DTF gangsheet builder: Fast, flawless print runs for you

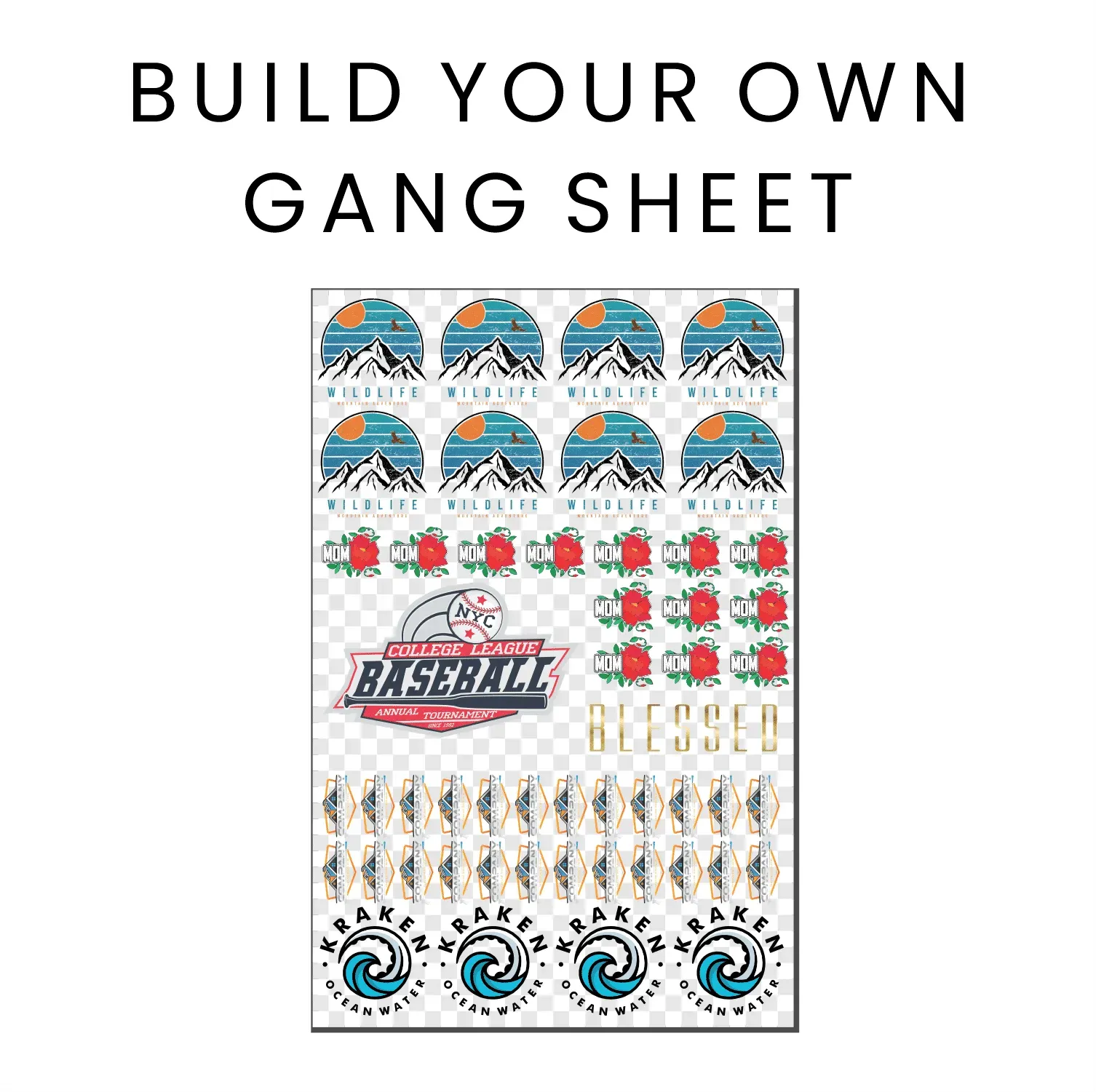

DTF gangsheet builder is a game changer for scaling garment decoration while preserving quality. When you print multiple designs on a single sheet, you boost gangsheet optimization, cut setup time, and reduce material waste. This DTF printing guide demonstrates how to leverage a DTF gangsheet to coordinate color, layout, and DTF printer setup for fast print runs. You’ll learn practical steps to align placements, manage color separations, and build repeatable workflows that scale your operations. Whether you’re new to DTF or refining an existing line, these practices help you deliver consistent results with higher throughput.

Put simply, a gangsheet layout tool acts as a transfer-sheet optimizer, placing several designs on one sheet to maximize material use. This concept relies on color management, precise positioning, and pre-press validation to deliver consistent results in high-volume runs. By thinking in terms of multi-design batching, sheet mosaics, and color-aware sequencing, you create a scalable workflow that aligns with production goals.

DTF gangsheet builder: master gangsheet optimization for fast print runs

DTF gangsheet builder is a game changer for scaling up garment decoration. By arranging multiple designs on one DTF sheet, it drives gangsheet optimization and reduces setup time, material waste, and overall print startup time. This approach supports fast print runs by maximizing the number of designs per sheet without sacrificing color fidelity or registration, aligning with a practical DTF printing guide that emphasizes efficient layout, color planning, and pre-press verification.

To use it effectively, start with clear design prep and a standard sheet size that fits your printer, plus consistent margins. Leverage ICC color profiles for color management and plan color separations to minimize color changes during printing. The DTF printer setup step—covering bed leveling, ink density calibration, and running soft proofs—ensures placement and scale are correct before committing to a batch, delivering faster throughput and more predictable results per run.

DTF printing guide: scalable production with optimized DTF printer setup and sheet layout

