Texas DTF for Small Businesses: Setup to Successful Prints

Texas DTF is reshaping how small brands deliver custom apparel across the Lone Star State. For entrepreneurs seeking fast, high-quality prints with lower upfront costs, DTF printing Texas offers a compelling path. A reliable workflow helps keep production lean and scalable for growing brands. This guide highlights practical steps and reputable suppliers to minimize downtime and ensure consistent finishes. By understanding the core benefits and starting steps, you can translate designs into durable, vibrant garments that resonate with local audiences.

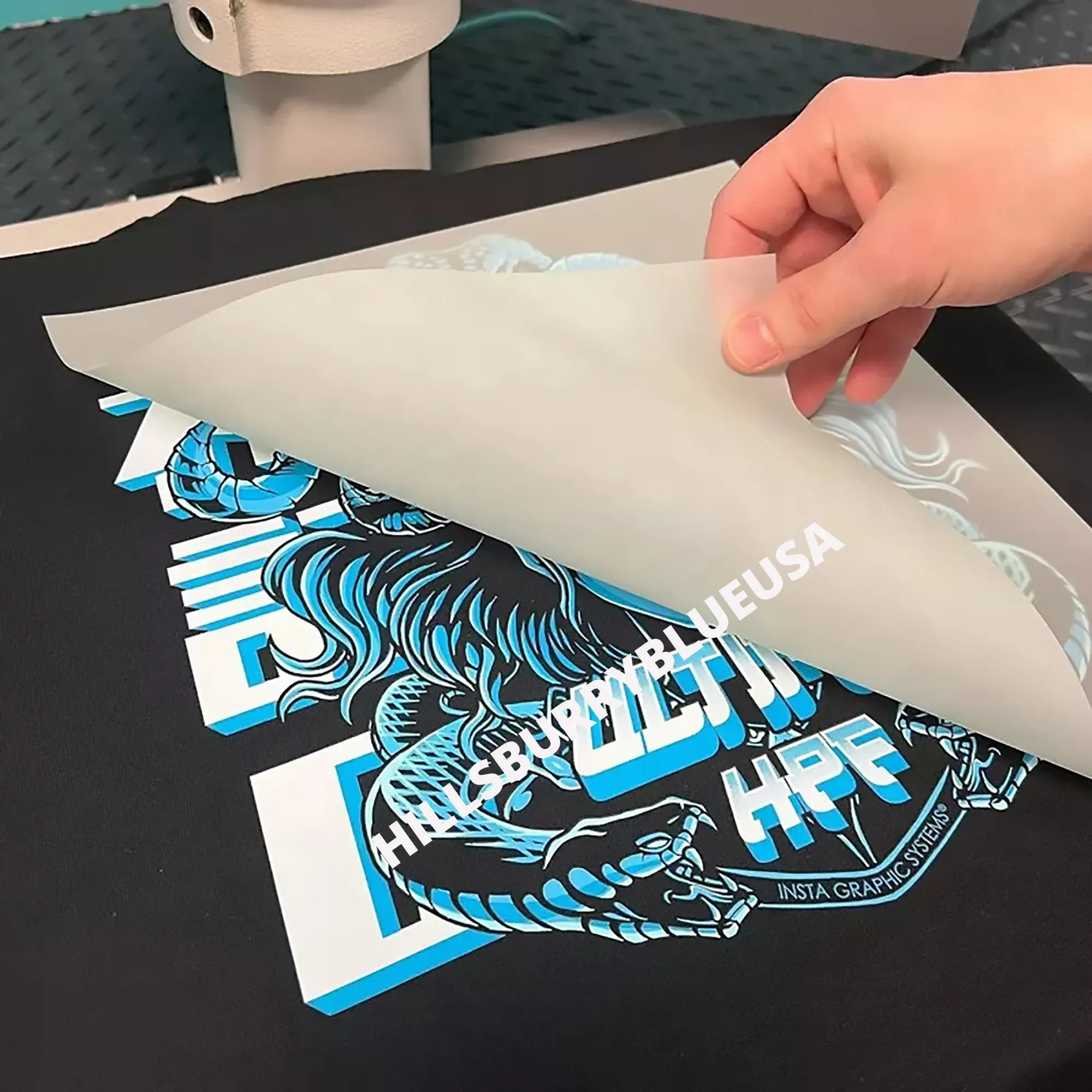

Viewed through an LSI lens, this process is a film-based transfer system where an inked design is printed onto a clear sheet, powder-coated, and cured before being applied to fabric. It serves as a flexible alternative to traditional screen printing, well-suited for short runs, design changes, and on-demand branding. For Texas shops, success hinges on a reliable Direct-to-film setup Texas, steady Texas DTF printing supplies, and smooth workflows that minimize downtime. Practical tips include color management with ICC profiles, thorough prepress checks, and clear care instructions to customers. By embracing these related concepts, brands can build a scalable on-demand apparel operation that thrives in Texas markets.

Texas DTF for Small Businesses: Practical Setup and Scalable Workflows

Texas DTF for small businesses thrives on on-demand production, enabling brands to launch limited runs and fast-turnaround drops without the heavy upfront investments typical of traditional printing. This model lines up with Texas’s dynamic markets in Dallas, Houston, Austin, and San Antonio, where local branding and pop-up events create demand for high-quality, customized apparel. DTF printing Texas delivers vibrant color, sharp detail, and versatility across fabrics, making it a compelling path for entrepreneurs and startups alike, supporting quick test runs and lean inventories. It also reinforces the idea of Texas DTF for small businesses by reducing risk as you scale.

