DTF Transfers: Transforming DIY and Small Business Printing

DTF transfers, or Direct-to-Film transfers, have revolutionized the way DIY enthusiasts and small businesses approach custom printed apparel. This groundbreaking printing method enables users to produce high-quality designs on various fabrics, such as cotton and polyester, with remarkable ease. With the growing demand for unique products, DTF transfers provide an innovative solution that empowers creators to make their visions a reality. Whether you’re launching a small business or pursuing a crafty passion, these versatile transfers offer an affordable and efficient means of creating stunning merchandise. In a competitive market where personalization is key, embracing DTF transfers can significantly enhance your printing capabilities and product offerings.

Also known as Direct to Film printing, DTF transfers have emerged as a game-changing technology in the realm of custom clothing production. This innovative method not only simplifies the creation of DIY transfers but also positions small business printing on the cutting edge of market trends. With heat transfer technology at its core, this technique allows artisans and entrepreneurs to easily replicate intricate designs on multiple materials. By leveraging these advanced printing strategies, users can produce custom printed apparel that stands out in a crowded marketplace. As the demand for personalized merchandise continues to grow, adopting DTF transfers can be a pivotal step toward achieving greater success and creativity.

Introduction to DTF Transfers: Revolutionizing Custom Printing

Direct-to-Film (DTF) transfers are redefining the landscape of custom printing, particularly for DIY enthusiasts and small businesses. This innovative technology allows users to create stunning designs that can easily be transferred onto an array of fabrics and surfaces. With its ability to deliver high-quality prints at a fraction of the cost of traditional methods, DTF transfers are quickly becoming a preferred choice for crafters looking to enhance their projects and offerings.

