UV DTF Printing: A Beginner’s Comprehensive Guide

UV DTF printing, or UV Direct-to-Film printing, is revolutionizing the landscape of custom printing solutions by combining the strengths of UV printing technology with efficient direct-to-film processes. This innovative technique allows for the instant curing of ink using ultraviolet light, resulting in stunningly vibrant and durable prints on a multitude of surfaces. As designers, businesses, and crafters increasingly embrace UV DTF printing, its textured UV printer capabilities are captivating those seeking high-quality, intricate designs for products ranging from apparel to promotional materials. The ability to produce such detailed prints with remarkable durability positions UV DTF printing as a formidable option among contemporary printing innovations. Join us as we delve deeper into this exciting printing method and explore its potential to enhance your projects.

When it comes to the latest advancements in printing, one cannot overlook the emergence of direct-to-film technology, particularly in the realm of UV printing. This method, often referred to as UV DTF, harnesses ultraviolet light for rapid ink curing, ushering in a new era for personalized printing solutions. With its ability to create detailed, textured images on various substrates, this innovative process is becoming a go-to choice for craftsmen and business owners alike. As we explore different facets of this state-of-the-art printing technique, we will uncover how it stands out in the evolving field of custom printing, offering unique benefits that cater to creative professionals and entrepreneurs.

Understanding UV DTF Printing: A Revolutionary Technique

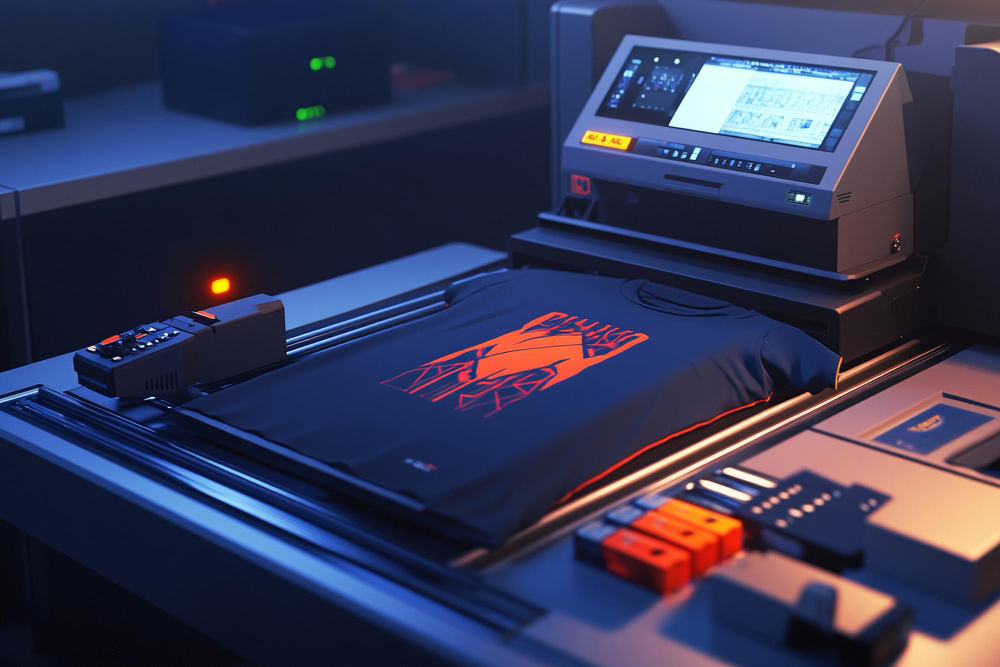

UV Direct-to-Film (DTF) printing is a state-of-the-art technique that revolutionizes the traditional printing landscape by merging advanced UV printing technology with direct-to-film processes. This innovative method employs ultraviolet light to rapidly cure inks as they are printed, resulting in striking, high-resolution images that adhere to a variety of substrates. Unlike conventional inkjet printing that often yields softer, more vulnerable prints, UV DTF provides a durable finish, ensuring designs remain vibrant and resistant to fading over time.

The intricacy of UV DTF printing lies in its ability to print on films which are later transferred to different surfaces using heat and pressure. This opens up limitless opportunities for customization, allowing businesses and designers to create unique products such as promotional materials, apparel, and crafts with precision. As a result, UV DTF printing is gaining traction among professionals for its breathtaking visual effects and the flexibility it offers in achieving high-quality print designs.

Recent Innovations in UV DTF Technology

The UV DTF printing landscape is experiencing rapid evolution, seeing a wave of exciting innovations that push the boundaries of creativity and efficiency. For instance, the introduction of the eufyMake E1, a personal 3D-texture UV printer, has transformed the accessibility of textured printing to small businesses and hobbyists. Its unique capabilities to print complex textures elevate the printing experience, allowing creators to add depth and sophistication to their projects.

Additionally, the adoption of advanced rotary printing attachments means UV DTF printers can now print on a broader array of shapes, including cylindrical objects. This enhances the versatility of UV DTF technology, making it suitable for everything from custom mugs to unique signage. Moreover, the development of UV DTF laminating machines has streamlined the production of stickers and decals, ultimately transforming how businesses can produce custom designs.

The Advantages of UV DTF Printing

One of the most appealing benefits of UV DTF printing is its remarkable versatility. Capable of printing on a diverse range of materials, including textiles, wood, metals, and ceramics, this technology is adaptable to various industries. Whether creating intricate custom apparel or detailed signage, the ability to print on different surfaces expands design possibilities beyond traditional methods. This adaptability caters to both commercial endeavors and personal projects, allowing users to explore their creativity without limitations.

