UV DTF Gangheet: Your Guide to High-Quality Printing

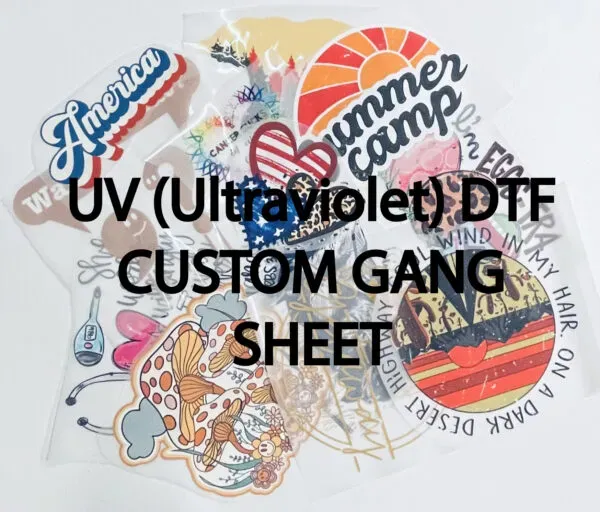

UV DTF Gangheet is revolutionizing the printing landscape by seamlessly blending cutting-edge UV printing technology with versatile Direct to Film printing techniques. This innovative approach allows for high-quality printing on a variety of materials, transforming standard substrates into vibrant canvas for artistic expression. With its capability to deliver stunning visual results, UV DTF Gangheet is becoming the go-to method for businesses seeking to make their products stand out in a saturated market. Additionally, this sustainable printing solution minimizes waste while maximizing efficiency, making it an environmentally friendly choice. As the demand for customizability and durability grows, industries are increasingly tapping into the potential of UV DTF applications, ensuring their offerings remain competitive and relevant.

The emergence of Direct to Film gangheet printing is heralding a new era in high-quality print production. By utilizing state-of-the-art ultraviolet technology, this method allows for exceptional color vibrancy and precision on various substrates, making it a popular choice across multiple sectors. This innovative process, often termed as UV DTF printing, emphasizes sustainability and efficiency, appealing to modern businesses that prioritize eco-friendly practices. With a wide range of applications available, from personalized merchandise to striking signage, Direct to Film techniques are reshaping consumer expectations and experiences. As industries continue to explore the possibilities of this advanced printing method, the focus remains on delivering unparalleled quality and durability.

Understanding UV Printing Technology

UV printing technology utilizes ultraviolet light to cure or dry inks as they are printed. This innovative process starts by applying UV-sensitive inks onto various substrates, and as the print head moves, UV light immediately solidifies the ink, leading to sharp images and vibrant colors. Because of this rapid curing process, UV printing allows for greater flexibility in terms of materials, with no drying time required, making it particularly advantageous for businesses needing quick turnaround times.

The fundamental aspects of UV printing make it a suitable choice for various industries, from packaging to signage and textiles. UV inks can be applied to surfaces that traditional inks might struggle to adhere to, such as metals, plastics, and even uneven surfaces. As a result, businesses have the opportunity to explore a broader range of creative applications that would have been impossible with older printing methods.

Exploring UV DTF Applications

UV DTF printing offers remarkable versatility across various sectors. In the fashion and apparel industry, designers can create unique prints that showcase intricate details and vibrant colors on textiles. The technique allows for personalization, catering to the growing consumer demand for custom-designed garments that reflect individual style and preferences.

Moreover, the graphic and signage industries have also embraced UV DTF applications. The ability to produce eye-catching promotional materials and durable signage that withstand the elements has proven invaluable for marketing efforts. With UV DTF, businesses can achieve bold and striking displays that not only attract attention but also enhance brand visibility.

The Advantages of UV DTF Printing

One of the primary advantages of UV DTF printing is the exceptional quality it delivers. The combination of vibrant colors and precise details enables clients to produce high-quality prints that can elevate product appeal. This technology is especially beneficial for businesses that rely on striking visuals to capture consumer interest, such as those in fashion or interactive marketing.

Additionally, durability is a significant selling point. UV DTF prints are resistant to scratching, fading, and water damage, making them ideal for applications where longevity is critical. This enhanced durability ensures that printed items maintain their vibrant appearance even after prolonged exposure to outdoor conditions or frequent handling.

Sustainability in UV DTF Printing

With growing awareness about environmental issues, sustainable printing practices have taken center stage, and UV DTF printing aligns well with these ideals. Compared to traditional methods, UV DTF technology results in less waste due to the immediate curing of inks and the ability to print on demand. This efficiency not only reduces environmental impact but also streamlines production processes for companies.

