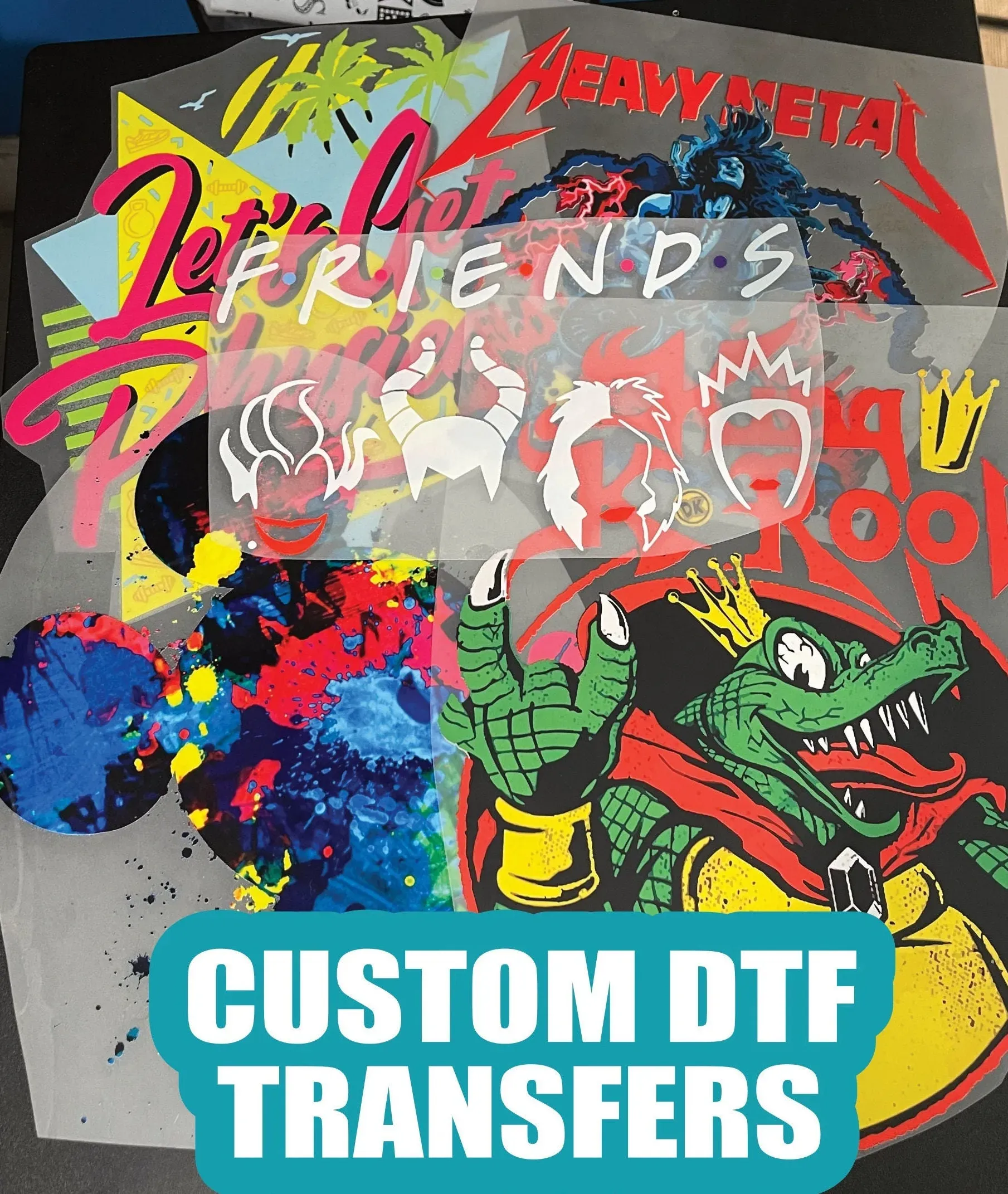

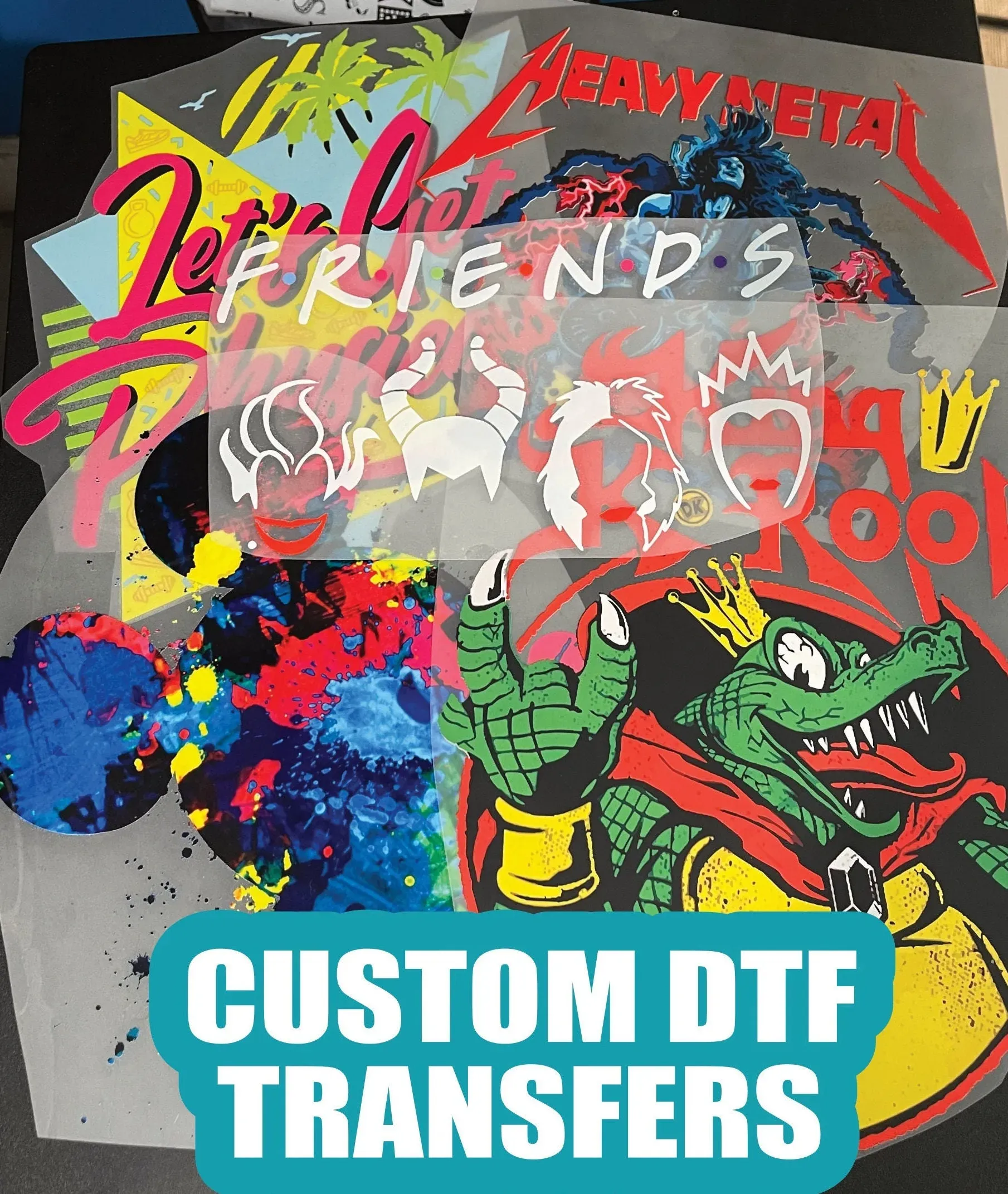

DTF Supplies: Boost Your Printing Business Today

DTF Supplies are revolutionizing the way businesses approach custom garment printing, providing an innovative solution that enhances both efficiency and print quality. The rise of DTF (Direct to Film) printing technology has empowered printing businesses with the ability to produce vibrant, durable designs on a variety of fabrics, making it a game-changer in the industry. With essential DTF transfer films, high-quality DTF printers, and specialized inks, entrepreneurs can cater to the growing demand for personalized apparel while optimizing their workflow. This blog post will delve into the critical DTF supplies that every printing business should consider to stay competitive and thrive in today’s market. By harnessing the power of DTF supplies, you can elevate your printing services and stand out in a bustling industry.