Furthermore, the durability of UV DTF prints sets them apart in the marketplace. With UV curing technology, prints become resistant to wear, scratches, and fading, offering longevity even in high-traffic or outdoor settings. This durability translates into better investment for businesses seeking cost-effective solutions without compromising on quality. Speed is another standout feature, as the quick curing times significantly streamline production cycles, benefiting industries that demand rapid turnaround for projects.

Exploring Custom Printing Solutions with UV DTF

With the innovation of UV DTF printing, the landscape for custom printing solutions is rapidly expanding. Businesses and individual creators are now able to produce tailored products that meet specific customer requirements. For instance, UV DTF allows for detailed artwork, logos, and text to be rendered onto substrates in a way that traditional methods cannot match. The ability to create vibrant, high-quality prints that are fully customizable means that users can target niche markets with unique offerings.

In addition, leveraging UV DTF technology empowers businesses to meet the growing demand for personalized items. As consumers increasingly seek unique products, the versatility offered by DTF printing provides an edge to those in retail and promotional sectors. Whether it’s crafting bespoke merchandise for events or personalized gifts, UV DTF opens up avenues for companies to provide their clients with unparalleled custom options.

Industry Recognition and the Future of UV DTF Printing

As the UV DTF printing market matures, it is garnering increased recognition at major industry events like FESPA 2025. This recognition underscores the significant innovations taking place within the realm of commercial printing. Leading manufacturers are making strides to create more efficient and powerful UV DTF printers tailored for a diverse range of applications, solidifying UV printing technology as a game-changer for businesses looking to expand their printing capabilities.

The future of UV DTF printing holds great promise, suggesting that it will dominate as a preferred printing technique across various sectors. The consistent advancements being introduced, such as faster print speeds, better accuracy, and improved material compatibility, position UV DTF as a leading choice for professionals. As more creators and businesses adopt this technology, we can expect to see an increase in innovative applications that push the boundaries of what’s possible in the printing industry.

The Creative Applications of UV Printing Technology

UV printing technology is not just about creating beautiful prints; it’s about unleashing creativity in novel ways. Whether for industrial purposes or artistic endeavors, UV DTF printing allows for a broad spectrum of applications. Artists can explore detailed designs on various surfaces, leading to the creation of artwork that resonates with contemporary aesthetics. This technology has broken traditional barriers, enabling intricate work that was once thought impractical or unattainable.

Moreover, small businesses can leverage UV DTF technology to tap into emerging markets where custom or limited-edition products are highly prized. From personalized gifts to boutique packaging solutions, the applications are virtually limitless. As designers and creators become more familiar with this technology, we’re likely to see an explosion of unique, innovative products, especially crafted items that reflect their maker’s artistic vision and cater directly to customer desires.

Frequently Asked Questions

What are the key features of UV DTF printing?

UV Direct-to-Film (DTF) printing features ultra-fast ink curing using ultraviolet (UV) light, producing vibrant and durable images. This innovative method allows for printing on various substrates including textiles, ceramics, and metals, making it an ideal choice for custom printing solutions.

How does UV DTF printing differ from traditional printing methods?

Unlike traditional inkjet printing methods, UV DTF printing utilizes UV printing technology to immediately cure the ink, resulting in higher durability and resistance to fading. This direct-to-film approach allows for intricate designs and faster production speeds, enhancing the overall efficiency of custom printing projects.

What recent innovations are shaping the UV DTF printing landscape?

Recent innovations in UV DTF printing include the eufyMake E1, a textured UV printer designed for personal use, and advancements like Rotary Printing Attachments that expand the capabilities of UV DTF machines. These printing innovations increase the potential applications, catering to artists and small businesses alike.

What are the benefits of using UV DTF printing for custom apparel?

Using UV DTF printing for custom apparel offers several benefits, such as the ability to print on a wide variety of fabrics and materials, exceptional durability against wear and tear, and vibrant colors that remain intact over time. This versatility makes UV DTF a preferred method for producing high-quality custom garments.

Can UV DTF printing be used for textured designs?

Yes, UV DTF printing can be used for creating textured designs, particularly with printers like the eufyMake E1 that specialize in textured UV printing. This capability allows designers to explore new creative avenues, making it suitable for unique custom projects and artistic applications.

Is UV DTF printing suitable for large-scale production?

Yes, UV DTF printing is suitable for large-scale production, especially with advancements in printer technology that support higher output rates. The efficiency of UV curing and the ability to print on diverse materials ensure that businesses can meet high-demand printing needs while maintaining quality and speed.

| Key Points | Details |

|---|---|

| What is UV DTF Printing? | A method combining UV printing with direct-to-film applications, using UV light to cure ink for durable prints. |

| Recent Developments | Includes advancements like the eufyMake E1 printer, rotary printing attachments, and innovations showcased at industry events. |

| Benefits | Versatility with various material compatibility, durability against wear and fading, and fast production speeds. |

Summary

UV DTF printing is a revolutionary technology that has transformed the printing landscape, providing exceptional quality and versatility for various applications. This innovative approach combines the benefits of UV printing with direct-to-film techniques, allowing users to produce vibrant and long-lasting prints on multiple surfaces. The recent advancements in printer technology and expanded capabilities, such as the introduction of the eufyMake E1, highlight the growing accessibility of UV DTF printing for both artisans and businesses. Moreover, the key benefits of this technology, including its adaptability to different materials, durability, and quick production times, make it an optimal choice for creative projects. As the popularity of UV DTF printing continues to rise, it promises to unlock new possibilities and enrich the creative expression of designers and hobbyists alike.