DTF Transfers: A Beginner’s Guide to Mastering Techniques

DTF Transfers, or Direct to Film transfers, are revolutionizing the textile printing industry with their remarkable ability to deliver striking and detailed designs on a wide range of fabrics. As a relatively modern printing approach, DTF integrates traditional methods with cutting-edge DTF transfer technology, making it accessible for novices and experienced printers alike. Mastering DTF transfers opens up a world of creative possibilities, and our beginner’s guide will equip you with essential knowledge on effective printing techniques, the necessary DTF printing equipment, and best practices for DTF. By understanding this dynamic technique, you can achieve high-quality results that resonate with consumers looking for unique custom apparel and promotional items. Embrace the artistry of DTF printing and discover how it can enhance your craft and business ventures, turning every fabric into a canvas of potential.

Exploring the realm of Direct to Film printing offers a fresh perspective on modern printing aesthetics and techniques. Known for its dynamic versatility, the DTF transfer method emphasizes the harmonious blend of innovative print technologies and traditional applications, allowing for creative freedom that few other methods can rival. Often referred to as DTF printing, this approach involves both advanced machinery and a careful understanding of print materials and techniques, ultimately resulting in durable and vibrant printed designs. Those interested in custom prints will benefit from grasping the fundamental aspects of this method, as well as the equipment needed and best practices for achieving superior results. As trends continue to evolve, the insights and knowledge gained can empower individuals to push the boundaries of fabric printing.

The Basics of Direct to Film (DTF) Printing

Direct to Film (DTF) printing represents a groundbreaking approach in the fabric printing arena, merging innovative technology with traditional methods. This technique allows printers to transfer intricate designs from a specially coated film directly onto textiles, ensuring vibrant colors and exceptional detail. One of its main advantages is the ability to print on various fabric types, including cotton, polyester, and even blends, thereby catering to a wide array of applications from fashion to promotions.