When discussing Direct to Film options, it’s important to recognize how this modern printing method transforms the creation of custom prints. Known for its versatility, DTF technology allows businesses to print intricate designs on various materials with ease. This approach not only streamlines the printing process but also appeals to customers seeking uniqueness in their apparel. By exploring available DTF transfer films, printers, and inks, you can equip your business with the tools needed for success in the ever-evolving world of printing. Embracing this innovative technology will not only enhance print quality but also position your business favorably among competitors.

Maximizing Quality with DTF Printers

A crucial component for any printing business looking to embrace DTF technology is the selection of printers. DTF printers are specialized for producing high-resolution images that can be effectively transferred onto various fabrics. Brands like Epson and Roland are at the forefront of this technology, providing reliable options that ensure both efficiency and quality. When choosing a DTF printer, consider factors like print speed, ink efficiency, and the types of designs you wish to produce. Selecting the right printer sets the foundation for your successful DTF printing operation.

Moreover, investing in a reliable DTF printer directly impacts your ability to fulfill customer orders. Fast and reliable output not only keeps your workflow smooth but also enhances customer satisfaction. Printers that offer better integration with your design software and provide consistent color reproduction can greatly reduce production time and errors. Ultimately, your choice of printer can significantly affect both the quality of your prints and your overall production capacity.

Understanding DTF Inks for Vibrant Results

The quality of DTF inks is another critical aspect that influences the final outcome of your prints. Specialized DTF inks are designed to provide vibrant colors and excellent adhesion to fabrics, ensuring that your designs remain bright and intact even after multiple washes. Reputable brands like A&N and Polyprint provide inks that are formulated to help achieve this desired outcome, making them popular choices among printing professionals.

In addition to color vibrancy, the environmental impact of inks is becoming increasingly important in the printing industry. Water-based DTF inks are favored not only for their outstanding print quality but also for their lower environmental footprint. As a printing business, choosing inks that are less harmful to the environment can enhance your brand image and appeal to eco-conscious consumers, aligning your business with current market trends.

The Role of Transfer Films in DTF Printing

Transfer films are instrumental in the DTF printing process, directly influencing the final look and feel of printed garments. Selecting high-quality DTF transfer films that are compatible with your printer is essential for optimal adhesion and print clarity. Various types of films vary in texture and durability, so it’s crucial to consider the fabric types you will be printing on when choosing your films.

A reliable transfer film ensures that your prints not only look great but also withstand the test of time. Fabrics subjected to wear and washing will require a film that offers excellent durability, while soft-hand films provide a more comfortable feel for apparel. Investing in the right transfer films can ultimately lead to higher customer satisfaction and lower return rates due to print failures.

Exploring the Importance of Adhesive Powders

Adhesive powders play a vital role in ensuring that the printed designs adhere effectively to fabrics during the transfer process. This powder is melted onto the printed design before pressing it onto the garment, creating a strong bond that holds up well against washing and wearing. Quality adhesive powders are designed to offer excellent adhesion while remaining lightweight, ensuring that they do not interfere with the softness of the fabric.

Using the right adhesive powder can significantly enhance the durability of your prints. A good quality adhesive can provide a lasting bond, even on challenging fabrics, reducing the likelihood of peeling or cracking. Therefore, it is important for printing companies to source high-quality adhesive powders that complement their choice of inks and transfer films as part of a cohesive DTF printing process.

Investing in Efficient Heat Presses

The heat press is a pivotal tool in any DTF printing operation, as it ensures that the design is equally and effectively transferred onto the garment. A digital heat press that allows for precise control over temperature and pressure is essential for achieving optimal results. Inconsistent heat application can lead to poor adhesion or distorted images, which will negatively impact print quality.

