Texas DTF Printing: A Beginner’s Ultimate Guide to Direct-to-Film

Texas DTF Printing has surged in popularity as a versatile and beginner-friendly method for creating vibrant, long-lasting custom apparel. If you are exploring Direct-to-Film printing, this introductory guide for DTF printing for beginners explains what the process is, why it appeals to newcomers, and how to get started with confidence. In this overview, you will learn how DTF transfer process works, why it suits beginners, and how to choose the right printer, film, and ink. You will also see practical tips for working with DTF inks and DTF fabrics to achieve bold colors and durable finishes. By following the workflow outlined here, Texans and others can start a successful DTF project lineup with confidence.

Alternative terms for this approach include film-to-fabric transfer and a modern print-on-film workflow, which align with the broader field of digital garment decoration. In practice, the process uses a coated transfer film, color inks, adhesive powder, and a heat press to move vibrant designs onto textiles. This technology shares roots with other on-demand apparel methods but emphasizes color fidelity, soft hand, and effective results on dark fabrics through a white underbase when needed. For beginners exploring this path, the focus is on repeatable steps, reliable supplies, and clear testing on similar fabrics before committing to runs.

Frequently Asked Questions

What is the DTF transfer process in Texas DTF Printing and why is it beginner-friendly?

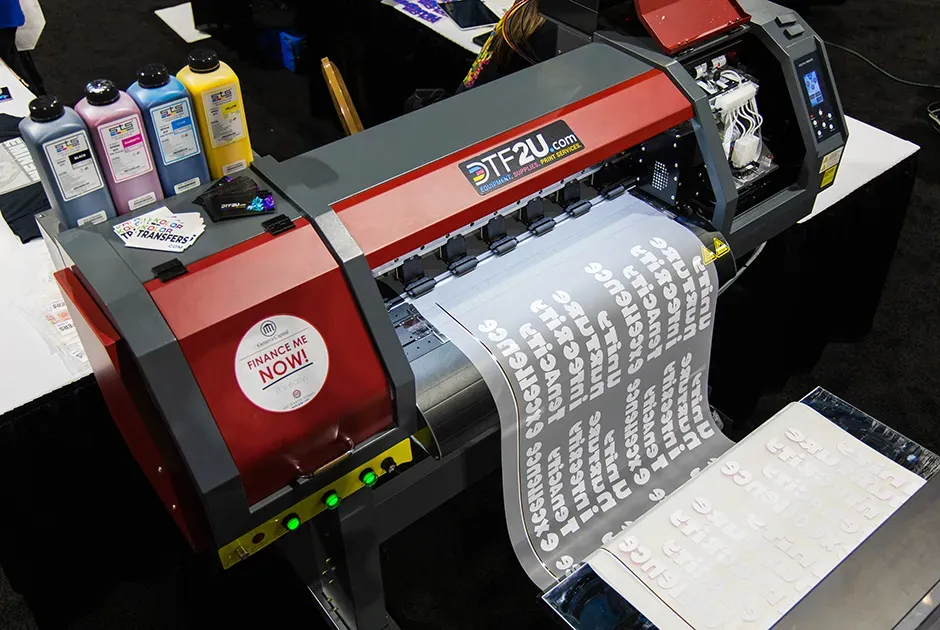

Texas DTF Printing uses a Direct-To-Film transfer to create vibrant, durable apparel designs. The DTF transfer process normally involves printing the design onto a PET transfer film with CMYK plus white inks, applying adhesive powder, curing, and heat-pressing the film onto fabric. This beginner-friendly workflow offers strong color reproduction and broad fabric compatibility (cotton, polyester, blends), making it a practical option for newcomers aiming to produce professional-looking prints for Texas teams, schools, and events.

Which fabrics and inks are best for Texas DTF Printing, and how should beginners manage DTF inks and fabrics?

For Texas DTF Printing, use DTF inks (CMYK plus white) to achieve opacity on dark fabrics and bright color on light fabrics. Start with common DTF fabrics like 100% cotton or cotton-poly blends and test on representative swatches before full runs. Calibrate your printer regularly, use a quality transfer film and adhesive powder, and apply a white underbase on darker fabrics to maintain color accuracy. With careful testing, you can achieve consistent results across various DTF fabrics.

| Topic | Key Points |

|---|---|

| What is Direct-To-Film (DTF) Printing? | Printed onto a transfer film using CMYK plus white; adhesive powder is applied and cured; the transfer is heat-pressed onto fabric; results are vibrant, durable, and compatible with cotton, polyester, blends; beginner-friendly. |

| Why Texas DTF Printing is Gaining Traction | Great for short runs, events, schools, and merchandise; favorable price-to-performance; strong color accuracy on light, dark, and solid fabrics; aligns with Texas teams, clubs, and brands. |

| Key Equipment and Supplies for DTF Printing | DTF printer with CMYK+white ink; PET transfer film; powder adhesive and curing system; heat press; heat-resistant workstation; PPE; reliable ink supply. |

| Choosing the Right Setup for Texas DTF Printing | Budget-conscious; matches production volume and print quality; start small or with used printer; upgrade later for throughput. |

| Understanding the DTF Printing Process (Design to Transfer) | Design with color management; print on film with white base; apply adhesive powder and cure; transfer with heat press at ~160–170°C (320–340°F) for 15–20s; cool and peel; optional finishing press. |

| DTF Inks and Color Management | CMYK plus white; calibrate printer; run test prints; maintain ink density and consistent curing and transfer temperatures; tailor profiles for common Texas fabrics. |

| DTF Fabrics and Material Compatibility | Works on cotton, polyester, blends; fabric texture and fiber affect outcome; test on swatches; use white underbase for dark fabrics. |

| Troubleshooting Common DTF Issues | Faded colors: adjust ink density and white underbase; adhesion issues: ensure powder curing and correct temperature/pressure; gaps: check alignment; cracking: appropriate film and heat; misregistration: use jig. |

| Care, Maintenance, and Best Practices | Clean print heads; store inks properly; use quality films and powders; check heat press evenness; regular test prints. |

| DTF Transfer Process vs. Other Methods | DTF offers color fidelity and durability; often easier than some vinyl or DTG; good on dark fabrics due to white underbase; lower pretreat needs than DTG. |

| Caring for DTF Prints and Longevity | Wash inside-out in cold or warm water; mild detergents; avoid bleach; low-heat drying; avoid direct sunlight. |

| Cost Considerations, ROI, and Getting Started in Texas | Upfront costs include printer with white ink, heat press, films, consumables; target small runs, schools, clubs; scalable margins with smart budgeting. |

| Practical Tips for Aspirants: Your First 10 Projects | Bold colors and clean lines; test swatches; create a quick-order catalog; document workflow; seek feedback. |

| Next Steps and Resources | Join local maker groups, attend printing meetups, explore online courses, connect with Texas suppliers for materials and shipping. |

Summary

Texas DTF Printing has emerged as a practical, scalable option for beginners and growing shops alike. This overview highlights how DTF works, why it fits Texas markets, the essential gear, and practical steps to start your own Texas DTF Printing journey with confidence. By mastering the DTF workflow—from design to transfer to care—you can produce vibrant, durable prints on a variety of fabrics while optimizing cost and turnaround. Whether you’re serving schools, clubs, or local brands, the Texas DTF Printing path offers a repeatable, approachable route to growing an on-demand apparel business.