UV DTF Gangheet: How It Revolutionizes T-Shirt Graphics

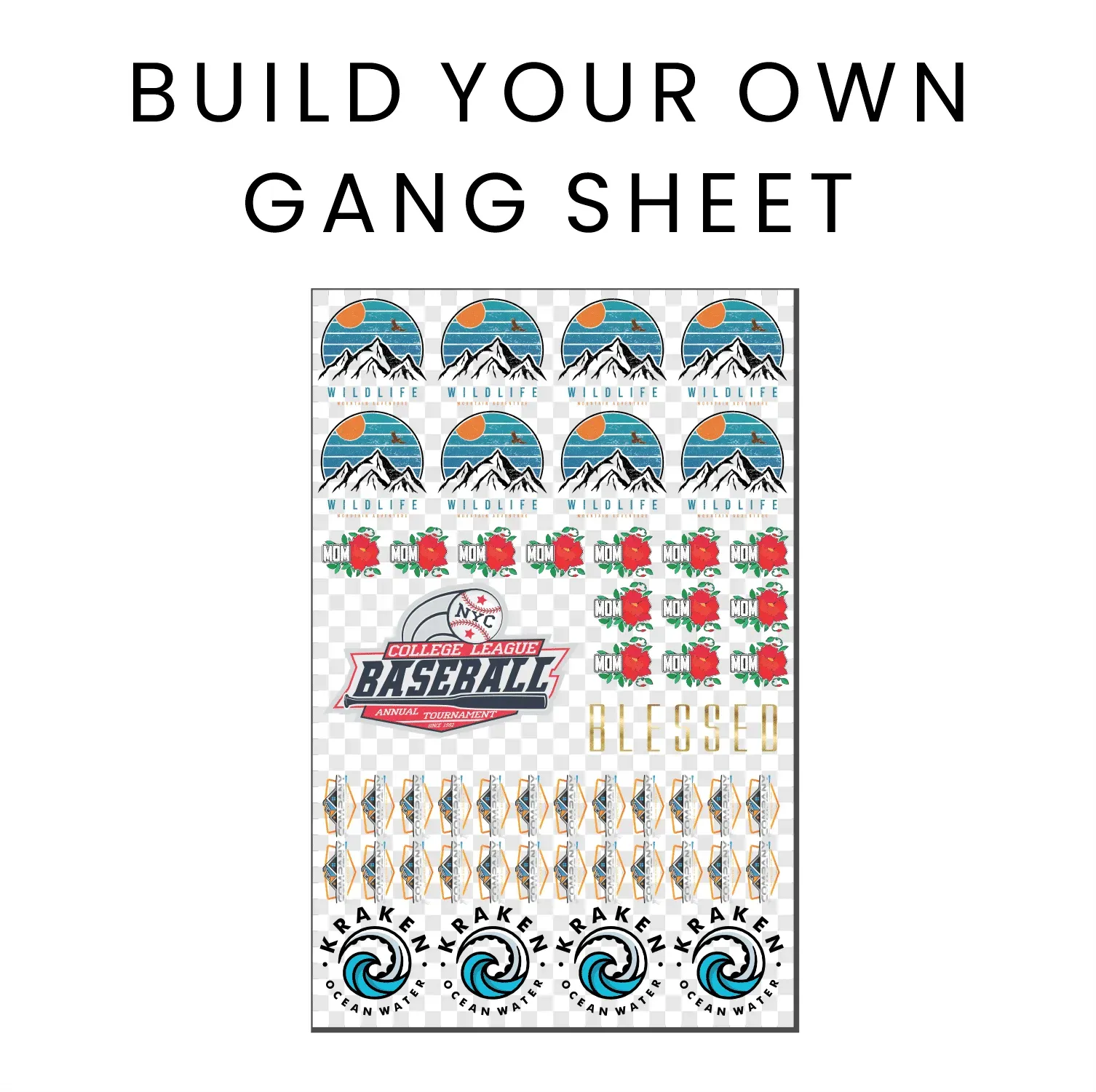

In the ever-evolving world of digital printing, **UV DTF Gangheet** emerges as a pioneer, revolutionizing the landscape of custom apparel printing. This cutting-edge UV Direct-to-Film (DTF) technology simplifies the production of vibrant T-shirt designs, allowing for intricate, high-quality graphics that can be applied to a variety of textiles. The ability to create stunning graphics for T-shirts not only enhances the visual appeal of garments but also caters to the growing demand for personalized clothing. Businesses and artists alike are embracing UV DTF printing for its versatility and durability, ensuring that their designs endure wash after wash. Join us as we delve deeper into how UV DTF Gangheet is shaping the future of graphics in the fashion industry.