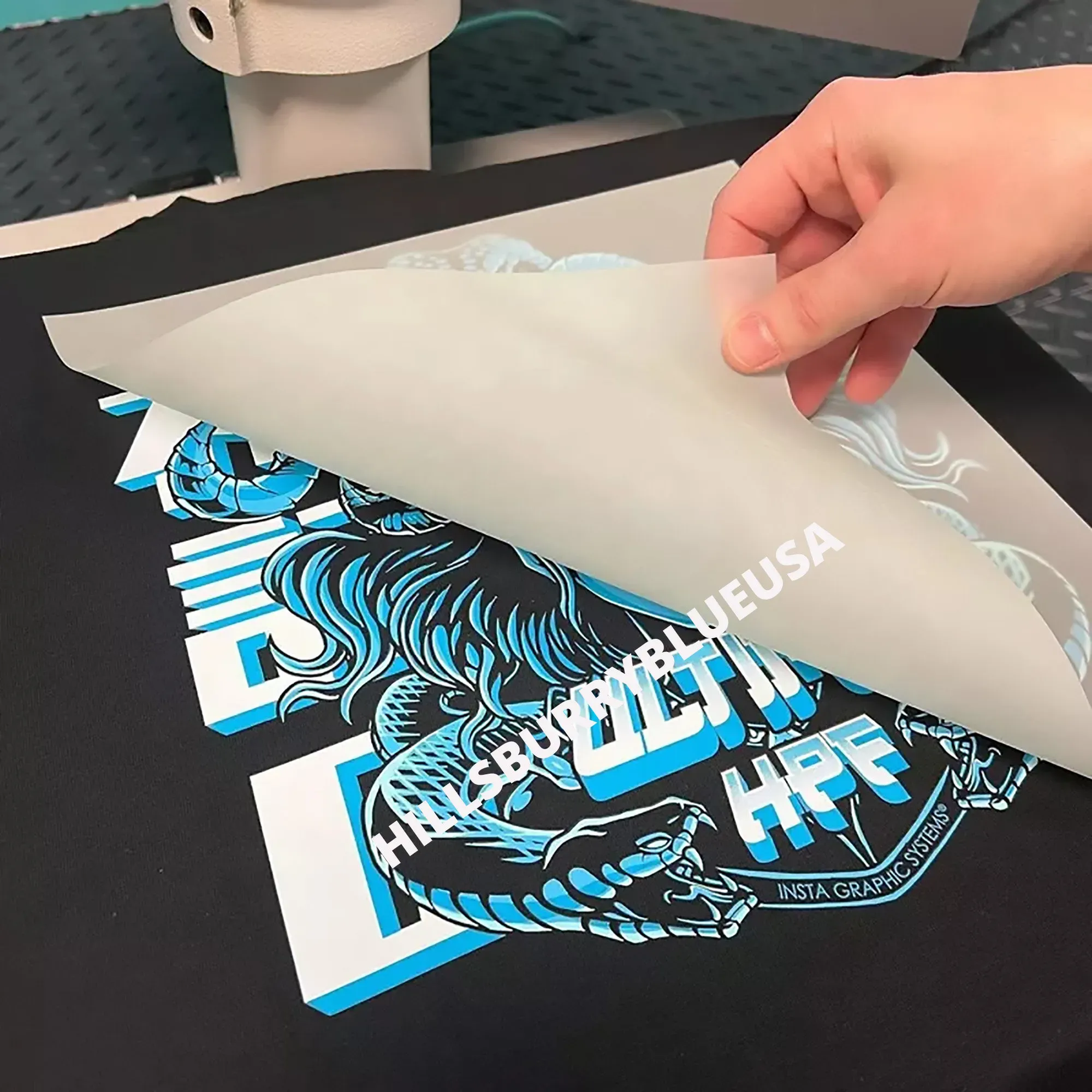

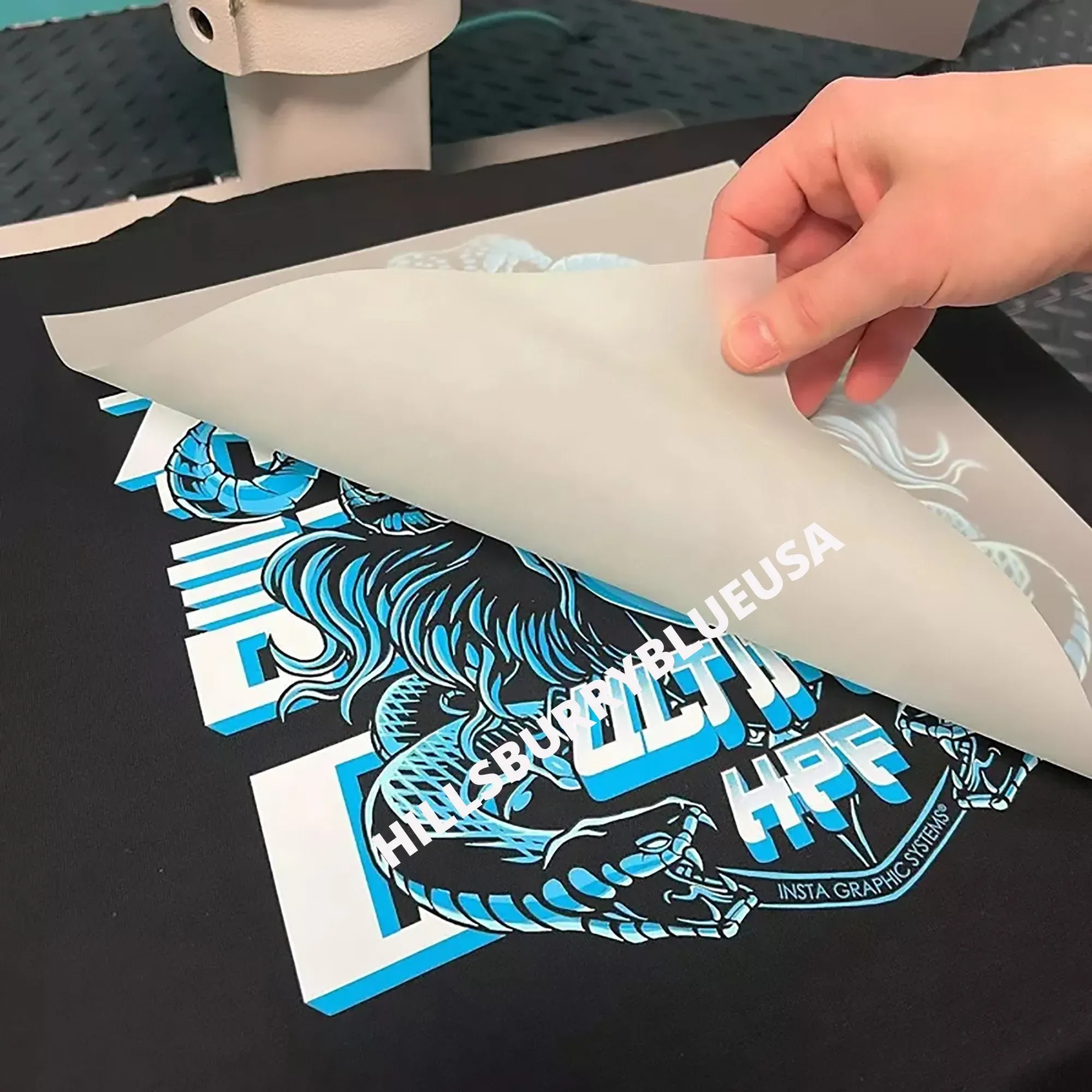

At the core of DTF transfer technology is the ability to print detailed and vibrant designs directly onto a durable film. Once printed, these designs can then be heat pressed onto various materials, making it an accessible solution for anyone wanting to enter the world of custom printed apparel. As e-commerce continues to expand, mastering DTF transfer techniques offers a unique selling point for small businesses seeking to stand out in an increasingly competitive market.

