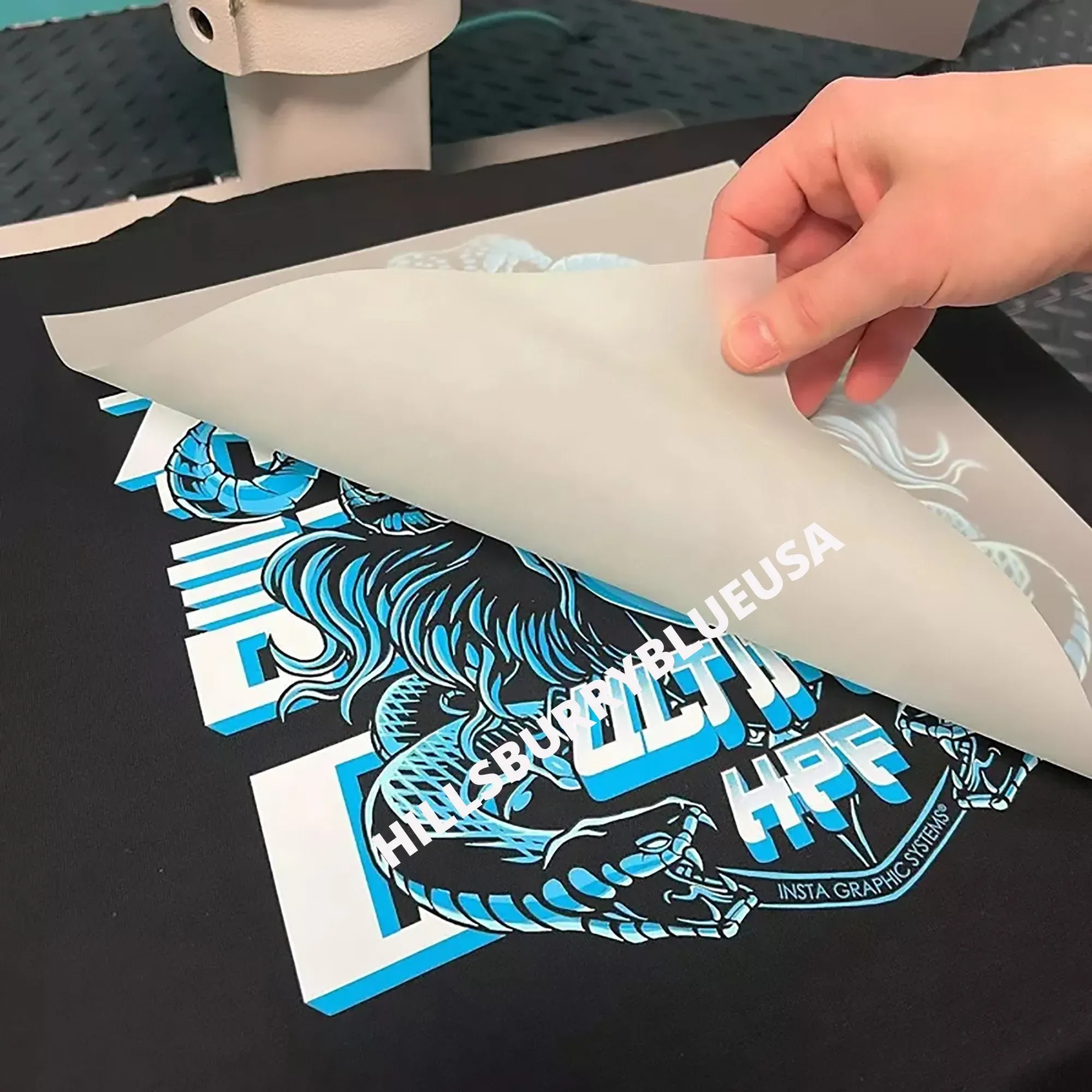

Direct-to-film printing optimization begins with choosing reliable film and ink systems, plus optimizing powder adhesion and curing parameters to achieve a strong, clean transfer. Align prepress color management with the actual garment outcome so that separations and tones translate accurately after transfer, reducing post-press adjustments and waste.

Then extend optimization into the press phase: standardize heat press procedures by fabric type, maintain stable platen temperature, and document test results to build a library of proven settings. Emphasize DTF heat press best practices and practical speed tips so operators can deliver consistent results faster without compromising durability or color vibrancy.

