UV DTF Gangheet: Revolutionizing Fashion and Design

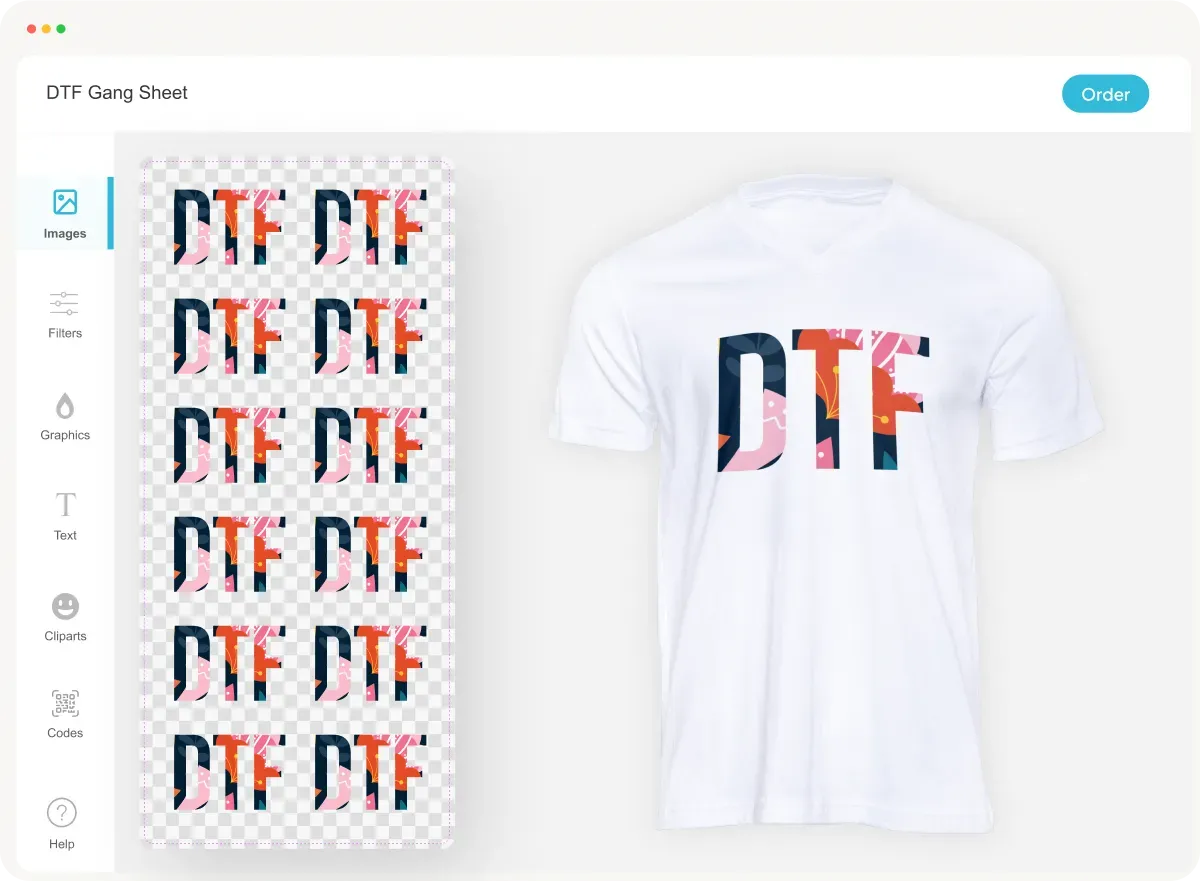

In the ever-evolving world of fashion design, **UV DTF gangheet** stands out as a groundbreaking innovation. This unique technique, which integrates Direct to Film printing with cutting-edge UV curing technology, has transformed the way custom apparel is produced. Designers are now able to create intricate, vibrant designs that are not only visually stunning but also enduring, thanks to the immediate curing capabilities of UV inks. As sustainability becomes a focal point in modern fashion, UV DTF provides an eco-friendly alternative that meets consumer demands for responsible production. Let’s explore the myriad benefits and applications of UV DTF gangheet and its impact on the future of fashion.

