California DTF Materials: Inks, Films & Substrates

California DTF materials have reshaped how apparel printers approach decoration, delivering vibrant designs with strong wash-fastness across a wide range of fabrics, while balancing performance, sustainability, and cost considerations. If you’re new to direct-to-film printing or seeking to optimize an existing workflow, understanding the key components—DTF inks, DTF films, and DTF substrates—is essential for consistent, compliant, and cost-efficient production. This guide will demystify California DTF materials, explain how each element works, and offer practical tips to boost color accuracy, consistency, production efficiency, waste reduction, and on-time delivery. By focusing on inks, films, and substrates, you’ll gain a clear picture of how to assemble a reliable DTF printing materials kit that performs reliably in real-world shop conditions, scales with demand, and adapts to evolving market needs. From sourcing to setup, the alternatives and tradeoffs you’ll encounter in California are manageable when you test, document, and standardize your process for sustainable growth.

From a regional perspective, the same mix of DTF inks, films, and substrates powers successful heat-transfer designs in California. This alternative framing highlights the network of components that make direct-to-film printing possible, including ink chemistry, film release behavior, and substrate compatibility. By evaluating ink palettes, film formulations, and fabric substrates together, shops can predict color fidelity, adhesion, and wash durability under local conditions. Direct-to-film printing workflows in this market benefit from close collaboration with suppliers who can provide test lots, compatibility data, and practical setup guidance. The goal is to establish a repeatable process that reduces reprints and keeps workflow efficient as you scale. With careful selection and documentation, you can create a resilient kit of printing materials that translates across designs and fabrics, while staying compliant with regional standards.

Choosing the Right DTF Inks for Vibrant, Durable Prints

DTF inks are the lifeblood of any direct-to-film printing setup. They must deliver rich color, strong white underbases, and robust wash-fastness while remaining compatible with the film and adhesive powder you rely on. Inks designed for pigment-based workflows often offer the best lightfastness and opacity, which is essential for accurate reproduction on dark garments. When evaluating DTF inks, look for formulations that balance color range with solid opacity to ensure vibrant results across a variety of fabrics.

Beyond color performance, compatibility is crucial. The inks must work harmoniously with your DTF film, adhesive system, and post-print curing process. Consider factors such as cure time, odor and safety, and VOC content, since these influence workplace safety and overall production efficiency. By prioritizing reliable inks, you reduce reprints, improve color matching, and create a stable foundation for your California DTF materials workflow.

DTF Films: Finding Consistent Release and Edge Definition

DTF films are the carrier that carries your ink from print to garment, so their release characteristics and edge fidelity directly impact transfer quality. Film thickness and clarity influence edge definition, texture, and how crisply an image transfers onto different fabrics. A well-chosen film should release ink cleanly under heat and pressure while maintaining dimensional stability during handling.

Backer compatibility and adhesive interaction also matter. Some films pair best with certain adhesive powders or backing coatings, and misalignment or tackiness can lead to imperfect transfers. In practice, California shops often run controlled test prints across representative fabrics to confirm that the film and ink combination delivers consistent density, sharp edges, and reliable performance after multiple washes.

DTF Substrates: Matching Fabrics for Best Performance

Substrates—the fabrics you print onto—are arguably the most variable factor in the DTF process. Cotton, cotton blends, and 100% polyester each respond differently to pretreatment, ink density, and heat exposure. Understanding substrate chemistry helps you tailor your workflow so colors stay true and adhesion remains durable after washing.

Pretreatment considerations, fabric texture, and color choice all influence the final result. Dark fabrics, for example, require a strong white underbase to reproduce accurate color, while textured surfaces may reveal edge irregularities if transfer pressure isn’t uniformly applied. California printers often test substrates with a consistent setup to ensure predictable outcomes across different job types and supply sources.