Frequently Asked Questions

How can I optimize the DTF transfers workflow to improve DTF printing efficiency?

This is a guide to DTF transfers workflow optimization that prioritizes speed without sacrificing quality. To boost DTF printing efficiency, standardize design and prepress with color management and a RIP, regularly calibrate the printer, select appropriate film stock and adhesive, and balance print speed with resolution. Implement consistent powdering, curing, and heat-press steps, plus finishing QC. Build clear SOPs, batch production, and ongoing training to sustain gains and reduce waste.

What DTF transfer speed tips and DTF heat press best practices should I follow for Direct-to-film printing optimization?

Follow practical DTF transfer speed tips and DTF heat press best practices to maximize throughput. Preheat the platen and ensure even heat, use fabric-appropriate dwell times and pressure, and align garments with reliable tools. Maintain protective layers to minimize cleanup, calibrate the RIP and printer for repeatable color, and implement a straightforward powder application and curing routine. This Direct-to-film printing optimization approach helps reduce downtime and improve consistency.

| Key Point | Summary |

|---|---|

| DTF transfers overview | DTF transfers are a versatile method for producing vibrant, durable designs on textiles, with speed, reduced waste, and scalability for both small businesses and large shops. |

| DTF transfers workflow | Printing designs onto a special film, applying adhesive powder, curing the powder, and transferring the design to fabric with heat and pressure; the goal is reliable, repeatable steps that minimize downtime and maximize output. |

| DTF stands out | Compared with other transfer methods, DTF transfers offer vivid color reproduction, fabric flexibility, and less material waste when well-managed, with a mindset of continuous improvement. |

| Key components: Design and prepress | Clean, color-managed design; use a RIP that matches printer capabilities; correct resolution, bleed, and margins; consistent prepress settings; clear color communication to avoid reprints. |

| Key components: Printing efficiency and consistency | Calibrate printers regularly; use appropriate film stock and adhesives; optimize speed vs. resolution; keep print path clean and nozzles well maintained to reduce waste and improve repeatability. |

| Key components: Powdering, curing, and quality control | Even powder coverage, proper shake-off and curing; consistent curing times/temperatures; quick QC on a test swatch to catch issues early. |

| Key components: Transfer and pressing | Preheat platen to around 180–190°C (356–374°F); ensure even pressure and contact; appropriate dwell time; use parchment/teflon sheets to prevent ghosting. |

| Key components: Finishing and post-processing | Allow curing, inspect for misalignment or incomplete transfer; use a finishing checklist to reduce rework and boost client satisfaction. |

| Strategies: SOPs | Document every step and train staff to follow the same sequence; regular reviews to incorporate improvements. |

| Strategies: Batch processing | Plan production in batches to maximize machine uptime; group similar designs and color profiles to minimize adjustments. |

| Strategies: Equipment maintenance | Regular maintenance of printers, heat presses, and curing equipment; keep spare parts organized; calibrate and upgrade as needed. |

| Strategies: Quality control integrated | QC checks at prepress, print, powder, and final transfer stages to detect issues early and reduce waste. |

| Strategies: Training and skill development | Ongoing operator training on DTF transfers, latest techniques, and heat press usage to troubleshoot quickly and adapt to fabrics. |

| DTF printing efficiency in practice | Focus on clean design prep, consistent film loading and powder application, test swatches for color fidelity and adhesion, and calibrate the RIP for repeatable color output. |

| DTF transfer speed tips and best practices for pressing | Preheat platen, match settings to fabric and design complexity, align garments with tools, keep protective coverings handy, and build a library of tested settings to reduce decision time. |

| DTF heat press best practices | Maintain temperature control (roughly 180–190°C), ensure even pressure, use consistent dwell times, and use protective layers to improve edge quality and handling. |

| Direct-to-film printing optimization | Select reliable films, fine-tune powder adhesion, calibrate curing, manage color profiles, and align prepress, printing, powdering, and pressing to reduce idle time. |

| Overcoming bottlenecks | Address misalignment, color variability, and powder variation with alignment checks, standardized powder methods, test runs for new fabrics, and a feedback loop to adjust SOPs. |

| Case study: ramping up production | A small shop reduced batch time by 30–40% by standardizing files, implementing SOPs, batching, upgrading to a reliable heat press, and strengthening prepress QC. |