Essential DTF Supplies: What You Need for Quality Printing

Essential DTF supplies are the backbone of high-quality Direct-to-Film printing, an increasingly popular method for creating vibrant designs on textiles. As the demand for custom apparel and promotional products rises, understanding these essential supplies is crucial for both enthusiasts and professionals. This guide will explore key items such as DTF printing equipment, DTF transfer film, and DTF inks that are necessary for a successful printing process. Additionally, we’ll discuss how heat press machines play a pivotal role in ensuring the durability and quality of your prints. Dive into the world of DTF printing to uncover how the right supplies can elevate your creative projects.

In the realm of textile printing, the term Direct-to-Film (DTF) refers to a method that caters to those looking for quality and efficiency when transferring designs onto fabric. To maximize your printing results, one must be familiar with the vital components involved in the process, including the various types of DTF supplies needed. Key items such as specialized printers, transfer films, and eco-friendly inks form the foundation of successful projects. Moreover, using efficient heat application through reliable machines ensures that prints not only look good but also stand the test of time. Join us as we delve deeper into the various supplies that make DTF printing a top choice for customization in the fashion and promotional industries.

Understanding DTF Printing Equipment

To fully appreciate DTF printing, it is crucial to understand the specific equipment used in this innovative process. DTF printers are specially designed to transfer designs onto film, and they operate differently from traditional printers. For instance, brands like Epson and Brother offer impressive models that cater to the unique requirements of DTF printing by utilizing advanced inkjet technology. This equipment can produce highly detailed, vibrant prints that are essential for quality textile applications.

Beyond printers, DTF printing equipment includes essential accessories such as pretreatment machines, heat presses, and curing ovens. Each piece of equipment plays a specific role in the DTF process. Heat presses, for example, are vital for ensuring the correct temperature and pressure are applied during transfer, affecting the durability and quality of the print. Understanding these tools and how they work together is fundamental for both newcomers and seasoned professionals in achieving outstanding results.