The rise of **ultraviolet Direct to Film printing** has revolutionized the landscape of custom fabric printing, bringing about a host of exciting advancements. This method combines the precision of direct printing with the speedy and effective curing process facilitated by ultraviolet light. As brands increasingly prioritize sustainable fashion choices, this innovative technique aligns perfectly with the shift towards eco-conscious production practices. Moreover, UV printing technology not only enhances the quality of designs but also empowers designers to stay ahead of fashion design trends with its quick turnaround times. Embracing these advancements, the fashion industry is on the brink of a creative renaissance driven by versatile and sustainable printing solutions.

Understanding UV DTF Printing Technology

UV DTF (Direct to Film) printing technology is an innovative process that merges traditional printing techniques with cutting-edge ultraviolet curing methods. This process facilitates vibrant color application on films that retains its integrity under various conditions. By utilizing UV inks that cure instantly upon exposure to UV light, designers are able to create high-quality images and patterns that are both detailed and durable. This immediacy in finishing enhances workflow efficiency, setting UV DTF apart from conventional methods that often require extended drying times.

The UV DTF process is particularly advantageous for fashion designers exploring intricate designs. Unlike traditional inks that may smudge or fade, the UV-curing technology ensures long-lasting prints that maintain their vibrancy over time. This appeals not only to designers but also to brands committed to producing high-quality, custom apparel that meets consumer expectations. As brands continue to seek innovative approaches to stand out in this competitive landscape, the integration of UV DTF offers a unique solution in elevating design quality and practicality.

Applications of UV DTF in Custom Apparel

The landscape of custom apparel has evolved dramatically with the advent of UV DTF printing technology. Brands are no longer limited to simple designs; they can now offer personalized clothing items that showcase intricate art and unique patterns. This method enables the creation of custom t-shirts, hoodies, and even accessories on-demand, addressing the growing consumer inclination for tailor-made products. The efficiency of the UV DTF process ensures that production can keep up with fashion trends while catering to diverse customer preferences.

Beyond aesthetics, the durability of UV DTF prints allows for frequent washing and wearing without compromising quality. This reliability means customers can enjoy their unique apparel longer, promoting repeat business for brands. Additionally, as customization continues to dominate market trends, the adaptability of UV DTF printing empowers designers to quickly respond to consumer demands for new designs, making it an essential tool in modern fashion manufacturing.

Sustainability in Fashion Through UV DTF

Sustainability has emerged as a vital focal point in the fashion industry, and UV DTF printing stands at the forefront of this movement. By utilizing eco-friendly, water-based inks that are free from hazardous solvents, UV DTF significantly reduces the environmental impact compared to traditional printing methods. As more consumers seek sustainable fashion options, brands that adopt UV DTF print processes can align themselves with ethical practices, thereby enhancing their market appeal.

Moreover, the efficiency of UV DTF technology helps minimize waste, as it allows for precise printing without the need for excess materials. This aligns with the increasing consumer preference for brands that prioritize sustainability without compromising quality or design. By investing in UV DTF printing technology, brands can not only contribute positively to the environment but also gain a competitive edge in a landscape where conscious consumerism is on the rise.

Impact of UV DTF on Fashion Design Trends

The introduction of UV DTF printing technology has transformed fashion design, offering revolutionary opportunities for creativity and expression. Designers can now push the boundaries of traditional garment printing, producing intricate and complex designs with unparalleled precision. This freedom allows for artistic experimentation, encouraging a diverse range of styles that reflect contemporary fashion design trends.

As a result, fashion shows and collections can now incorporate bold graphic designs and multi-dimensional textures that were previously difficult to achieve. This transformation not only enriches the visual landscape of fashion but also inspires a new generation of designers to explore innovative ideas, forging a pathway toward uniquely creative apparel that resonates with diverse consumer tastes.

Economic Growth Driven by UV DTF Technology

The economic implications of UV DTF printing technology are significant, particularly as demand for custom apparel and personalized items continues to rise. With market research indicating robust growth projections for UV DTF, brands that incorporate this technology position themselves to capitalize on burgeoning consumer preferences for uniqueness and individuality. As more small businesses and independent designers adopt UV DTF methods, the overall economic landscape of the fashion industry is evolving.

