UV DTF Technology: Transform Your Designs with Innovation

In the fast-paced world of printing and design, **UV DTF technology** represents a significant leap forward. This innovative method merges the precision of UV printing with the versatility of direct to film printing, creating endless possibilities for custom printing solutions. Users can now achieve high-quality prints on an array of surfaces, from textiles to glass, enhancing their product offerings like never before. Moreover, it provides notable environmental benefits by utilizing inks that produce fewer volatile organic compounds (VOCs), thus promoting sustainability. With its rapidly growing popularity, UV DTF technology is poised to redefine standards in high-quality printing techniques and customization.

Exploring the realm of UV Direct to Film solutions reveals a fascinating convergence of advanced printing methods. This cutting-edge technology seamlessly integrates ultraviolet ink curing with direct film transfer processes, leading to vibrant and durable outputs across various materials. Known for its adaptability, this approach opens up new avenues for bespoke printing applications and elevates the quality of printed designs. Notably, the eco-friendliness associated with UV printing aligns with the industry’s shift towards sustainability, making it a smart choice for environmentally-conscious businesses. As we delve deeper into these high-tech printing techniques, the opportunities for innovation in custom printing become abundantly clear.

Understanding the Intersection of UV Printing and DTF Technology

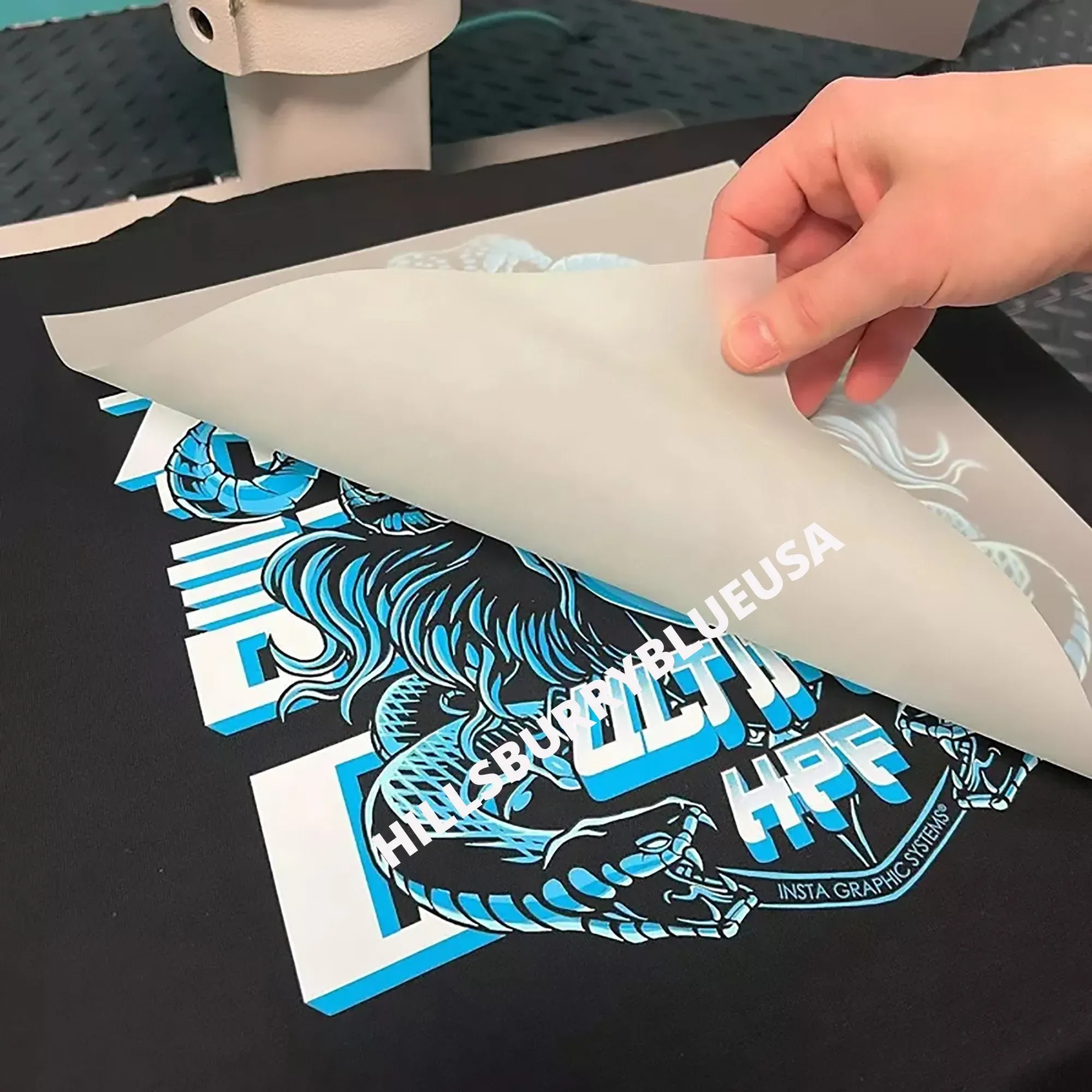

UV printing and Direct to Film (DTF) technology are two impressive printing techniques that have merged to create a powerful tool for customization. UV printing utilizes ultraviolet light to cure the inks rapidly, allowing for stunningly vibrant colors and intricate designs. This method is particularly effective as it adheres well to a plethora of surfaces, from glossy vinyl to textured fabrics. DTF, on the other hand, offers the flexibility to transfer detailed graphics onto different substrates, allowing for prints that stand out due to their depth and clarity. By combining the best aspects of both technologies, businesses are now capable of producing high-quality images efficiently, meeting the diverse needs of the market with ease.

The synergy of UV printing and DTF technology opens up new avenues for creative expression in the printing industry. This hybrid approach ensures that brands can maintain consistency in color and design integrity, which is pivotal for those in fashion and merchandise applications. Moreover, the ability to print on non-traditional materials expands product offerings, allowing for unique designs that resonate with consumers seeking personalized items. As this technology continues to evolve, it enhances the capabilities of custom printing, ultimately leading to greater consumer satisfaction and loyalty.

The Benefits of Adopting UV DTF Technology

Adopting UV DTF technology presents numerous advantages for businesses in the printing sector. One of the primary benefits is the production of high-quality prints that exhibit unparalleled vibrance and detail thanks to the UV curing process. The combination of both printing methods results in exceptional durability, meaning that finished products are not only visually appealing but also resistant to wear and tear. This is incredibly advantageous for items that are regularly used or displayed outdoors, where colors might fade under harsh conditions.