Affordable Printing Solutions for Small Businesses

One of the critical advantages of DTF transfer technology is its affordability, which has significantly decreased over recent years. Many small business owners have been able to invest in DTF printers that were previously too costly. This reduction in price not only makes it easier to enter the custom printing market but also empowers small entrepreneurs to compete with larger printing companies on quality and price.

The decrease in costs associated with DTF transfers paves the way for small business owners to diversify their product offerings without the financial strain. With the ability to create everything from custom t-shirts to intricate apparel designs, small businesses can maintain their uniqueness and cater to a growing audience eager for personalized products.

Simplicity and Efficiency of DTF Transfer Technology

The streamlined process of creating DTF transfers is a major selling point for both DIY enthusiasts and small business owners. Users can design graphics through digital software, print them onto the special DTF film, and apply them onto fabrics using a heat press with minimal effort. This straightforward workflow allows individuals to save time while producing high-quality outputs.

As time is often a limiting factor for small businesses, the efficiency of DTF printing means that owners can scale their operations quickly, meeting the demands of their customers without the hassle of complicated procedures. This ease of use fosters a creative environment where DIY projects and business production run smoothly, encouraging innovation in custom apparel.

Versatility of DTF Transfers Across Materials

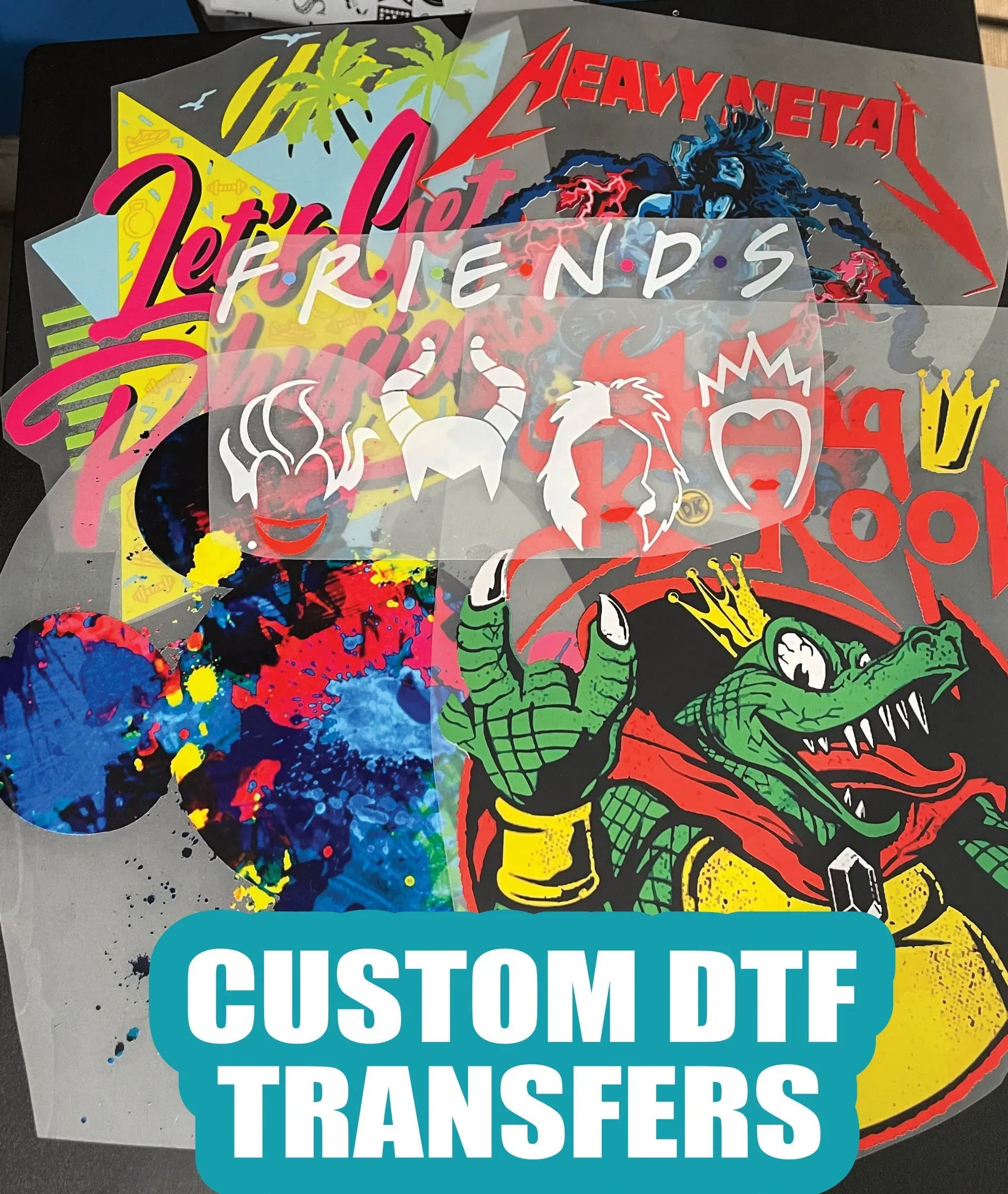

DTF transfers shine in their versatility, enabling users to print on various materials such as cotton, polyester, and blends. This capability makes them an excellent choice for producing a diverse array of products, including t-shirts, hoodies, caps, and tote bags. Such flexibility is essential for small businesses aiming to cater to various customer needs and preferences.

This adaptability not only helps businesses expand their product lines but also allows DIY creators to express their creativity across different fabric types. By embracing DTF printing, users can experiment with a multitude of designs and materials, enhancing both personal projects and business offerings with professional-quality results.

Ensuring Quality and Durability of DTF Prints

When it comes to print quality, DTF transfers often outperform traditional techniques such as screen printing or heat transfer vinyl. The vibrant colors and durability of DTF prints mean that designs remain intact and vivid, even through multiple washes. This quality assurance is pivotal for both DIY enthusiasts wanting to make lasting creations and small businesses aiming for customer satisfaction.

For small businesses, the reputation for delivering high-quality products can lead to repeat sales and referrals, making durability a crucial aspect of success. By investing in DTF transfers, business owners can guarantee that their custom printed apparel meets the growing consumer demand for long-lasting and visually appealing products.

Community Engagement and Educational Resources in DTF Printing

The rise of DTF transfers has cultivated a vibrant community passionate about DIY projects and small-business ventures. Users frequently share their experiences, tips, and best practices on social media and forums, creating an invaluable network of support for both new and seasoned printers. Engaging with this community offers insights that can enhance the overall user experience with DTF printing technologies.