The Role of DTF Transfer Film

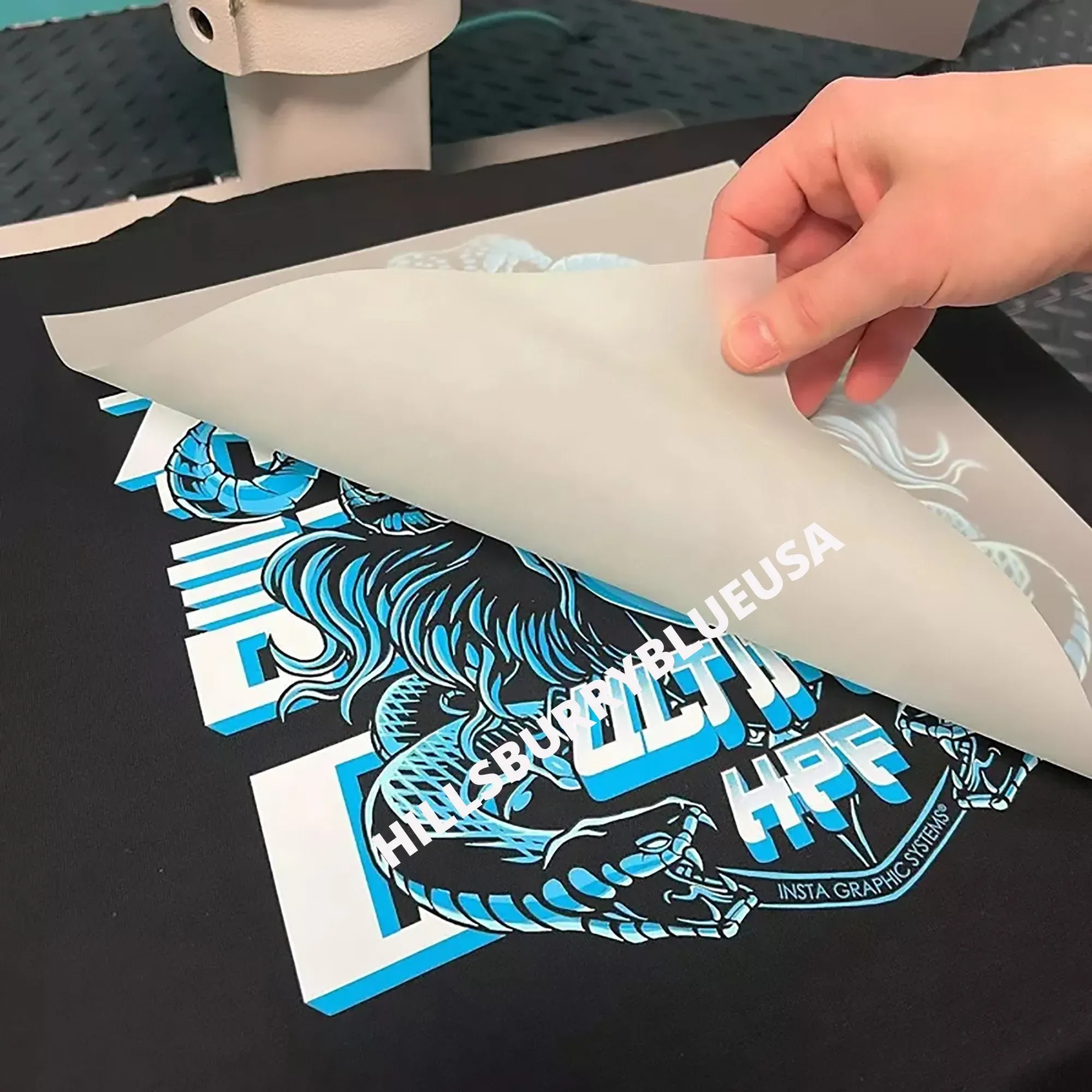

DTF transfer film is a pivotal component in the Direct-to-Film printing process. This specialized film serves as the carrier for your printed designs before they are transferred onto textiles. The quality of the transfer film directly influences the vibrancy and longevity of the final print. Various types of films exist, with differences in texture, thickness, and compatibility with different ink formulations. Selecting the right transfer film can make a significant difference in the overall quality of the printed products.

Moreover, advancements in DTF transfer film technology have led to films that provide better adhesion and easier handling. Many modern transfer films are designed to work seamlessly with eco-friendly DTF inks, ensuring that the final product is not only beautiful but also sustainable. As a DTF printing practitioner, understanding the specifications and benefits of different transfer films can help you optimize your workflow and product offerings.

Choosing Quality DTF Inks

DTF inks are specially formulated water-based inks that are essential for creating vibrant and durable prints. These inks are designed to adhere well to the transfer film and fabric, ensuring that colors come out bright and true. When selecting DTF inks, it’s important to consider their compatibility with your printer and transfer film, as not all inks deliver the same performance. Using high-quality inks will not only enhance the visual appeal of your prints but also ensure they stand the test of time.

Recent innovations in DTF inks have focused on improving their environmental impact. Manufacturers are now creating inks that are not only high performance but also less harmful to the environment. This aligns with the growing trend towards sustainability within the printing industry, appealing to eco-conscious consumers. By selecting inks that not only deliver quality results but also adhere to sustainable practices, DTF printing professionals can gain a competitive edge.

Heat Press Machines: A Critical Component

Heat press machines play a vital role in the DTF printing process, serving as the mechanism through which designs are permanently affixed to garments. Choosing the right heat press can significantly impact the outcome of your prints. Factors like temperature accuracy, pressure control, and size should all be considered when selecting a heat press. Investing in a high-quality heat press ensures that the prints adhere properly to the fabric, enhancing the overall durability and appearance of the final product.

Additionally, advancements in heat press technology have introduced machines with advanced features such as digital displays and automatic pressure adjustments. These innovations simplify the printing process and reduce the margin for error, making it easier for users to achieve consistent, professional results. As DTF printing grows, understanding how to effectively utilize heat press machines can empower both hobbyists and professionals to elevate their printing capabilities.

Latest Market Trends in DTF Supplies

The DTF printing market is experiencing rapid growth driven by the demand for customized and high-quality printed merchandise. As e-commerce surges, so does the need for personalized products, leading to a higher demand for DTF supplies. This market expansion is not only limited to apparel but extends to promotional materials, home decor, and fabric accessories. Staying informed about these trends allows businesses to tailor their offerings and effectively compete in the marketplace.