Moreover, many manufacturers are currently developing eco-friendly inks and substrates compatible with UV DTF printing, further enhancing the sustainability aspect. By choosing such innovative solutions, businesses can contribute to a greener planet while still meeting consumer demands for high-quality products.

Market Trends in UV DTF Printing

The demand for UV DTF printing is expected to surge as digital printing technologies evolve. Industry trends indicate a movement towards customization, with consumers seeking unique products tailored to their preferences. This shift means that businesses must adopt advanced printing technologies, such as UV DTF, to stay competitive. The capacity to deliver personalized prints quickly and efficiently gives brands a distinct advantage in a crowded market.

Furthermore, the integration of UV DTF printing with e-commerce is becoming increasingly prevalent. Online retailers are leveraging this technology to fulfill personalized orders in a timely manner, accommodating the growing trend of custom products. As e-commerce continues to dominate the retail landscape, businesses that incorporate UV DTF printing will likely find themselves at the forefront of customer satisfaction.

Recent Innovations in UV DTF Technology

Innovations within the UV DTFprinting sector have significantly enhanced print quality and usability. Manufacturers are continually experimenting with advanced ink formulations that improve adhesion and color vibrancy, ensuring that prints remain consistently high quality. This proactive development enables businesses to produce more refined and appealing products, broadening the market appeal.

Additionally, advancements in printing machinery and processes are making UV DTF printing more accessible to a wider range of users, from small businesses to large manufacturers. These improvements are setting new standards for efficiency and quality in the printing industry.

Frequently Asked Questions

What are the key benefits of using UV DTF Gangheet for high-quality printing?

UV DTF Gangheet offers numerous benefits, including vibrant colors, sharp details, and durability. The UV printing technology ensures that prints are resistant to fading and scratches, making them ideal for various applications such as garments and promotional materials.

How does UV DTF Gangheet differ from traditional printing methods?

Unlike traditional printing methods, UV DTF Gangheet utilizes Direct to Film printing technology, allowing for a more versatile approach. It can print on a wide range of substrates while maintaining high print quality and reducing waste, aligning with sustainable printing practices.

What types of substrates can be used with UV DTF Gangheet?

UV DTF Gangheet is incredibly versatile, enabling high-quality printing on various substrates such as textiles, glass, wood, and plastic. This adaptability makes it suitable for a diverse range of UV DTF applications from fashion to interior design.

Are there any recent innovations in UV DTF Gangheet technology?

Yes, recent developments in UV DTF Gangheet technology include innovative ink formulations that enhance color range and adhesion. Such advancements improve print quality and open new possibilities for customization in the printing industry.

How does UV DTF Gangheet support sustainable printing practices?

UV DTF Gangheet promotes sustainable printing by offering faster turnaround times and reducing waste in the printing process. This efficiency, combined with high-quality output, caters to the growing demand for eco-friendly solutions in the industry.

What industries can benefit from using UV DTF Gangheet?

Various industries can benefit from UV DTF Gangheet, including fashion and apparel for custom garment printing, signage and marketing for promotional materials, and personalized consumer products like phone cases and home decor, making it a valuable asset across sectors.

| Key Points | Details |

|---|---|

| What is UV DTF Printing? | UV DTF printing combines UV printing and Direct to Film technology for high-quality prints on various substrates. |

| Advantages of UV DTF Printing | 1. Vibrant Colors and Sharp Details: Produces rich colors and high-definition details. 2. Durability: Resistant to fading, scratches, and water. 3. Versatility: Suitable for textiles, wood, glass, and plastic. |

| Recent Developments | 1. Innovative Ink Formulations: Improved adhesion and color range. 2. Growing Demand: Increasing customization driving market growth. |

| Market Trends | 1. Sustainable Practices: Faster turnarounds and less waste. 2. Integration with E-commerce: Efficient production for customized items. |

| Applications | 1. Fashion and Apparel: High-quality custom garment printing. 2. Signage and Marketing: Bold promotional materials. 3. Personalized Consumer Products: Customization of various goods. |

Summary

UV DTF Gangheet is revolutionizing the way products are printed, offering businesses the ability to create stunning, high-quality prints with remarkable durability and versatility. This innovative printing method combines the strengths of ultraviolet printing and Direct to Film technology, enabling prints on a wide range of materials from textiles to plastics. As industries increasingly prioritize sustainability and customization, UV DTF Gangheet stands out as a leading solution, ensuring that businesses can meet modern consumer demands while enhancing their brand identity. Keeping abreast of advancements in UV DTF printing will not only equip businesses with the tools they need to succeed but also pave the way for future innovations in the printing space.