California DTF Materials: Compliance, Suppliers, and Local Considerations

California DTF materials must meet regional regulations, including VOC limits and safety data requirements. Local supplier proximity can shorten restock cycles and provide hands-on technical guidance for complex material kits. Paying attention to regulatory compliance helps protect your shop, employees, and customers while maintaining smooth production flows.

Regional considerations also include climate and supply chain realities. Temperature and humidity affect ink drying times, adhesive behavior, and film handling, so adjusting cure schedules and storage practices is prudent. Build relationships with reputable California suppliers who offer test lots and clear return policies, and maintain a library of tested ink/film/substrate combinations to reproduce successful results quickly.

Optimizing Color Management in Direct-to-Film Printing

Color management is critical for predictable results in direct-to-film printing. Prepare artwork with accurate color profiles and simulate color density on representative substrates to anticipate how prints will look after transfer. A robust workflow uses calibrated monitors, ICC profiles, and consistent print settings to minimize deviations between the design and the final garment.

In practice, achieving consistent color means controlling ink density, white underbase strength, and film-to-substrate transfer dynamics. Regular calibration prints, cross-checks with known fabrics, and careful documentation of settings help you reproduce the same vibrant results across jobs. When you align DTF inks, DTF films, and substrates with disciplined color management, the overall quality and customer satisfaction rise.

Workflow, Testing, and Quality Assurance for Consistent DTF Results

A repeatable DTF workflow starts with design and color management, then moves through printing, powder application, curing, transfer, and finishing. Each step relies on the predictable behavior of inks, films, and substrates to deliver consistent results. Documenting your standard operating procedures (SOPs) for common fabric types helps your team maintain uniform quality, batch after batch.

Quality assurance hinges on systematic testing, including calibration prints, test swatches, and performance checks after multiple washes. Avoid mixing inks or films from incompatible lines, and store films and powders in controlled environments to preserve performance. By building a disciplined process around DTF printing materials and cycles, you’ll reduce waste, shorten setup times, and increase reliability across a growing catalog of orders.

Frequently Asked Questions

What are California DTF materials and why are inks, films, and substrates essential for direct-to-film printing?

California DTF materials refer to the three core components used in direct-to-film printing: DTF inks, DTF films, and DTF substrates. Inks provide color and white underbase, films carry the ink and determine release during transfer, and substrates are the fabrics the design is printed on that affect adhesion and durability. For consistent results in California shops, select inks compatible with your film and substrate, use films with stable release properties, and choose substrates with proven adhesion.

How do DTF inks impact color vibrancy and wash-fastness in California DTF materials for direct-to-film printing?

DTF inks—typically pigment-based with a white underbase—determine color gamut, brightness, and durability. Key factors are color range, opacity, compatibility with the film and adhesive, and wash-fastness. In California, consider water-based, low-VOC inks when possible to improve safety and odor without sacrificing performance. Proper curing and pairing with the film/adhesive system helps prevent bleeding and fading.

What should I look for in DTF films when using California DTF materials for consistent direct-to-film transfers?

Choose DTF films with stable release properties and predictable ink lift, and an appropriate thickness for your ink set. Look for compatibility with your white and color inks and adhesive powder, as well as heat resistance to avoid warping. Test prints on representative fabrics to confirm color density, edge definition, and transfer durability.

Which substrates work best with California DTF materials for durable prints on different fabrics?

Substrates vary by fabric type—100% cotton, cotton-poly blends, and 100% polyester each require different ink densities and pretreatment needs. Pretreatment and surface energy control adhesion and vibrancy; test on common garments to optimize results. Substrate selection in California should consider availability, wash durability, and any fabric certifications relevant to your shop.

How can I optimize a direct-to-film printing workflow in California using reliable DTF printing materials?

Start with a matched trio: DTF inks, DTF films, and DTF substrates that work well together. Implement consistent color management, run test prints on representative fabrics, and document settings for repeatability. Consider regional factors like supplier proximity, local regulations, and climate that affect curing times and film handling.