Another significant trend is the emphasis on sustainability. As consumers become more eco-conscious, manufacturers of DTF supplies are responding by offering eco-friendly inks, biodegradable transfer films, and recyclable packaging. This focus on sustainable practices not only meets consumer demands but also positions brands as responsible market players. By aligning with these trends, businesses can enhance their brand image while contributing to a healthier environment.

Educational Resources for DTF Enthusiasts

To maximize the potential of DTF printing, continuous learning through educational resources is essential. Many companies provide workshops, online tutorials, and webinars that cater to both novice and experienced users. These resources help individuals understand the nuances of operating DTF equipment effectively and offer tips on improving print quality. Engaging with educational content fosters a community of learners eager to refine their skills and stay updated on industry advancements.

Additionally, many platforms offer forums and online communities dedicated to DTF printing where users can share tips, troubleshoot issues, and discuss the latest trends. Connecting with other DTF enthusiasts can enhance one’s understanding of best practices while providing valuable insights into the market. Emphasizing learning not only benefits individual print quality but also contributes to the overall growth of the DTF printing community.

Frequently Asked Questions

What are essential DTF supplies for successful printing?

Essential DTF supplies include DTF printing equipment like specialized printers, DTF transfer film for transferring designs, DTF inks that are water-based and eco-friendly, heat press machines for applying the designs, and transfer powders that help adhere prints to fabric during the heat press process.

How does DTF printing equipment differ from traditional printing methods?

DTF printing equipment uses specialized printers designed explicitly for the DTF printing process, allowing for high-quality and flexible printing on various fabrics. Unlike traditional methods, DTF printing enables vibrant color reproduction and intricate design application on-demand.

What role does DTF transfer film play in the printing process?

DTF transfer film serves as the medium for printing designs before transferring them onto textiles. It must be compatible with DTF inks to ensure optimal adhesion and high-quality results during the heat press application.

What types of DTF inks are available and what are their benefits?

DTF inks are primarily water-based and designed to work well with DTF transfer films. They offer advantages such as vibrant colors, durability, and eco-friendliness, making them ideal for sustainable printing practices.

Why is the heat press machine critical to the DTF printing process?

The heat press machine is critical to the DTF printing process because it applies the necessary temperature and pressure to transfer the printed design from the DTF transfer film onto the fabric. The correct heat press ensures optimal adhesion and print longevity.

What recent advancements have been made in DTF supplies?

Recent advancements in DTF supplies include faster and more precise DTF printers, improved DTF inks for enhanced durability and vibrancy, and more efficient transfer powders that reduce the time needed for successful print transfers, contributing to faster production.

| Key Point | Details |

|---|---|

| What is DTF Printing? | DTF printing is a technology that prints designs onto a specialized film before transferring them onto textiles, allowing flexibility with various fabrics. |

| Essential Supplies for DTF | DTF Printers, Transfer Films, DTF Inks, Transfer Powders, Heat Presses are crucial for achieving high-quality prints. |

| Recent Advances in DTF Supplies | Modern DTF printers offer improved speed and precision, while newer inks and powders enhance durability and eco-friendliness. |

| Market Trends in DTF Supplies | Growing demand due to e-commerce, sustainable practices being prioritized, and flexibility in customization for businesses. |

| Key Vendors | BELQUET, DTF Superstore, and Apliiq are notable vendors offering a range of DTF printing solutions. |

| Educational Resources | Workshops and online tutorials help users effectively navigate the DTF printing process. |

Summary

Essential DTF Supplies are fundamental for achieving high-quality results in textile printing. As Direct-to-Film printing technology continues to advance, understanding the necessary supplies—such as specific printers, films, inks, and heat press equipment—will help both professionals and novices enhance their printing capabilities. With an increasing focus on sustainable practices and customization options, embracing these essentials will not only improve print quality but align with industry trends. As you explore your DTF printing journey, keeping abreast of the latest innovations and ensuring you have the appropriate resources will set you on the path to success.