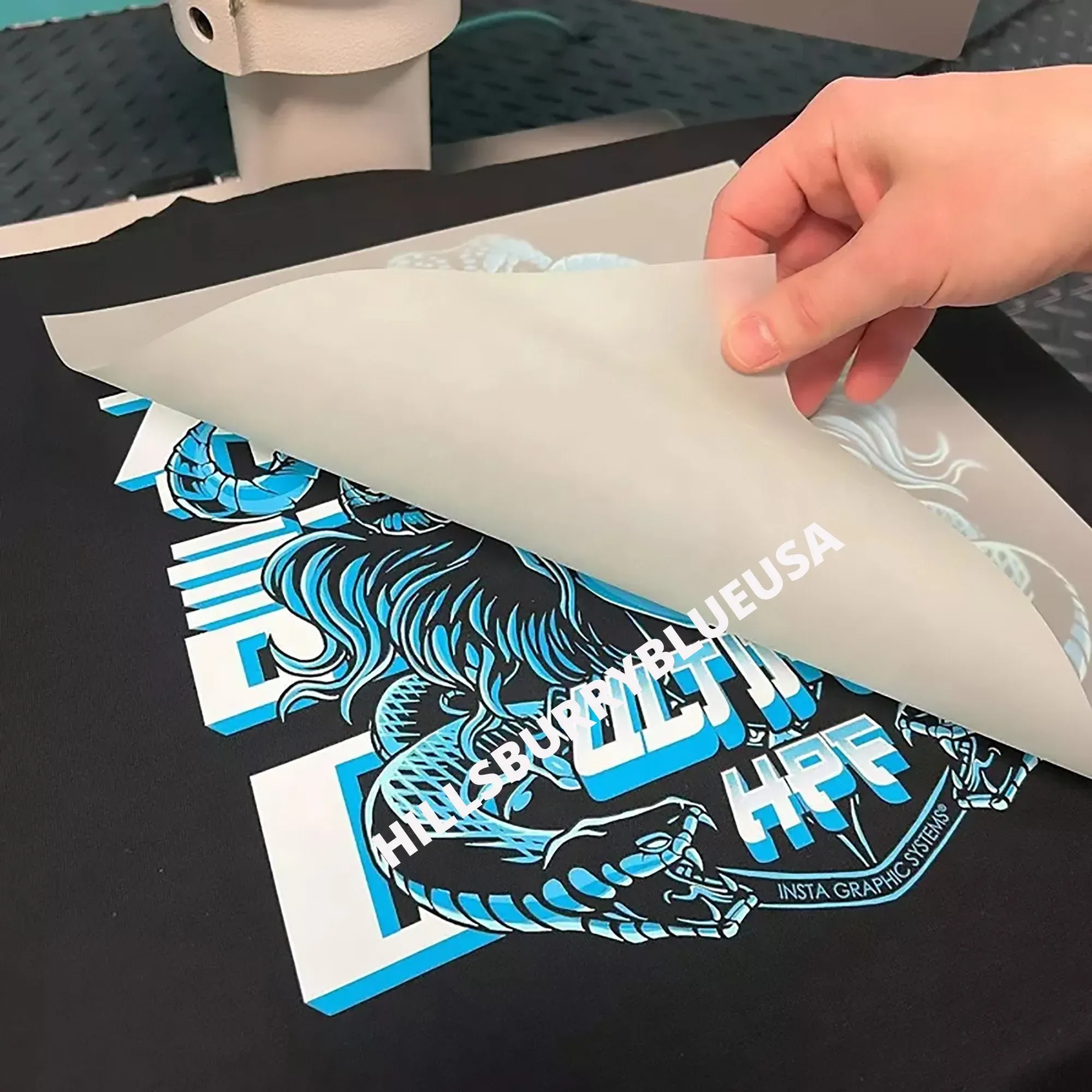

Understanding the DTF process involves several crucial steps: creating a design, printing onto a PET film with specialized inks, applying adhesive powder, and heat transferring to the fabric. Each phase is integral to achieving a durable and high-quality print. As the popularity of this method expands, more users are tuning into the nuances of DTF printing, exploring its various techniques and best practices for flawless results.

Essential Equipment for Successful DTF Transfers

To embark on your DTF printing journey, having the appropriate equipment is paramount. The core component, the DTF printer, must be capable of handling PET film and utilizing compatible inks, which are essential for vibrant and lasting prints. Many users prefer modified inkjet printers, particularly those from Epson, known for their color accuracy and reliability. A well-chosen printer is the first step towards successful DTF transfers.

In addition to a reliable printer, a quality heat press is indispensable for the DTF process. This machine must be adjustable to achieve the right temperature and pressure for optimal transfer results. Compatibility with various fabric types and the ability to apply consistent heat are crucial features. Remember, the right equipment not only enhances print quality but also streamlines the production process, making it easier to meet client demands.

Mastering DTF Printing Techniques

Understanding best practices for DTF printing can significantly influence the quality of your output. One crucial technique involves pre-setting your printer with the correct specifications, such as color modes and DPI settings. Each design might require adjustments for optimal results, so thorough testing on varying fabric types and colors is recommended to fine-tune your printing process and ensure consistency.

Another essential aspect of mastering DTF transfers is the proper application of adhesive powder. This step is critical as it ensures that the printed design adheres securely to the fabric during the transfer process. Apply the powder evenly and remember to cure it adequately before pressing, as improper adhesion can lead to design failures or reduced durability of your prints. Following these techniques will help elevate your DTF printing expertise.

Understanding the Advantages of DTF Transfers

DTF transfers offer numerous advantages over traditional printing methods, making them a favorite in modern textile applications. One of the most significant benefits is their versatility, allowing the use of various textiles without compromising print quality. This adaptability makes DTF transfers the perfect choice for custom apparel, promotional products, and specialty items.

In addition to versatility, DTF transfers are known for their durability. The prints are less likely to fade or peel, even after numerous washes and wear, ensuring your designs remain vibrant over time. The ability to print small batches without expensive set minimums makes DTF a cost-effective solution, particularly for startups and businesses aiming to reduce inventory risks.