What testing and calibration steps help ensure reliable results with California DTF materials?

Perform calibration prints on representative fabrics to verify color density and transfer coverage. Regularly test wash durability and edge definition after multiple cycles. Maintain a log of ink–film–substrate combinations and revalidate when batches or suppliers change. This disciplined approach aligns with California DTF materials best practices.

| Focus Area | Summary | Key Points |

|---|---|---|

| Inks (DTF inks) | DTF inks are pigment-based and form the color foundation by adhering to the film’s white adhesive layer, then transferring to fabric. They should dry quickly enough to handle the film and cure properly to resist smearing and washing. | – Wide color range and white opacity for bright prints on dark fabrics – Must be compatible with film and adhesive powder – Good wet-on-wet performance and adequate cure time – Strong wash-fastness and durability – Low odor/VOC options for safer workplaces – Reliable supplier quality and availability for consistent color results – Balance ink quality with film/substrate choices for best results – Consider maintenance of a stable ink supply to reduce reprints and color matching issues. |

| Films (DTF films) | Films carry ink from print to garment and must release cleanly under heat/pressure. Their thickness, clarity, and release behavior influence color accuracy and edge definition. | – Film thickness/clarity affect edge sharpness and calibration needs – Release characteristics crucial to preventing ghosting or incomplete transfers – Backer compatibility with adhesive powders and coatings – Durability and heat resistance to withstand multiple transfers – Test prints on representative fabrics to verify color density, edge definition, and wash durability – Choose films with consistent release and ink compatibility with your ink set |

| Substrates | Fabrics you print on vary in behavior; pretreatment, ink density, and heat exposure all influence adhesion and image quality. | – Fabric composition (cotton, blends, polyester) dictates ink density and pre-treatment needs – Pretreatment requirements to improve adhesion and color vibrancy – Color/texture impact on transfer appearance and edge quality – Wash durability and substrate compatibility with the ink system – Availability, certifications, and local supply considerations – Test across common garment types to standardize workflows |

| DTF Process (Design to Garment) | A typical workflow from artwork to finished transfer, highlighting the interaction of inks, films, and substrates. | – Design and color management with proper color profiles – Print on film with appropriate ink density – Apply adhesive powder while film is warm and cure/dry per guidelines – Cure the powder to create a transferable layer – Transfer to fabric with correct heat, time, and pressure – Peel and inspect for coverage and alignment – Regular calibration and testing to maintain consistency across runs |

| California-Specific Considerations | Regional factors can affect material choice and workflow in California, including local suppliers, regulatory constraints, and climate differences. | – Proximity to suppliers and lead times; on-site technical guidance – VOC content, safety data sheets, and regulatory compliance considerations – Temperature/humidity variance between coastal and inland areas and its effect on drying times and adhesive behavior – Build relationships with reputable suppliers; maintain test lots and a documented material library |

| Practical Tips and Common Pitfalls | Practical guidance to maintain consistency and reduce errors. | – Do not mix inks or films from incompatible lines – Store films and powders in controlled conditions to prevent moisture uptake or tackiness – Run calibration prints regularly, especially when changing batches or suppliers – Document settings for common fabrics and designs as SOPs – Use PPE and follow safety guidelines when handling powders and inks |

| Choosing the Right California DTF Materials for Your Shop | A practical approach to selecting a reliable, compatible material trio for California operations. | – Start with a simple, well-matched trio: inks with strong white underbase, a film with stable release, and substrates with predictable adhesion – Systematically test ink/film/substrate combinations to find best fits for common jobs – Invest in predictable ink density control, durable film performance, and substrates with consistent fiber content and surface energy – Build supplier relationships that offer test lots and technical support |

| Conclusion (Summary of Core Points) | A concise takeaway of the main ideas for DTF materials and their role in successful production. | – Inks, films, and substrates collectively determine color vibrancy, transfer reliability, and durability – Consistent material matching and testing reduce reprints and improve shop efficiency – California-specific considerations include supply, regulation, and climate factors – A disciplined workflow and documented standards yield predictable, professional results over time |