Moreover, many members of the DTF community provide tutorials and guides that simplify the learning process, making it easier for beginners to dive into the world of custom printing. This wealth of shared knowledge not only fosters a more informed user base but also democratizes access to high-quality printing techniques, empowering a broader audience to leverage DTF technology for their creative and entrepreneurial endeavors.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, are a method of printing designs onto a special film that can be heat-pressed onto fabric. This process allows for vibrant, high-quality prints that are durable and suitable for a variety of materials, making it ideal for DIY transfers and custom printed apparel.

Why should small businesses consider using DTF transfer technology?

Small businesses should consider DTF transfer technology due to its affordability, ease of use, and versatility. With reduced costs for DTF printers, entrepreneurs can create custom printed apparel quickly, offering a wide range of products to meet consumer demand.

What types of materials can I use for DTF transfers?

DTF transfers can be applied to various materials, including cotton, polyester, and blends. This versatility allows for the production of a diverse array of items, from t-shirts to tote bags, making it an excellent choice for small business printing.

How do DTF transfers compare to traditional printing methods?

DTF transfers generally offer superior quality and durability compared to traditional methods like screen printing and vinyl heat transfers. They produce vibrant colors that resist fading, making them ideal for custom printed apparel that stands the test of time.

Are there tutorials available for learning DTF transfer techniques?

Yes, many online communities and platforms provide educational resources, including video tutorials and step-by-step guides on DTF transfer techniques. This wealth of information can help both DIY enthusiasts and small business owners enhance their skills in heat transfer technology.

What market trends are influencing the popularity of DTF transfers?

The increasing demand for personalized merchandise is driving the popularity of DTF transfers. As more consumers seek customized products, small businesses leveraging DTF printing technology can differentiate themselves in a competitive market and capitalize on this growing trend.

| Key Point | Description |

|---|---|

| Affordability and Accessibility | DTF printers have become more affordable, making high-quality printing options accessible to small business owners. |

| Ease of Use | The DTF transfer process is straightforward, allowing quick production of custom designs. |

| Versatility | DTF transfers work on various materials, enabling diverse product offerings. |

| Quality and Durability | DTF prints offer vibrant colors and durability, surpassing traditional printing methods. |

| Community and Education | A growing community shares resources and tips, enhancing user experiences with DTF printing. |

| Market Trends | The DTF printer market is expanding due to rising consumer demand for personalized products. |

Summary

DTF Transfers are revolutionizing the way DIY enthusiasts and small businesses approach custom printing. By providing affordable, user-friendly technology that yields high-quality, durable prints on a variety of materials, DTF Transfers empower creators to bring their unique designs to life. With a supportive community and an increasing market demand for personalized products, adopting DTF Transfers can significantly enhance a small business’s ability to innovate and grow. As the trend continues to evolve, embracing this technology will be crucial for anyone looking to stand out in a competitive market.