DTF printing guide: scalable production hinges on mastering sheet layout, color management, and printer setup. This guidance emphasizes organizing multiple designs per sheet to maximize throughput while maintaining color accuracy, utilizing transfer film compatibility, and ensuring alignment across designs. By focusing on standardized sheet sizes and margins, it supports fast print runs and repeatable results across orders.

Practical steps include templates for common sheet sizes, batch processing planning, robust color separation workflows, and version control for design variants. Address potential issues with soft proofs and test prints, calibrate ink density, and verify substrate compatibility with the transfer film. Following these best practices helps teams achieve consistent quality and scalable output in line with a comprehensive DTF printing guide.

Frequently Asked Questions

What is a DTF gangsheet builder and how does it support fast print runs?

A DTF gangsheet builder is software or a workflow that arranges multiple designs on a single transfer sheet, optimizing layout, color management, and registration to maximize designs per sheet. This approach reduces setup time, material waste, and press stops, enabling fast print runs with consistent results. To use it effectively, plan a standard sheet size and margins, align color profiles (ICC) to the substrate, organize designs by color and area, and perform a pre-press verification before printing.

What steps in a DTF printing guide should I follow to design an efficient gangsheet with a DTF gangsheet builder for fast print runs?

Follow a practical workflow: gather all designs, choose a standard sheet size and margins, place designs in an efficient grid, and run a soft proof to verify scale and alignment. Prepare color separations and set up your DTF printer (DTF printer setup) for the batch, using templates to speed assembly and gangsheet optimization to minimize ink changes. Finally, run QC checks during production to catch issues early and maintain consistent, high-quality output.

| Aspect | Key Points |

|---|---|

| What is a DTF gangsheet builder? |

|

| Benefits for fast, flawless print runs |

|

| Key design considerations |

|

| Step-by-step: building a DTF gangsheet |

|

| Best practices for speed and reliability |

|

| Troubleshooting common issues |

|

| Advanced tips and workflows |

|

Summary

Table summarizes the key points about the DTF gangsheet builder and its use.