As the printing industry advances, terms like UV DTF printing and textile transfer technology are gaining traction, especially for creating unique clothing items. The process of embedding colorful and durable designs onto fabrics not only increases product appeal but also empowers designers to push creative boundaries. Custom apparel solutions provided by DTF technology allow businesses to respond quickly to market trends, offering consumers tailored merchandise options. With applications ranging from fashion to promotional events, the potential for vibrant graphics on various materials has never been more accessible. Explore the transformative impact of UV DTF Gangheet and similar innovations as they redefine the way we think about and create clothing.

Understanding the Basics of UV DTF Printing

UV DTF printing, or ultraviolet direct-to-film printing, represents a significant leap in the world of custom apparel printing. This technology utilizes UV light to cure inks precisely as they are printed, enabling high-quality designs to be transferred seamlessly onto a variety of materials. Unlike traditional printing methods, UV DTF allows for greater flexibility and creativity in graphics for T-shirts, catering to both intricate designs and bold visuals. As businesses increasingly seek unique and personalized items, understanding the ins and outs of UV DTF is essential for leveraging its full potential.

In essence, UV DTF printing is a game-changer in the apparel industry, allowing creators and brands to bring their artistic visions to life. The method is not just limited to fabric; it can transfer graphics onto various surfaces, including plastics and wood, making it versatile and valuable across different markets. For t-shirt customizations, this pioneering printing technology ensures vibrant t-shirt designs that stand out, remaining crisp and alive over time unlike their screen-printed predecessors.

The Innovative Features of UV DTF Gangheet

UV DTF Gangheet exemplifies the pinnacle of innovation in digital printing, combining advanced technology with user-driven features. One of the standout aspects of this brand is its commitment to providing vibrant and durable prints. The UV curing process ensures that the graphics not only look stunning but also withstand the wear and tear commonly seen with other printing methods. This durability is particularly attractive for small businesses looking to offer high-quality merchandise without worrying about early fading or damage.

Additionally, UV DTF Gangheet places a significant emphasis on affordability, especially for small runs. Traditional printing can be cost-prohibitive for new entrepreneurs, but with UV DTF technology, businesses can produce custom designs without extensive upfront investments. This makes it easier for them to test the market with unique graphics for t-shirts, adapt their offerings quickly, and respond effectively to consumer demands.

Advantages of UV DTF Printing Over Traditional Methods

The advantages of UV DTF printing are plentiful, making it a preferred choice among graphic designers and apparel businesses. Unlike traditional screen printing, which requires multiple screens and extensive setup time, UV DTF offers faster production times and less waste, leading to more efficient processes. The ability to print intricate designs without compromising on detail is particularly beneficial for brands looking to differentiate themselves in a saturated market.

Moreover, the versatility of UV DTF technology cannot be overlooked. It allows printers to work with a wide range of materials, from cotton to polyester and even non-textile surfaces like acrylic or wood. This opens up new avenues for creativity in custom apparel printing, helping brands to develop a more comprehensive product range. As entrepreneurs explore exciting possibilities with vibrant graphics, they can elevate their brand identity through innovative print solutions.

Customization and Personalization in Apparel Design

In today’s market, the demand for custom apparel is at an all-time high, and UV DTF Gangheet is perfectly positioned to meet this need. The technology allows customers to create unique items that reflect their individual styles and preferences. Whether for corporate branding, sports teams, or personal events, the customization options are endless. Small and large businesses alike can leverage this capability to provide customers with personalized merchandise that resonates deeply with their audience.

Furthermore, the trend of personalization taps into consumers’ desires to stand out and express their identities. With UV DTF printing, businesses can easily offer tailored designs, making the shopping experience more engaging for customers. This shift towards bespoke products not only enhances consumer satisfaction but also fosters loyalty, as clients are more likely to return for more distinctive pieces that resonate with their personal tastes.

The Environmental Benefits of UV DTF Technology

As sustainability becomes a growing concern in the printing industry, UV DTF Gangheet stands out for its eco-friendly approach. The inks used in UV DTF printing are often free from solvents and harmful chemicals, aligning with environmental regulations and standards. By choosing UV DTF printing, businesses not only contribute to a greener planet but also appeal to environmentally-conscious consumers who prioritize sustainability in their purchasing decisions.