When selecting a heat press, consider models that are known for their durability and ease of use. Features like an automatic timer, adjustable pressure settings, and even heating across the platen contribute to a smoother production experience. Investing in a high-quality heat press not only enhances print quality but also optimizes workflow, allowing you to handle a larger volume of orders effectively.

Staying Ahead with Market Trends in DTF Printing

The world of DTF printing is continuously evolving, with market trends shaping how businesses operate and meet consumer demands. Keeping an eye on innovations, such as broader color gamuts and improved materials, is crucial for any printing business that aims to stay competitive. The shift towards custom apparel and various fabric types means that businesses must adapt their offerings to cater to changing consumer preferences.

By staying informed about market trends, such as the increasing popularity of eco-friendly printing solutions and advancements in DTF technologies, businesses can position themselves as industry leaders. Attending trade shows, participating in workshops, and engaging with other printing professionals can provide insights into emerging trends, helping you make informed decisions that will grow your business and enhance customer satisfaction.

Frequently Asked Questions

What are the essential DTF supplies for starting a DTF printing business?

To start a successful DTF printing business, you need several essential supplies: a quality DTF printer (such as those from Epson or Roland), specialized DTF inks, high-quality transfer films, adhesive powder for bonding prints, and a reliable heat press for applying designs. Each of these supplies plays a critical role in ensuring the quality and durability of your prints.

How does DTF printing differ from traditional printing methods?

DTF printing, or Direct to Film printing, differs from traditional methods by allowing for vibrant, intricate designs to be transferred directly from a film onto various fabrics. Unlike screen printing, DTF is more cost-effective, especially for short runs, and requires less setup, making it ideal for custom garment printing in a dynamic market.

What types of fabrics can be used with DTF transfer films?

DTF transfer films are versatile and can be used on a variety of fabrics including cotton, polyester, and fabric blends. This flexibility makes DTF printing a popular choice for printing businesses, as it enables them to cater to a wide range of garment needs.

Are there any specific brands of DTF inks recommended for high-quality printing?

Yes, for high-quality DTF printing, brands like A&N and Polyprint are commonly recommended. They offer water-based inks that are specifically formulated for DTF applications, providing excellent adhesion and vibrant color output, essential for professional-grade prints.

What is the role of adhesive powder in the DTF printing process?

Adhesive powder is a key component in DTF printing as it bonds the printed design to the fabric. After printing your design on a transfer film, the adhesive powder is applied and melted during the heat transfer process, ensuring that the print adheres firmly to the fabric and remains durable through washes.

How can I ensure optimal results with my DTF heat press?

To ensure optimal results with your DTF heat press, invest in a digital model that allows precise control over temperature and pressure. Consistency is crucial; following the manufacturer’s guidelines and conducting test runs on different fabrics will help achieve the best transfer quality and durability.

| Key Point | Details |

|---|---|

| DTF Technology | A printing method that prints designs on a special film before transferring them to garments using heat. |

| Advantages | Includes versatility, cost-effectiveness, and ability to meet market demand for custom prints. |

| Essential Supplies | Printers, inks, transfer films, adhesive powder, and heat press are critical for successful DTF printing. |

| Market Trends | Growth driven by innovations like broader color gamuts and improved adhesive powders. |

| Training Opportunities | Online platforms and workshops help businesses learn DTF printing processes effectively. |

Summary

DTF Supplies can significantly enhance your printing business by providing high-quality printing capabilities essential for success in today’s market. With the innovative DTF printing technology, businesses can achieve superior print quality, versatility, and cost-effectiveness. Investing in top-notch DTF supplies, such as reliable printers, vibrant inks, and durable transfer films, ensures a professional output that can satisfy increasing customer demands for customized products. Furthermore, staying informed about market trends and continuously improving your skills in DTF printing will help your business thrive. By embracing DTF Supplies, you position your printing business to exceed consumer expectations and capitalize on emerging opportunities in the vibrant printing industry.