Best Practices for DTF Printing Success

To excel in DTF printing, adopting best practices is essential for achieving optimal results. Begin by selecting high-quality materials, including premium PET films and eco-friendly inks, which significantly enhance the durability and vibrancy of the final product. Regularly calibrating your printer ensures precise color reproduction and reduces the risk of pixelation in intricate designs.

Furthermore, maintaining your printing equipment plays a vital role in successful DTF operations. Regular cleaning of print heads and proper storage of materials can prevent common printing issues, including clogs and inconsistencies. Establishing a routine for equipment maintenance will not only extend the life of your printer and heat press but also guarantee that your prints maintain high standards.

Future Trends in DTF Printing and Technology

The landscape of DTF printing is experiencing rapid evolution, with advancements aimed at improving print quality, speed, and sustainability. One emerging trend is the development of more efficient printing equipment that allows for quicker turnarounds on larger orders, essential for businesses targeting high-volume production. Innovations in ink formulations are also paving the way for more environmentally friendly options, catering to a growing demand for sustainable practices within the textile industry.

In addition to technological advancements, educational opportunities are becoming increasingly accessible. Online workshops, tutorials, and community forums are invaluable resources for both novices and experienced printers seeking to refine their skills. Keeping abreast of these developments not only enhances individual capabilities but also equips businesses to stay competitive in this dynamic market, embracing the full potential of DTF transfer technology.

Frequently Asked Questions

What is DTF transfer technology and how does it work?

DTF transfer technology, or Direct to Film printing, involves printing designs onto a PET film using specialized inks. Once printed, the film is coated with a hot-melt adhesive powder that bonds the ink to the fabric when heat is applied, allowing for vibrant and durable designs on textiles.

What are the benefits of using DTF printing equipment for fabric transfers?

Using DTF printing equipment, such as a specialized printer and heat press, offers numerous benefits. These include the ability to print on various fabrics, durability of the transfers, high detail in designs, and lower setup costs compared to traditional printing methods, making it ideal for both small and large production runs.

What are some best practices for DTF transfers to ensure quality results?

To achieve quality results with DTF transfers, it’s essential to use high-quality films and inks, adjust printer settings correctly for the material being printed, and regularly maintain your printing equipment. Testing different settings for various fabrics can also help optimize the transfer’s adherence and color vibrancy.

Can any printer be used for DTF printing or are there specific requirements?

Not any printer will suffice for DTF printing. You need a specialized printer that can handle PET film and is compatible with eco-solvent or water-based inks. While dedicated DTF printers exist, many users successfully adapt standard inkjet printers, notably from brands like Epson, for this purpose.

What are some common mistakes to avoid when using DTF printing techniques?

Common mistakes in DTF printing include improper temperature or pressure settings during the heat transfer, overlooking the need for even adhesive powder distribution, and failing to perform adequate printer maintenance. It’s crucial to read the manufacturer’s guidelines for equipment and film to avoid these pitfalls.

How can I learn more about effective DTF printing techniques?

To enhance your knowledge of DTF printing techniques, consider enrolling in online courses, attending workshops, or browsing through detailed guides and resources available from printing associations. Keeping up with current trends in the DTF printing landscape can also provide valuable insights into improving your skills.

| Topic | Details |

|---|---|

| Introduction | DTF transfers are a modern, versatile method for textile printing, suitable for beginners and professionals. |

| Understanding DTF Printing | Involves high-quality images printed on PET film, transferred using heat, promoting vibrant designs on various fabrics. |

| Advantages of DTF Transfers | Versatile, durable, high-detail, and no minimum orders required. |

| Equipment Needed | Includes a specialized printer, heat press, and adhesive powder. |

| Step-by-Step Process | Design, print, apply adhesive, and transfer to fabric. |

| Best Practices | Use quality materials, test settings, and maintain equipment. |

| Recent Trends | Sustainable practices and educational resources are prominent in DTF printing advancements. |

Summary

DTF Transfers have revolutionized the textile printing industry by providing a method that combines versatility, durability, and high detail in designs. By understanding the process—from selecting the right equipment to following best practices—beginners can confidently engage in DTF printing, exploring new creative horizons. Staying informed about the latest trends will further enhance your ability to thrive in this evolving landscape.