Another significant advantage of UV DTF technology lies in its cost-effectiveness. With the ability to print-on-demand, businesses can minimize waste and avoid the pitfalls of holding excess inventory. This not only streamlines operational costs but also aligns with the growing trend towards sustainable practices in manufacturing. Eco-conscious businesses can leverage the reduced volatile organic compounds (VOCs) associated with UV inks, contributing to an overall greener production model that appeals to environmentally aware consumers.

Furthermore, the versatility of UV DTF technology cannot be overstated. Industries across the board can utilize this technology to create customized items, from personalized apparel to home decor solutions. Such adaptability not only meets various consumer demands but also encourages creativity and innovation among designers, leading to unique, marketable products.

Finally, the capacity for high-quality and durable finishes means that businesses are more inclined to experiment with designs and substrates, thus fostering an environment of creativity and exploration. As a result, the opportunities for interpreting consumer trends become more abundant, equipping brands with the tools necessary to stay competitive in a crowded marketplace.

Innovations Driving UV DTF Technology Forward

Recent innovations in UV DTF technology are significantly driving forward its status in the printing industry. Equipment has improved dramatically, with new printers allowing for faster production speeds and the ability to handle more complex designs effortlessly. These advancements are crucial for small to medium enterprises, providing them with access to technology previously only available to larger companies. As print quality elevates, so does the potential for craftsmanship in custom designs, shaping the future of product offerings.

The advancements are not only technical but also focus on sustainability. The industry is making strides towards renewable resources, which has resulted in lower carbon footprints associated with traditional ink production. As companies increasingly prioritize eco-friendly practices, the integration of such innovations ensures that UV DTF technology aligns with the broader goal of enhancing environmental responsibility within the sector, appealing to both producers and consumers who prioritize sustainability.

Market Trends Shaping UV DTF Technology Adoption

Emerging market trends are contributing to the growing momentum of UV DTF technology adoption. With the rise of e-commerce and shifting consumer preferences towards personalized products, businesses are compelled to innovate continuously. A notable increase in demand for custom printing solutions for gifts and apparel has propelled this technology into the spotlight. Industry reports indicate a steady growth trajectory, suggesting that businesses failing to adopt such innovative technologies risk falling behind competitors who embrace customization and high-quality outputs.

Moreover, analysis indicates a significant market growth rate, projected to surpass 15% CAGR over the next five years. This growth is largely driven by the necessity for businesses to adapt to an ever-evolving digital marketplace, where customized and immediate solutions are not just expected but demanded. As various industries turn their focus toward incorporating UV DTF technology, they assert their relevance in a modern, personalized consumer landscape.

Exploring the Versatility of UV DTF Technology

The versatility of UV DTF technology stands at the forefront of its appeal, allowing for an incredibly broad application range. This technology enables printing on an array of substrates—such as textiles, wood, ceramics, and metal—making it a go-to choice for various industries. Products created using UV DTF can range from promotional items and branded merchandise to embellished fashion, showcasing unique designs that attract consumer attention. This flexibility positions UV DTF technology as a vital tool for businesses looking to diversify their product lines while maintaining quality.