A practical Direct-to-film setup Texas should balance footprint, safety, and performance. Select a printer capable of white ink for light fabrics, a reliable heat press, and a resilient supply chain for DTF film and adhesive powder. Design a compact, well-ventilated workflow that fits in typical Texas workspaces while staying compliant with safety guidelines and local regulations.

Plan a scalable workflow: define your product scope, manage color with ICC profiles, and run test prints on common Texas fabrics such as cotton and cotton blends. Sourcing Texas DTF printing supplies from regional distributors minimizes downtime and shipping costs, while building a local supplier network improves service continuity, troubleshooting, and long-term support.

DTF Printing Tips and Supply Chain Optimization in Texas

DTF printing tips start with solid design and color management. Create artwork at the target print size, use consistent color palettes, and run test prints on typical Texas fabrics to dial in color fidelity and opacity, especially when printing on dark garments that require a white underbase.

In Texas, maintaining a resilient supply chain is essential. Partner with local or regional Texas DTF printing supplies distributors to shorten lead times, reduce stockouts, and simplify returns. Evaluate film quality, adhesive powders, curing equipment, and routine maintenance to keep transfers reliable across seasons.

Beyond production, optimize profitability with transparent costing and targeted marketing. Track material costs per unit, labor, overhead, and depreciation; offer bundled services for events or team pride orders; and leverage local branding to grow revenue in Texas. Applying these DTF printing tips alongside dependable supplies helps Texas-based shops deliver high-quality prints while building repeat business.

Frequently Asked Questions

How does Texas DTF benefit small businesses, and what should you know about DTF printing Texas?

Texas DTF refers to direct-to-film printing used by small businesses across Texas. It enables short-run, customization-friendly production with lower upfront costs than traditional methods like screen printing. For DTF printing Texas, you’ll print onto a transfer film, apply a bonding powder, cure, and transfer with a heat press, delivering vibrant colors on cotton, blends, and more. Key advantages for Texas DTF for small businesses include fast turnaround for local events, event merch, and lean inventory. To start, partner with reliable Texas DTF printing supplies, set up a fit-for-purpose workflow (printer with white ink, RIP, heat press), and follow DTF printing tips such as color management, test prints on representative fabrics, and proper curing. This keeps quality high and profitability achievable.

What is involved in a Direct-to-film setup Texas for a small shop, and how do Texas DTF printing supplies fit into the plan?

A Direct-to-film setup Texas starts with defining your production scope and workspace, then selecting a fit-for-purpose DTF printer with white ink capability, compatible RIP software, DTF film and adhesive powder, a curing unit, and a dependable heat press. In Texas, also account for space, ventilation, and local regulations, and plan around Texas DTF printing supplies availability for quick restocks. Budget for ongoing material costs and maintenance. Practical DTF printing tips include color management with ICC profiles, running test prints on representative fabrics, even powder application, and optimized curing times. With reliable Texas DTF printing supplies and a streamlined workflow, you can scale production while maintaining quality and safety.

| Topic | Key Points |

|---|---|

| What is DTF printing? | DTF uses a special film, colored inks, bonding powder, curing, and heat transfer to fabrics. Benefits include vibrant color, fine detail, and compatibility with cotton, blends, and some synthetics. |

| Why Texas matters | Texas small businesses benefit from short runs, low upfront costs, fast turnarounds, and strong local branding opportunities. Local markets (Dallas, Houston, Austin, San Antonio) and events demand on‑demand production. |

| Key considerations for Texas DTF | Assess market demand and design versatility; plan for a compact, compliant workspace; ensure reliable local suppliers; develop a clear cost and pricing strategy. |

| Setup blueprint: Scope and products | Define products (T‑shirts, hoodies, totes, caps), fabrics (cotton, blends, certain poly blends), minimum orders, color ranges, and supported print sizes. |

| Setup blueprint: Equipment | Choose a DTF printer with white ink capability, compatible film, bonding powder, a curing unit, and a robust heat press. Prioritize local support and workflow flexibility. |

| Workflow from design to transfer | Design for target print size; manage color with ICC profiles; prepress with bleed/timing; print on film, powder and cure; transfer to fabric with heat press; provide care instructions for longevity. |

| Quality control | Maintain color consistency across batches; check alignment; verify white ink opacity on dark fabrics; ensure proper curing and powder adhesion; note substrate limitations. |

| Cost control and profitability | Track material costs per unit, labor time, and overhead; price strategically; use bundles and add‑on services to raise average order value. |

| Marketing and growth in Texas | Leverage local collaborations, events, and e‑commerce; showcase behind‑the‑scenes content and testimonials; design packaging that reinforces brand quality. |

| Safety, compliance, and sustainability in Texas | Maintain proper ventilation and safety practices; stay compliant with regulations; explore eco‑friendly film/adhesives and disclose sustainability efforts. |

| Practical Texas case example | A Texas shop shifts to on‑demand DTF for local events, reduces lead times, sources regionally, adjusts pricing for variable fabric costs, and sees higher order values and faster turnover. |