Moreover, the efficiency of UV DTF printing translates to less waste overall compared to traditional methods. The precision with which designs are printed reduces the amount of leftover materials, thereby minimizing the ecological footprint of the printing process. Brands that prioritize sustainability and make eco-friendly choices in their production processes can fortify their market position, aligning themselves with current consumer expectations and values.

Future Innovations in UV DTF Printing Technology

The future of UV DTF printing technology is brimming with potential, with ongoing innovations improving both print quality and efficiency. Advances in ink formulation promise to enhance the speed of the printing process while ensuring better adhesion across various substrates. These developments are crucial for broadening the range of materials that can be printed on, delivering even more customization options for fashion designers and brands alike.

Additionally, improvements in curing systems are expected to play a significant role in maximizing production speeds without sacrificing quality. As the technology evolves, businesses that adopt UV DTF will likely find themselves at the forefront of the industry, equipped to meet rising consumer demands for high-quality, vibrant designs. Keeping an eye on these advancements will ensure that entrepreneurs stay competitive in a fast-paced market that values both innovation and sustainability.

Frequently Asked Questions

What is UV DTF Gangheet and how does it enhance custom apparel printing?

UV DTF Gangheet represents a cutting-edge approach in the custom apparel printing arena, utilizing UV Direct-to-Film technology. This method allows for vibrant, high-quality graphics to be printed directly onto transfer films, which can then be applied to various textiles. Unlike traditional printing techniques, UV DTF printing ensures durability and color vibrancy, making it ideal for T-shirts and other apparel.

What advantages does UV DTF printing offer for vibrant t-shirt designs?

UV DTF printing provides several advantages for vibrant t-shirt designs, including exceptional color vibrancy, quick dry times, and durability. The UV curing process locks the colors in, preventing fading, cracking, or peeling, which is often seen in screen printing. This technology also supports high-resolution designs, allowing graphic designers to create intricate and visually appealing artwork for apparel.

How does UV DTF Gangheet compare with traditional screen printing methods?

UV DTF Gangheet outperforms traditional screen printing methods in several areas. It offers faster turnaround times for both small and large print runs, enhanced fabric compatibility, and longer-lasting prints. Additionally, the eco-friendly inks used in UV DTF printing cater to environmentally conscious consumers, making it a more sustainable choice for custom apparel production.

Can UV DTF technology be used on materials other than t-shirts?

Absolutely! UV DTF technology is versatile and can be applied to a wide array of materials beyond T-shirts, including bags, hats, and various textiles. This adaptability makes UV DTF printing an excellent option for creating custom designs for diverse apparel and promotional products.

Is UV DTF Gangheet technology affordable for small businesses?

Yes, UV DTF Gangheet technology is affordable for small businesses, particularly for small print runs. The reduced setup costs associated with UV DTF printing allow entrepreneurs to market their custom designs without facing high initial costs typically seen with traditional screen printing methods.

What should I consider when choosing UV DTF printing for my graphic design needs?

When choosing UV DTF printing for your graphic design needs, consider factors such as print quality, durability, production speed, and material compatibility. Also, evaluate the customization options available through UV DTF Gangheet, particularly if you’re looking to create unique and personalized apparel designs.

| Aspect | Details |

|---|---|

| What is UV DTF Printing? | A modern printing technique that utilizes ultraviolet light to cure inks on transfer film for versatile applications. |

| Key Advantages | 1. Versatile across surfaces 2. Vibrant color output 3. High durability 4. Fast production times 5. Eco-friendly inks |

| Customization and Personalization | Allows for bespoke items catering to personal styles and demands like team merchandise or events. |

| Affordability for Small Runs | Cost-effective for small batch printing, enabling startups to launch designs without high upfront costs. |

| Recent Developments | Innovations in ink formulations and curing technology improve print quality, speed, and material diversity. |

Summary

UV DTF Gangheet is transforming the printing landscape with its advanced direct-to-film printing technology, which offers numerous advantages for graphic design and apparel customization. This innovative method provides high-quality, vibrant prints on various materials, ensuring durability and fast turnaround times, making it an essential choice in the competitive apparel market. As UV DTF technology continues to develop, it promises endless possibilities for customization and serves as an eco-friendly option for businesses looking to minimize their environmental impact. By leveraging these benefits, UV DTF Gangheet is not just a trendsetter but a pivotal force in shaping the future of the industry.