Not only does this versatility cater to different sectors, but it also enhances the potential for creativity. Designers utilizing UV DTF technology can experiment with techniques and materials, pushing the boundaries of innovation. This adaptable approach empowers businesses to stay ahead in competitive markets by offering unique, standout products that resonate with targeted consumer demographics—a crucial advantage in today’s saturated marketplace.

Environmental Sustainability in UV DTF Processes

The ecological impact of UV DTF technology is a significant point of discussion in today’s industry. One of the most profound benefits of using UV inks lies in their low emission of volatile organic compounds (VOCs), which are often harmful to the environment. As manufacturers prioritize sustainability, the implementation of UV DTF technology reflects a commitment to eco-friendly practices. This transformation aligns with the global demand for greener operations, ensuring that businesses are contributing positively to environmental conservation.

Furthermore, ongoing research into renewable resources for inks is boosting the sustainability credibility of UV DTF technology. Innovations that explore biodegradable materials and sustainable sourcing play an essential role in reducing the overall environmental footprint of the printing process. By adopting these practices, companies not only meet consumer expectations for sustainable products but also establish themselves as leaders in the movement towards greener manufacturing, positioning themselves strongly in a competitive landscape where consumers increasingly favor eco-conscious brands.

Frequently Asked Questions

What is UV DTF technology and how does it combine UV printing and direct to film printing?

UV DTF technology is an innovative printing method that integrates UV printing’s crispness with Direct to Film (DTF) printing’s flexibility. UV printing uses ultraviolet light to cure vibrant inks on various surfaces, while DTF printing transfers high-quality images from a film. The combination allows businesses to achieve stunning and durable results on a wide range of substrates.

What are the main advantages of UV DTF technology in custom printing?

The advantages of UV DTF technology in custom printing include producing high-quality prints with vibrant colors and crisp details, offering cost-effectiveness through reduced ink waste and on-demand printing, and providing environmental benefits due to lower volatile organic compounds (VOCs) in UV inks. Additionally, its versatility and durability make it suitable for a wide array of applications.

How does UV DTF technology contribute to environmental sustainability?

UV DTF technology supports environmental sustainability by utilizing UV inks that contain fewer volatile organic compounds (VOCs), reducing harmful emissions during the printing process. Innovations in UV DTF also focus on developing renewable and sustainable ink sources, further minimizing the carbon footprint associated with traditional printing methods.

What industries can benefit from UV DTF technology’s versatility in high-quality printing?

Many industries can benefit from UV DTF technology’s versatility, including fashion, home decor, promotional products, and industrial printing. This technology enables businesses to create customized items that showcase detailed designs on various materials, such as textiles, wood, and glass, catering to diverse market needs.

What recent advancements have been made in UV DTF technology?

Recent advancements in UV DTF technology include the introduction of faster and more capable printers, making this technology accessible to small and medium-sized enterprises. Additionally, there is a growing focus on sustainability and expanding application areas, leading to innovative uses in various sectors, including fashion and furniture.

How does UV DTF technology improve the efficiency and output of custom printing operations?

UV DTF technology enhances the efficiency and output of custom printing operations by allowing for quick turnaround times with high-speed printing capabilities. The on-demand nature of UV DTF printing reduces inventory costs, while its adaptability to diverse substrates broadens the range of products businesses can offer, thus increasing overall productivity and profitability.

| Key Points | Details |

|---|---|

| Introduction to UV DTF Technology | Combines UV printing and DTF printing for customizable designs across various surfaces. |

| What is UV DTF Technology? | It integrates UV printing’s durability and quality with DTF’s vibrant transfer capabilities. |

| Advantages of UV DTF Technology | 1. High-Quality Prints 2. Cost-Effectiveness 3. Environmental Benefits 4. Versatility 5. Durability |

| Recent Developments | 1. Increased Popularity 2. Equipment Advancements 3. Market Growth 4. Sustainability Focus 5. Expanding Application Areas |

| Conclusion | UV DTF technology is set to revolutionize the printing industry, offering sustainable, high-quality, and versatile printing solutions. |

Summary

UV DTF technology is reshaping the landscape of printing by merging high-resolution UV printing with the dynamic capabilities of Direct to Film printing. This revolutionary combination allows for vibrant, customized prints that cater to diverse applications, from textiles to home decor. With its cost-effectiveness and reduced environmental impact, UV DTF technology not only enhances product offerings but also aligns with today’s demand for sustainable practices in printing. As the industry moves forward, the adoption of UV DTF technology is expected to rise, paving the way for innovative and personalized consumer products.