Furthermore, ongoing advancements in UV ink formulations and printing technology make UV DTF more accessible and affordable for smaller enterprises. This democratization of advanced printing methods empowers emerging fashion brands to compete on equal footing with established players, fueling innovation and diversification within the market. As the accessibility of UV DTF expands, so does the potential for economic growth within the fashion and design sectors.

The Future of Fashion with UV DTF

Looking ahead, UV DTF printing technology appears to be a game-changer for the fashion industry. As brands continue to evolve in response to consumer demands for sustainability, customization, and speed, the integration of UV DTF could very well set the standard for future apparel production. With the ability to produce high-quality, durable designs swiftly, this technology allows for an agile response to ever-changing fashion trends and market needs.

Additionally, as more brands recognize the potential of UV DTF, collaborative efforts between manufacturers, designers, and environmental advocates may emerge, fostering a more sustainable future for fashion. The ongoing development and refinement of UV DTF technology will likely pave the way for new artistic and commercial possibilities, ultimately shaping the evolution of fashion in the years to come.

Frequently Asked Questions

What benefits does UV DTF gangheet offer for custom apparel design?

UV DTF gangheet provides several advantages for custom apparel design, including vibrant color quality and durability. The advanced UV printing technology allows for intricate designs that maintain their integrity even after multiple washes. Moreover, the ability to print on-demand makes it easier for brands to cater to unique consumer preferences, aligning with current fashion design trends.

How does UV DTF printing technology contribute to sustainable fashion?

UV DTF printing technology contributes to sustainable fashion by utilizing eco-friendly inks that are often water-based and free from harmful solvents. This process significantly reduces waste and the environmental impact typically associated with traditional screen printing methods. Brands adopting UV DTF gangheet can enhance their commitment to sustainability while meeting consumer demands for responsible production.

Can UV DTF gangster print on materials other than fabric?

Yes, UV DTF gangheet can print on a variety of materials beyond fabric, including leather, plastics, and even wood. This versatility in printing opens up new possibilities for fashion designers, allowing them to create unique, multi-material custom apparel that aligns with contemporary design trends.

What role does UV DTF gangheet play in rapid fashion production?

UV DTF gangheet plays a crucial role in rapid fashion production by significantly reducing turnaround times for custom pieces. The instant curing of UV inks allows for quick production, enabling brands to respond swiftly to changing trends and consumer demands in the fast-paced fashion industry.

Why is UV DTF considered a game-changer for the fashion industry?

UV DTF is considered a game-changer for the fashion industry due to its ability to produce high-quality, customizable prints rapidly and sustainably. This technology supports the growing trend towards personalized items and sustainable practices, enabling designers to leverage the latest innovations in UV printing technology for their fashion design projects.

How is UV DTF gangheet influencing design creativity?

UV DTF gangheet is influencing design creativity by enabling designers to produce complex and intricate designs with precision. The technology expands the creative possibilities in fashion, allowing for artistic expressions that were previously difficult to achieve with traditional printing methods. This innovation fosters a new wave of creativity in the fashion design industry.

| Key Point | Description |

|---|---|

| What is UV DTF? | UV DTF, or Direct to Film, combines digital printing with UV ink curing for instant-drying, vibrant prints. |

| Applications in Fashion | Custom apparel, sustainability, and speed in production are key areas where UV DTF is making an impact. |

| Impact on Design | Allows complex designs and textile innovation across diverse materials beyond fabric. |

| Market Trends | Growing demand for custom apparel and advancements in technology signal positive trends for UV DTF. |

Summary

UV DTF gangheet represents a groundbreaking shift in the fashion and design industries, revolutionizing the way custom apparel is created. This innovative printing technology allows for on-demand production, enhances sustainability practices, and supports intricate design possibilities across diverse materials. The increasing consumer demand for unique, quality items has propelled UV DTF to the forefront of market trends, ensuring its significance in shaping the future of fashion. As brands continue to adopt this methodology, they position themselves advantageously in an evolving landscape that prioritizes efficiency, eco-friendliness, and creative expression.