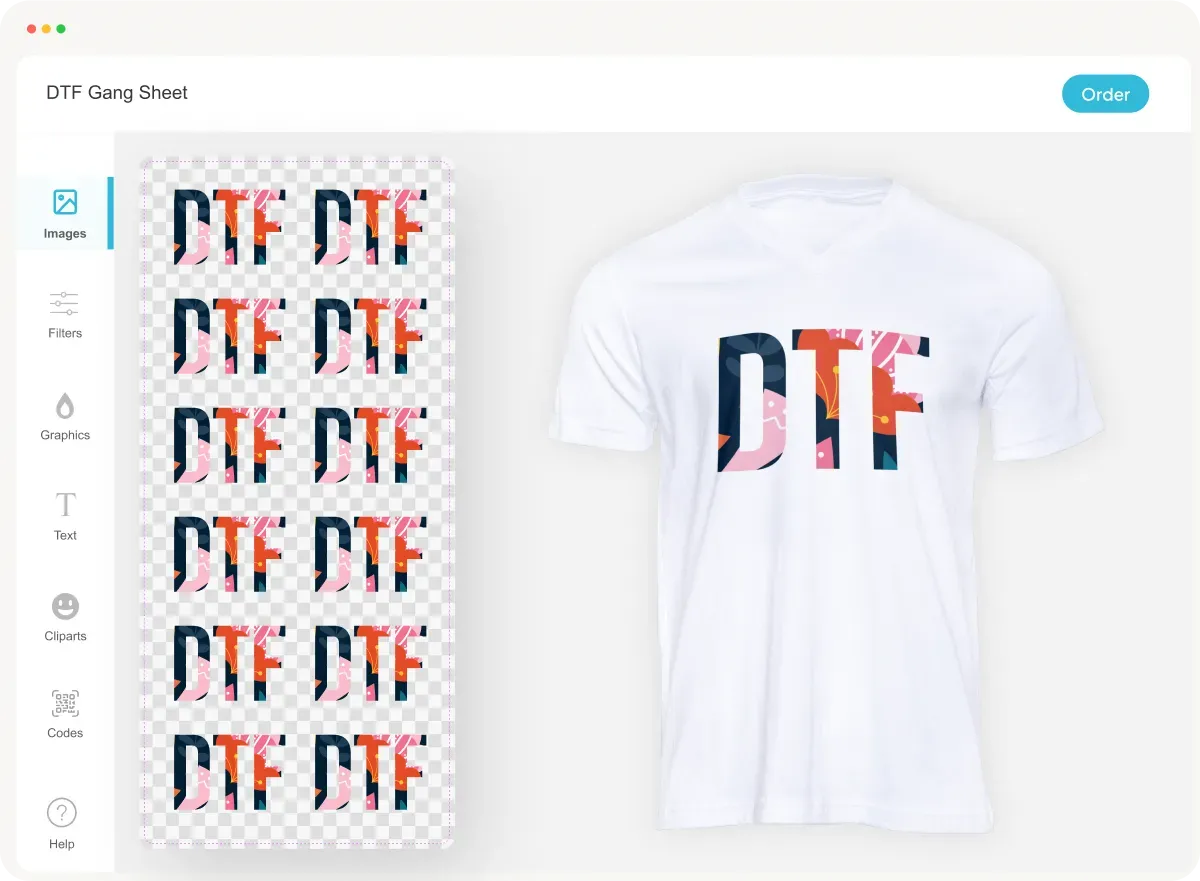

The DTF gangsheet builder is a pivotal tool for coordinating multiple designs on a single print sheet, helping teams plan large runs with precision. By orchestrating layouts across thousands of units, it supports large-scale DTF production strategies while reducing waste and setup time. It also powers DTF gang sheet optimization, enabling tighter packing, consistent separations, and efficient asset management. As part of the DTF printing workflow, it integrates with gangsheet design tools to validate margins, color targets, and alignment before sending jobs to RIPs. With standardized DTF color management for large runs, the builder ensures predictable outcomes across fabrics, boosting throughput while maintaining quality.

Viewed through an alternative lens, this technology acts as a transfer-sheet planner, a layout engine, and a production-efficient design studio that maps designs to garment sizes and colorways. LSI-friendly terms such as gangsheet designer, print sheet optimizer, and asset-driven planning capture the same idea from different angles. In practice, these tools coordinate asset libraries, enforce margins, and anticipate color consistency across runs, enabling smoother prepress and faster approvals. By framing the function as a sheet-placement and color-accurate workflow, teams can articulate benefits in terms familiar to designers, printers, and operations. Ultimately, these alternatives describe the same core capability: a scalable system that aligns artwork, sizes, and colors to deliver reliable large-scale outputs.

Frequently Asked Questions

How can a DTF gangsheet builder enhance large-scale production strategies and improve throughput?