Summary

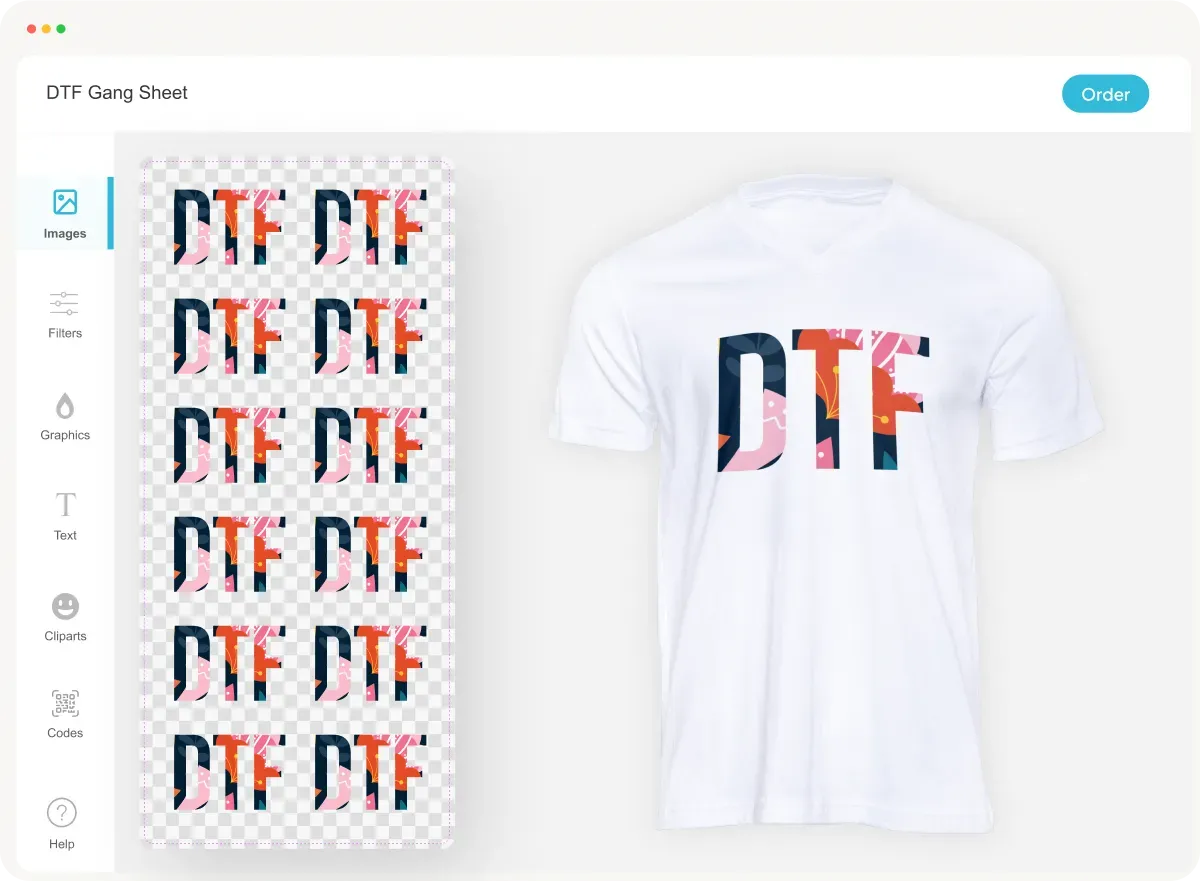

California DTF materials table summarizes the core points across inks, films, substrates, process, regional considerations, tips, and material selection. The table emphasizes consistent testing and documentation to achieve reliable, vibrant transfers for California shops.