A DTF gangsheet builder enables DTF gang sheet optimization by laying out multiple designs on a single sheet while respecting margins and bleed. This reduces material waste, speeds up pre-press, and increases throughput across thousands of garments, supporting large-scale production strategies. It also promotes a consistent DTF printing workflow with reliable results across runs.

What should you consider for effective DTF color management for large runs when using a gangsheet builder?

For DTF color management for large runs, standardize color profiles (CMYK equivalents for DTF inks) and convert assets to the target color space before gangsheet placement. Use the gangsheet design tools to preview color accuracy on typical fabrics, maintain a color reference library, and integrate with the DTF printing workflow and RIP to ensure consistent color across batches and minimize reprints.

| Aspect |

Key Points |

| What is a DTF gangsheet builder? |

- Software that plans and layouts multiple transfer designs on a single sheet for direct-to-film printing.

- Aims to maximize designs per sheet while respecting margins, bleed, and alignment tolerances.

- Key benefits: reduced material waste, faster setup, improved throughput, and consistent color output across large runs.

|

| Why it matters for large-scale productions? |

- Enables efficient gangsheet planning to handle thousands of garments.

- Improves throughput, reduces material waste, and ensures color consistency across items.

- Supports scalable workflows and integration with broader DTF printing pipelines.

|

| Strategies for large-scale productions |

- Start with a clear asset and order plan: build a master asset library organized by design, colorway, and size; map out production calendar and order queue; establish constraints such as margins, heat settings, and ink limits.

- Maximize sheet usage with gang sheet optimization: arrange multiple designs on one sheet with tight packing; consider overlapping only if it won’t affect separations or color accuracy; use auto-layout features to compare layouts.

- Color management for large runs: implement standardized color profiles; convert assets to the target color space; preview colors under typical lighting; maintain a color reference library.

- Streamlined printing workflow and automation: connect the gangsheet builder with RIP/printer queue; automate pre-press checks for resolution, hard edges, and line weights; balance machine load.

- Quality assurance and proofing: establish robust proofing; use calibration tools and test swatches; create a feedback loop from production to design.

- Continuous improvement and scalability: regularly review layouts, track metrics (sheets/hour, waste, color deviation), and plan for scalable asset libraries and schedules.

|

| Tools and techniques that power gang sheets |

- DTF gangsheet builder: core tool to lay out designs, respect margins, bleeding, and alignment; integrates with other workflow components.

- Gangsheet design tools: dragging, snapping, auto-arranging, validation.

- Color management and profiles: standardized color workflows for consistency.

- Print queue and RIP integration: seamless handoffs to RIPs and printers to minimize setup time.

- Asset management: centralized library for designs, colorways, sizes, and branding elements.

- Quality assurance modules: pre-press checks, validation rules, tolerance thresholds.

|

| Practical workflow: from design to production |

- Asset intake and preparation: gather art files, confirm brand guidelines, define color targets; prepare designs at appropriate resolutions; tag designs with metadata.

- Gangsheet creation and optimization: place designs on a sheet, respect margins/bleed; run optimization scenarios; preview layouts.

- Pre-press checks and export: automated checks for resolution and color readiness; export gang sheets to RIP with correct profiles.

- Production and monitoring: load sheets into printer queue; monitor throughput, waste, color consistency; capture operator feedback.

- Post-production analysis: review run metrics; update asset libraries and templates.

|

| Case study: planning a large run |

- Scenario: 12 designs, 5 colorways, 5 sizes; goal 2,000 units across three shipments in two weeks.

- Approach: create a master gangsheet template, optimize layouts to maximize density, standardize color targets, perform pre-press validation.

- Execution: run production with QA checks, monitor alignment and color repeatability.

- Optimization: review metrics post-run and refine templates and asset organization for future runs.

|

| Pitfalls to avoid when building gang sheets for large runs |

- Overpacking layouts can cause misalignment or color bleed; respect margins and bleed.

- Inconsistent asset preparation leads to color variation; enforce color workflows.

- Lack of version control can cause confusion; maintain version history.

- Underestimating color management leads to reprints; validate with test prints.

- Rigid processes slow scaling; build flexible templates and scalable asset libraries.

|

| Future trends and takeaways |

- AI-assisted layout optimization and smarter gangsheet design.

- Tighter integration between asset management and gangsheet tooling.

- More robust color management pipelines across fabrics and machines.

- Rapid generation of optimized gang sheets to support complex, large-scale runs.

|

Summary

DTF gangsheet builder is a strategic asset for teams scaling direct-to-film production. By focusing on gangsheet optimization, standardized color management, and streamlined workflows, you can dramatically improve throughput, reduce waste, and deliver consistent results across thousands of garments. Embracing these strategies and the right tools will position your operation to meet growing demand with efficiency and quality.